Abstract

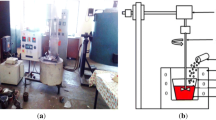

Vortex-free high-speed stir casting (VFHSC) methodology can achieve uniform dispersion of particles in melt without air entrapment for fabricating particle reinforced composites, and it has been proved to be feasible for preparing micron-composites by this methodology. In this work, in order to study deeply on particles in nano-size magnitude in composites by this methodology, the preparation of 1.5 vol.% Nano-Al2O3p/Al–Cu–Mg–Si composite is also investigated. The proper stirring parameters for ideal particle dispersion are determined to prepare the materials. Porosity of the composite can be limited to 0.147 % under the VFHSC methodology. The composition and microstructure of ingots, including the incorporation of Al2O3 particles as well as the morphology of precipitated phases, are examined by OM, XRD, SEM, TEM, HRTEM and EDS. The nano-particles are incorporated ideally in the matrix with restricted aggregation and sedimentation, and the well-bounded Al2O3–Al interface possesses semi-coherent interface. Moreover, the VFHSC 1.5 vol.% Nano-Al2O3p/Al–Cu–Mg–Si composite exhibits obvious strengthening, limited ductility reduction, higher hardness as well as better wear resistance than those of matrix, validating the efficacy of the VFHSC methodology on fabricating 1.5 vol.% Nano-Al2O3p/Al–Cu–Mg–Si composite. The work proves that incorporating nano-particles in Al matrix by VFHSC methodology is feasible and efficient. The work presented in this paper proposes a viable approach for the fabrication of nanocomposites using the stir casting method, thereby offering valuable insights for further research on stir casting technology.

Similar content being viewed by others

References

Z. Zaiemyekeh, G.H. Liaghat, H. Ahmadi et al., Effect of strain rate on deformation behavior of aluminum matrix composites with Al2O3 nanoparticles. Mater. Sci. Eng. A 753, 276–284 (2019). https://doi.org/10.1016/j.msea.2019.03.052

B. Saleh, J.H. Jiang, A.B. Ma et al., Effect of main parameters on the mechanical and wear behaviour of functionally graded materials by centrifugal casting: a review. Met. Mater. Int. 25, 1395–1409 (2019). https://doi.org/10.1007/s12540-019-00273-8

Y.F. Song, X.F. Ding, X.J. Zhao et al., The effect of SiC addition on the dimensional stability of Al-Cu-Mg alloy. J. Alloy. Compd. 750, 111–116 (2018). https://doi.org/10.1016/j.jallcom.2018.03.257

R. Roy, Nanocomposites: retrospect and prospect. MRS Online Proc. Libr. 286, 241–250 (1992). https://doi.org/10.1557/PROC-286-241

S. Komarneni, Feature article. Nanocomposites. J. Mater. Chem. 2, 1219–1230 (1992). https://doi.org/10.1039/JM9920201219

M.P. Reddy, F. Ubaid, R.A. Shakoor et al., Effect of reinforcement concentration on the properties of hot extruded Al-Al2O3 composites synthesized through microwave sintering process. Mater. Sci. Eng. A 696, 60–69 (2017). https://doi.org/10.1016/j.msea.2017.04.064

J.M. Shockley, E.F. Rauch, R.R. Chromik et al., TEM microanalysis of interfacial structures after dry sliding of cold sprayed Al-Al2O3. Wear 376–377, 1411–1417 (2017). https://doi.org/10.1016/j.wear.2016.12.052

Y.S. Yang, F.Z. Zhao, X.H. Feng, Simulation for carbon nanotube dispersion and microstructure formation in CNTs/AZ91D composite fabricated by ultrasonic processing. Metall. Mater. Trans. B 48, 2256–2266 (2017). https://doi.org/10.1007/s11663-017-1047-0

N. Sirajudeen, M.A. Rahman, Influence of aging and mass fraction of Al2O3 on mechanical properties of Al6082/Al2O3 composite produced by stir casting. Met. Sci. Heat Treat. 62, 205–209 (2020). https://doi.org/10.1007/s11041-020-00536-x

Besekar, M. Kathiresan, R.J. Immanuel, Friction stir processing of recycled titanium reinforced A356 composite developed through stir casting. Trans. Indian Inst. Met. (2023). https://doi.org/10.1007/s12666-023-03208-5

R. Arunachalam, P.K. Krishnan, R. Muraliraja, A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 42, 213–245 (2019). https://doi.org/10.1016/j.jmapro.2019.04.017

J. Karloopia, S. Mozammil, P.K. Jha, Influence of in situ titanium diboride particulate reinforcement on mechanical properties of aluminum–silicon based metal matrix composites. J. Miner. Met. Mater. Soc. 72, 2927–2936 (2020). https://doi.org/10.1007/s11837-020-04245-x

S. Mozammil, J. Karloopia, P.K. Jha, Studies on porosity of Al-4.5%Cu-2.5pTiB2 in situ composites. Mater. Sci. Forum. 928, 51–5 (2018). https://doi.org/10.4028/www.scientific.net/MSF.928.51

S. Mozammil, J. Karloopia, R. Verma et al., Effect of varying TiB2 reinforcement and its ageing behaviour on tensile and hardness properties of in-situ Al-4.5%Cu-xTiB2 composite. J. Alloy. Compd. 793, 454–466 (2019). https://doi.org/10.1016/j.jallcom.2019.04.137

J. Karloopia, S. Mozammil, P.K. Jha, Machinability, modelling and statistical analysis of in-situ Al–Si–TiB2 composites. J. Compos. Sci. (2019). https://doi.org/10.3390/jcs3010028

J. Karloopia, S. Mozammil, P.K. Jha, An experimental study on friction stir welding of Al-Si-TiB2 metal matrix composite. Mater. Proc. 5, 17260–17269 (2018). https://doi.org/10.1016/j.matpr.2018.04.137

J. Karloopia, S. Mozammil, P.K. Jha, The abrasive wear behavior of in situ processed aluminum alloy metal-matrix composites. Met. Matrix Compos. (2022). https://doi.org/10.1007/978-3-030-92567-3_1

M. Balakrishnan, I. Dinaharan, R. Palanivel et al., Influence of friction stir processing on microstructure and tensile behavior of AA6061/Al3Zr cast aluminum matrix composites. J. Manuf. Process. 38, 148–157 (2019). https://doi.org/10.1016/j.jmapro.2018.12.039

S. Naher, D. Brabazon, L. Looney, Computational and experimental analysis of particulate distribution during Al–SiC MMC fabrication. Compos. Part A Appl. Sci. Manuf. 38, 719–729 (2007). https://doi.org/10.1016/j.compositesa.2006.09.009

Q.Y. Hu, H.D. Zhao, F.D. Li, Microstructures and properties of SiC particles reinforced aluminum-matrix composites fabricated by vacuum-assisted high pressure die casting. Mater. Sci. Eng. A 680, 270–277 (2017). https://doi.org/10.1016/j.msea.2016.10.090

Z.R. Hu, Z.K. Wu, S.C. Luo et al., Large scale production of graphene aluminum composites by stir casting: Process, microstructure and properties. J. Mater. Res. Technol. 27, 681–691 (2023). https://doi.org/10.1016/j.jmrt.2023.09.298

P. Zhang, W.Y. Zhang, Y.H. Du et al., High-performance Al-1.5 wt% Si-Al2O3 composite by vortex-free high-speed stir casting. J. Manuf. Process. 56, 1126–1135 (2020). https://doi.org/10.1016/j.jmapro.2020.06.016

W.Y. Zhang, Y.H. Du, P. Zhang, Vortex-free stir casting of Al-1.5 wt% Si-SiC composite. J. Alloy. Compd. 787, 206–215 (2019). https://doi.org/10.1016/j.jallcom.2019.02.099

W.Y. Zhang, Y.H. Du, P. Zhang et al., Air-isolated stir casting of homogeneous Al-SiC composite with no air entrapment and Al4C3. J. Mater. Process. Technol. 271, 226–236 (2019). https://doi.org/10.1016/j.jmatprotec.2019.04.001

Y.H. Du, P. Zhang, W.Y. Zhang et al., Distribution of SiC particles in semisolid electromagnetic-mechanical stir-casting Al-SiC composite. China Foundry. 15, 351–357 (2018). https://doi.org/10.1007/s41230-018-8086-2

S.I. Martynov, L.Y. Tkach, Simulation of particle aggregate dynamics in a viscous fluid. Comput. Math. Math. Phys. 55, 282–290 (2015). https://doi.org/10.1134/S0965542515020141

G.C. Chen, X.C. Li, Effect of TiC nano-treating on the fluidity and solidification behavior of aluminum alloy 6063. J. Mater. Process. Technol. (2024). https://doi.org/10.1016/j.jmatprotec.2023.118241

C.Y. Yue, B.W. Zheng, M. Su et al., Effect of Cu/Mg ratio on the intermetallic compound and hot tearing susceptibility of Al–Cu–Mg alloys. Inter. J. Metalcast. 18, 417–430 (2024). https://doi.org/10.1007/s40962-023-01033-6

J. Schmitz, I. Egry, J. Brillo, Anisotropy in wetting of oriented sapphire surfaces by liquid Al–Cu alloys. J. Mater. Sci. 49, 2286–2297 (2014). https://doi.org/10.1007/s10853-013-7925-1

X. Li, B.Q. Xiong, Y.A. Zhang et al. Influence of Silicon Addition on Precipitation Behavior in an Al-Cu-Mg Alloy. In: H. Weiland, A.D. Rollett, W.A. Cassada, (eds) ICAA13 Pittsburgh. Springer, Cham. (2012). https://doi.org/10.1007/978-3-319-48761-8_198.

H.Z. Tan, Research on preparation and properties of nNano-Al2O3p/Al composites. M.Eng thesis. Beijing Jiaotong University, (2023). https://doi.org/10.26944/d.cnki.gbfju.2023.002031

A. Budiyanto, B. Sugiarto, B. Anang, Multidimensional CFD Simulation of a Diesel Engine Combustion: A Comparison of Combustion Models. In: Proceedings of the FISITA 2012 World Automotive Congress. Lecture Notes in Electrical Engineering, vol 190. Springer, Berlin, Heidelberg. (2013). https://doi.org/10.1007/978-3-642-33750-5_5.

S. Amirkhanlou, B. Niroumand, Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods. Trans. Nonferrous Met. Soc. China 20, s788–s793 (2010). https://doi.org/10.1016/S1003-6326(10)60582-1

N. Valibeygloo, R.A. Khosroshahi, R.T. Mousavian, Microstructural and mechanical properties of Al-4.5wt% Cu reinforced with alumina nanoparticles by stir casting method. Int. J. Miner. Metall. Mater. 20, 978–985 (2013). https://doi.org/10.1007/s12613-013-0824-2

X.M. Fan, L.J. Xu, S.Z. Wei et al., Mechanical properties and strengthening mechanism of the hydrothermal synthesis of nano-sized α-Al2O3 ceramic particle reinforced molybdenum alloy. Ceram. Int. 46, 10400–10408 (2020). https://doi.org/10.1016/j.ceramint.2020.01.038

Z.Z. Xu, Y.T. Zhao, X.Z. Kai et al., Microstructures and mechanical properties of the in-situ formed nanocomposites of (ZrB2 + Al2O3) and AA7055 alloy. Mater. Lett. (2022). https://doi.org/10.1016/j.matlet.2022.132021

M.S. Szczerba, S. Kopacz, M.J. Szczerba, A study on crystal plasticity of face-centered cubic structures induced by deformation twinning. Acta Mater. 197, 146–162 (2020). https://doi.org/10.1016/j.actamat.2020.07.040

J.H. Zhang, A.Q. Wang, T.T. Liang et al., The prediction of Al2Cu/Cu interfacial structure and properties: a first-principles study. Phys. B Condens. Matter. (2023). https://doi.org/10.1016/j.physb.2023.414931

H.Y. Yang, K.Q. Li, Y.Q. Bu et al., Nanoprecipitates induced dislocation pinning and multiplication strategy for designing high strength, plasticity and conductivity Cu alloys. Scr. Mater. (2021). https://doi.org/10.1016/j.scriptamat.2021.113741

A. Mazahery, M.O. Shabani, Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting. Trans. Nonferrous Met. Soc. China 23, 1905–1914 (2013). https://doi.org/10.1016/S1003-6326(13)62676-X

Funding

This work was financially supported by the National Natural Science Foundation of China (No. 50974010), the Beijing Natural Science Foundation (No. 2162036) and the Natural Science Project of Beijing Jiaotong University (M21L00920).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, Y., Du, Y., Zhang, W. et al. Nano-Al2O3 Particle Incorporated in Al Matrix Composite by Vortex-Free High-Speed Stir Casting. Inter Metalcast (2024). https://doi.org/10.1007/s40962-024-01345-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-024-01345-1