Abstract

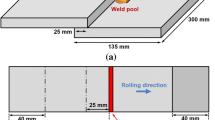

A normalized fine grain carbon low alloy steel, P355NL1 (EN10028-3), intended for service in welded pressure vessels, where notch toughness is of high importance, has been investigated. Applications with this steel usually require the intensive use of welds. One of the most common welding processes that are used in the manufacturing of pressure vessels is the submerged arc welding. This welding process is often automated in order to perform the main seam welds of the body of the vessels. The influence of the automated submerged arc welding, in the mechanical performance, is investigated. In this paper (Part II) the low and high cycle fatigue and crack propagation behaviours are compared between the base and welded materials. Several series of small and smooth specimens as well as cracked specimens made of base, welded and heat affected materials, respectively, were fatigue tested. Strain, stress and energy based relations for fatigue life assessment, until crack initiation, are evaluated based on experimental results and compared between the base and welded materials. Finally, the fatigue crack propagation behaviours are compared between the base, welded and heat affected materials.

Similar content being viewed by others

References

Taylor N et al (2001) Pressure components fatigue design in the framework of directive 97/23/EC on pressure equipment, Final Report EC DG-ENTR

EUROPEAN COMMISSION, Pressure components fatigue design in the framework of directive 97/23/EC on pressure equipment (2001), Final Report DG-JRC/IAM, http//www.ped.eurodyn.com, as on 10 June 2005

ASME Boiler and Pressure Vessel Code—Section VIII: Rules for Construction of Pressure Vessels, Division 2 – Alternative rules, Appendix 5: Design Based on Fatigue Analysis, ASME Standards (2001)

PD 5500—Specifications for Unfired Fusion Welded Pressure Vessels, British Standards (2003)

Unfired Pressure Vessels, European Standards 13445 (2002)

Radaj D, Sonsino CM (1998) Fatigue assessment of welded joints by local approaches. Abington Publishing, Abington, UK

Tricoteaux A, Fardoun F, Degallaix S, Sauvage F (1995) Fatigue Fract Eng Mat Struct 18:189

De Jesus AMP (2004) PhD Thesis, University of Trás-os-Montes e Alto Douro, Portugal

Dijkstra OD, Snijder HH, Overbeeke JL, Wildschut H (1987) In: Proceedings of the SIMS’87 conference, Delft, The Netherlands

Dijkstra OD, van Straalen IJJ, Noordhoek C (1993) In: Proceedings of the OMAE ’93 conference, Glasgow, Scotland

De Jesus AMP, Ribeiro AS, Fernandes AA (2006) J Press Vess Technol 128:298

De Jesus AMP, Ribeiro AS and Fernandes AA (2006) Soldagem Insp 11:222

Coffin LF (1954) Transl ASME 76:931

Manson SS, National Advisory Committee for Aeronautics – NACA (1953), Technical Report No.1170

Basquin OH (1910) Proc ASTM 10:625

Morrow JD, in Internal Friction, Damping and Cyclic Plasticity, ASTM, Philadelphia, 1965, p.45, ASTM STP 378

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge UK

Halford GR (1966) J Mater 1:3

Lefebvre D, Ellyin F (1984) Int J Fatigue 6:9

Ellyin F, Kujawski D (1984) J Press Vess Technol 106:342

Golos K, Ellyin F (1988) J Press Vess Technol 110:36

Ellyin F (1997) Fatigue damage, crack growth and life prediction. Chapman & Hall, London, UK

Ribeiro AS (1993) PhD Thesis, University of Trás-os-Montes and Alto Douro, Portugal

Sanford RJ (1997) Selected papers on foundations of linear elastic fracture mechanics - Volume CP1. SEM Classic Papers, Bethel, Connecticut, USA

Paris PC, Gomez MP, Anderson WE (1961) Trend Eng 13:9

Paris PC, Erdogan F (1963) J Basic Eng 85:528

Walker EK (1970) in Effects of environment and complex load history on fatigue life, ASTM, Philadelphia, 1970, ASTM STP 462

Hoeppner DW, Krupp WE (1974) Eng Fract Mechanics 6:47

Flat Products Made of Steels for Pressure Purposes - Part 3: Weldable Fine Grain Steels, Normalized, European Standards 10028–3 (2003)

Weldable Normalized Fine Grain Structural Steels. Technical Delivery Conditions for Plate, Strip, Wide Flats, Sections and Bars, Deutsche Norm 17102 (1983)

Standard Practice for Strain-Controlled Fatigue Testing, ASTM standards E606-92 (1998)

ASTM, American Society for Testing and Materials (1999) ASTM E647: standard test method for measurement of fatigue crack growth rates, in Annual Book of ASTM Standards, Vol. 03.01, ASTM, West Conshohocken, PA, pp 591–629

Maddox SJ (1974) Weld J 53:401

James LA (1977) Weld J 56:386

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

De Jesus, A.M.P., Ribeiro, A.S. & Fernandes, A.A. Influence of the submerged arc welding in the mechanical behaviour of the P355NL1 steel—part II: analysis of the low/high cycle fatigue behaviours. J Mater Sci 42, 5973–5981 (2007). https://doi.org/10.1007/s10853-006-1111-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1111-7