| Open Access | Peer Reviewed | Original Research |

Postharvest Respiration Rate, Physiological Weight Loss and Physico-chemical Quality of Mango Fruit as Influenced by Different Hot Water Quarantine Treatments under Simulated Shipment Conditions

ABSTRACT

Extended hot water quarantine treatment (HWQT) is a commercial phytosanitary measure used for fruit fly disinfestation in mangoes. These studies were targeted to evaluate the physiological behaviour and qualitative response of hot water treated fruits of late maturing mango cv. Sufaid Chaunsa under two different commercial shipment conditions including ambient shipment (28 ± 2 °C; 60-65% RH; simulated for air freight) and refrigerated shipment (10 ± 1 °C; 80-85% RH; simulated for containerized shipments through sea-freight or land routes). The fruits were harvested at physiological maturity, de-sapped (0.5% lime; 2-3 min dip), precooled to 20 °C (forced-air cooling), transported (350 km) in a reefer van (at 20 ± 1 °C), and subjected to two HWQT protocols i.e. 48 °C for 60 min and 45 °C for 75 min in comparison with control. HWQTs were found to have significant impact on physiological aspects of the fruits with significantly more weight loss and higher rate of respiration as compared to control. The fruits subjected to 48 °C for 60 min had more weight loss and higher respiration rate as compared to those at 45 °C for 75 min. Water temperature was found more critical than the treatment duration in causing fruit weight loss. HWQT protocols did not have negative impact on physico-chemical fruit quality attributes under both shipment conditions. Based upon respiratory peak, 3 weeks storage at 10 ± 1 °C; 80-85% RH was found better along with 7 days post-shipment shelf life as it maintained better eating quality at retail. The turnout is expected to be much better at neighbouring export destinations (situated at less transition/transport periods); however, the inclusion of disease control strategies at pre and postharvest levels is indispensable for low temperature shipments.

INTRODUCTION

Pakistan is one of the major mango producing countries in the world with 169.2 thousand hectare area and 1685.3 thousand tons production (FAOSTAT, 2017). The share of Pakistan in global mango exports is more than 100 thousand tons by volume with about 60 million USD earnings through these exports. The mango fruit exports from Pakistan are directed to various countries around the globe including Europe, Middle East, Central Asia, Canada and Australia. There are specific requirements for export of Pakistani mangoes to different countries.

Various quarantine treatments are used for exporting mangoes including heat treatments e.g. hot water treatment (HWT), vapor heat treatment (VHT), forced air heating and irradiation (Porat et al., 2000; Jacobi et al., 2001a; Sharp and Heather, 2002; Moy, 2005; Armstrong and Follett, 2007; Singh and Saini, 2014). Hot water treatment (HWT) involves immersion of fruits in hot water with static or flow-through systems for extended time which leads towards heat transfer from water to the skin and flesh of the fruits (Jordan, 1993). Short-term HW dip treatment for 3-5 minutes is used against the fungal infections prevailing in fruit skin e.g. anthracnose. Postharvest applications of various fungicides are practiced as hot water dip or spray for disease control. The hot water quarantine treatment (HWQT) is applied for extended time (around one hour) mainly to kill the fruit fly larvae and eggs. This technology has got significant recognition for fruit fly disinfestation (Nascimento et al., 1992; Follett and Neven, 2006) and is globally accepted to disinfest mangoes (Sharp, 1993). It is important for the mango producing countries like Pakistan due to economic advantage and competitive performance as compared to various other advanced techniques. VHT is a type of heat treatment in which water vapours are used for a specific period of time to kill the insect eggs and adult stages for mango shipments (Le et al., 2010). For export of Pakistani mangoes to Japan and Korea, the fruits are subjected to VHT at 47 ℃ for 25 minutes. The use of vapor heat treatment and forced air heating is limited due to huge installation costs (Jacobi et al., 2001a). The use of irradiation as a quarantine treatment is not fully established due to several health and safety related obstacles (Julius, 1999; Moy, 2005). Many markets/countries are still reluctant to purchase the irradiated fresh produce. The use of chemical treatments is also being restricted due to health hazardous residual concerns (Jacobi and Wong, 1992).

Pakistan deliberately supports and accepts the international phytosanitary legislations for worldwide food safety insurance (Anwar and Malik, 2007). Under this perspective, Pakistan has signed HWQT protocols with Australia, China, Jordon, Lebanon, South Korea and Mauritius (48 °C for 60 min) and Iran (45 °C for 75 min) for exporting mangoes to these countries (Malik et al., 2013). Further, for export to the countries which have not signed any phytosanitary treatment protocol with Pakistan, the government of Pakistan has imposed hot water treatment (48 °C for 60 min) as a mandatory quarantine treatment. Hence, HWQT has been adopted as a commercial fruit fly disinfestation treatment in Pakistan. Thus, there is need to evaluate the response of mango cultivars grown in Pakistan towards commercial HWQT. Some information exists for the influence of short-term HW dip (3-5 min) of Pakistani mangoes (Faheem et al., 2012). The responses of HW phytosanitary treated Sindhri (Anwar and Malik, 2007) and Sufaid Chaunsa (Jabbar et al., 2011) mangoes have been evaluated under reefer storage; while information lacks regarding extended heat treatment effect dynamics on physiological aspects. This study was conducted based upon the hypothesis that the HWQT does influence the physiological aspects and quality of mango cv. Sufaid Chaunsa under simulated airfreight (ambient) and refrigerated shipment (low temperature storage) conditions.

MATERIALS AND METHODS

Physiologically mature, uniform sized and healthy fruits of mango cv. Sufaid Chaunsa were harvested from a commercial mango orchard located in district Lodhran (latitude: 29°32`N; longitude: 71°30`E), Pakistan, along with 4-6 cm long pedicels intact and de-sapped (0.5% lime solution, 2-3 min). The fruits were dried under shade, packed in plastic bins and transported (in a reefer van at 20 °C) to Postharvest Research and Training Centre (PRTC), Institute of Horticultural Sciences, University of Agriculture, Faisalabad. On arrival at PRTC, the fruits were subjected to two different HWQT protocols i.e. 48 °C for 60 min and 45 °C for 75 min. Fruits in control treatment were not treated with any HWQT. The treated fruits were divided into two lots (i.e. for simulated ambient and refrigerated shipment conditions). The fruits for refrigerated shipment studies were additionally subjected to fungicidal treatments (Sportak @ 0.5 mL L-1; a.i. Prochloraz) in order to minimize the risk of disease outbreak under high humidity storage conditions. For ambient shipment assessments, the fruits were kept at 28 ± 2 °C; 60-65% RH after HWQTs along with control, whereas for refrigerated shipment assessments, the fruits were stored at 10 ± 1 °C (80-85% RH) for 28 and 35 days, followed by shelf life studies at ambient conditions (28 ± 2 °C; 60-65% RH).

Physiological assessments

Physiological assessments included fresh weight loss and respiration both under ambient and refrigerated shipment conditions. Fruit weight loss was calculated using formula (Weight loss/Initial weight) × 100, whereas fruit respiration was determined as CO2 (%) using a digital CO2 Gas Analyzer (MI-70; VAISALA; Finland) and converted into millimole (mmol) CO2 kg-1 h-1 (Hameed et al., 2010).

Physico-chemical quality and disease assessments

The studied physico-chemical parameters included peel colour, firmness, total soluble solids (TSS; °Brix), titratable acidity (%), TSS/Acid ratio, vitamin-C (mg/100 g), reducing, non-reducing and total sugar contents (%). Fruit peel colour was rated as 1= 100% green, 2= 1-25% yellow, 3= 26-50% yellow, 4= 51-75% yellow and 5= 75-100% yellow, and fruit firmness was assessed on the basis of textural softness score i.e. 1= hard, 2= sprung, 3= slightly soft, 4= eating soft and 5= over ripe (Miller and McDonald, 1991; Malik and Singh, 2005). Juice TSS was determined using digital stage refractometer (Atago, RX 5000, Japan) (Khan et al., 2018). Total titratable acidity and sugars (total sugars, reducing and non-reducing sugars) were determined by the method stated by Hortwitz (1960). Vitamin C content was determined by 2, 6-dichlorophenol indophenol’s titration method as stated by Ruck (1969). Severity of various postharvest diseases including anthracnose, stem end rot and side rot was rated as 1= Nil; 2= <5%; 3= 5-10%; 4= 10-25% and 5= >25% affected area while disease incidence (%) was calculated using a formula i.e. (No. of affected fruits/Total No. of fruits) × 100 (Amin et al., 2008).

Statistical analysis

The data were statistically analysed using MStat-C software (Russel and Eisensmith, 1983) under Completely Randomized Design (CRD) along with respective factorial arrangements and three replicates. Significant differences (Fisher’s protected LSD) among the means were calculated using LSD test (Steel et al., 1997).

RESULTS

Effect of HWQTs on physiological aspects of fruits under ambient and refrigerated shipment conditions

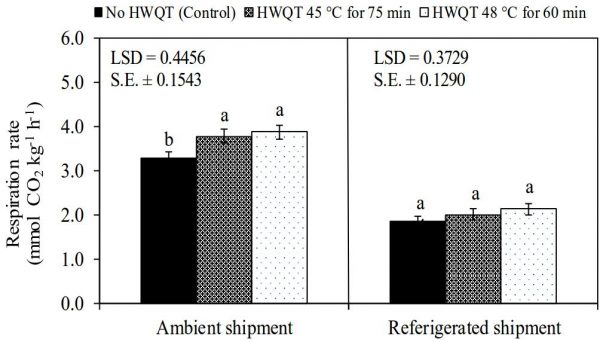

HWQTs were found to cause significant increase in rate of mango fruit respiration (i.e. CO2 liberation) under post-treatment ambient shipment/air-freight conditions as compared to control (0.51 and 0.60 mmol more CO2 kg-1 h-1, respectively) (Fig. 1). Under post-treatment low temperature storage/refrigerated shipment conditions, non-significant differences were found among the HWQTs and control (Fig. 1). Overall, the fruits subjected to HWQT at 48°C for 60 min had comparatively higher rate of respiration as compared to at 45 °C for 75 min and control (i.e. 0.13 and 0.29 mmol more CO2 kg-1 h-1 than at 45 °C for 75 min and control, respectively) (Fig. 1).

Figure 1: Mean respiration rate in mango cv. Sufaid Chaunsa fruits with respect to different HWQTs under ambient (28 ± 2 °C; 60-65% RH; simulated for air freight) and refrigerated shipment conditions (10 ± 1 °C; 80-85% RH; simulated for containerized shipments through sea-freight or land routes), (P ≤ 0.05; n = 15).

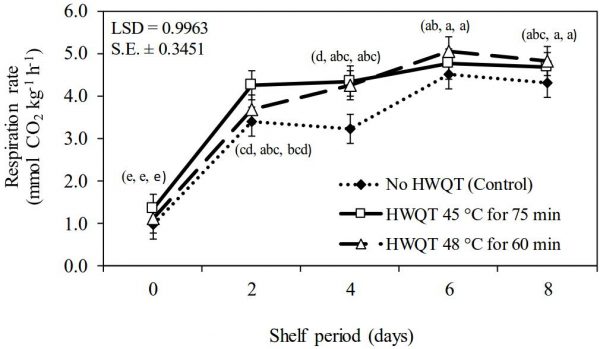

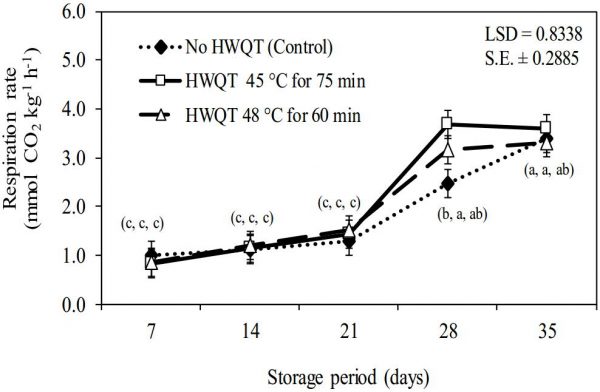

In both HWQTs and control; the climacteric peak in the fruit respiration under ambient shipment conditions was observed on 6th day of shelf (4.5, 4.8 and 5.1 mmol CO2 kg-1 h-1 in control, 45 °C for 75 min and 48°C for 60 min, respectively) (Fig. 2). Under low temperature storage/refrigerated shipment conditions, non-significant change in the rate of respiration was found up to 3 weeks (21 days). However, increase was noted at the end of 4th week with significantly higher rate in fruits subject to 45 °C for 75 min followed by 48 °C for 60 min and control (1.2 and 0.5 mmol more CO2 kg-1 h-1 than 48 °C for 60 min and control, respectively). Moreover, non-significant differences in respiration of HWQTs as well as control were recorded after 5 weeks of low temperature storage (Fig. 3).

Figure 2: Respiration rate in mango cv. Sufaid Chaunsa fruits with respect to different HWQTs at different ambient shelf periods (28 ± 2 °C; 60-65% RH; simulated for air-freight). The letter sets at each data point (left to right) indicate the statistical difference or similarity among different quarantine treatments, (P ≤ 0.05; n = 3).

Figure 3: Respiration rate in mango cv. Sufaid Chaunsa fruits with respect to different HWQTs at different low temperature storage periods (10 ±1 °C; 80-85% RH; simulated for refrigerated container shipments through sea-freight or land routes). The letter sets at each data point (left to right) indicate the statistical difference or similarity among different quarantine treatments, (P ≤ 0.05; n = 3).

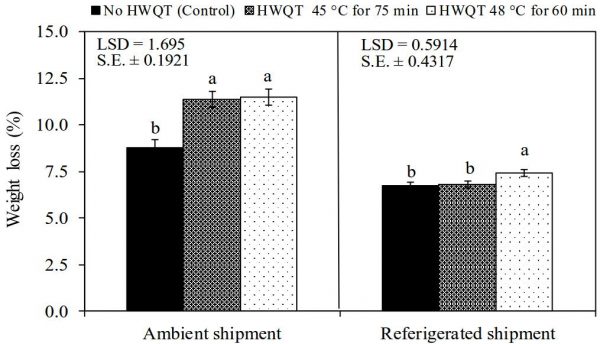

Significant impact of HWQTs was observed on fresh weight loss both under ambient and refrigerated shipment conditions (Fig. 4). After seven days (on 8th day) of ambient and air-freight conditions, the fruits subjected to HWQT at 45 °C for 75 min and 48 °C for 60 min had significantly higher weight loss as compared to control (2.6% and 2.7% more, respectively). While in case of low temperature storage/sea-freight, weight loss in the fruits of 45 °C for 75min was statistically at par with control but significantly higher in case of 48 °C for 60 min (0.7% more than 45 °C for 75 min and control).

Figure 4: Mean weight loss in mango cv. Sufaid Chaunsa fruits with respect to different HWQTs under ambient (28 ± 2 °C; 60-65% RH; simulated for air freight) and refrigerated shipment conditions (10 ± 1 °C; 80-85% RH; simulated for containerized shipments through sea-freight or land routes), (P ≤ 0.05; n =3).

Impact of HWQTs on quality and disease development in fruits under ambient and refrigerated shipment conditions

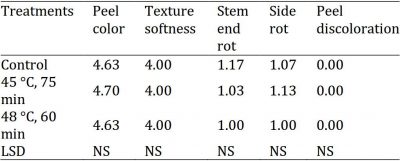

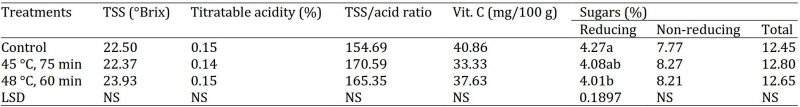

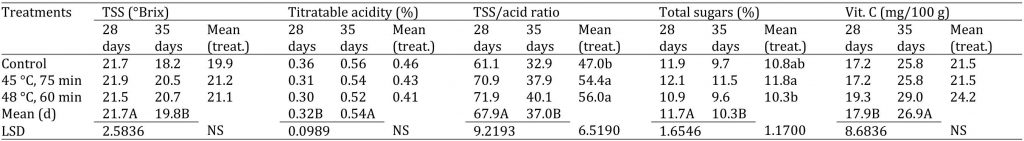

Under both conditions (ambient/air-freight and low temperature storage/refrigerated shipment), almost all of the physico-chemical fruit quality attributes showed non-significant differences among the HWQTs as well as control except reducing sugars under ambient handling (Table 2) and TSS/Acid ratio under low temperature storage (Table 4). In case of ambient handling, less reducing sugar content was recorded in both HWQTs as compared to control (significantly less content in case of 48 °C for 60 min only) (Table 2). In case of refrigerated shipment, TSS/acid ratio was found to be significantly higher in the both HWQTs (45 °C for 75 min: 54.4 and 48 °C for 60 min: 56.0) as compared to control (47.0) (Table 4).

Table 1: Physico-chemical quality of ripe mango cv. Sufaid Chaunsa fruits in relation to HWQTs under ambient/air-freight conditions (28 ± 2 °C; 60-65% RH).

Means with different letters are significantly different (P ≤ 0.05); NS: Non-significant.

Table 2: Biochemical quality of ripe mango cv. Sufaid Chaunsa fruits in relation to HWQTs under ambient shipment conditions (28 ± 2 °C; 60-65% RH).

Means with different letters are significantly different (P ≤ 0.05); NS: Non-significant.

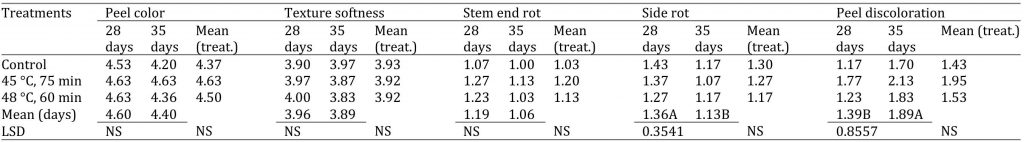

Significant variation in various physical (fruit side rot, skin discoloration) and biochemical fruit quality (TSS, titratable acidity, TSS/acid ratio and total sugars) attributes was recorded at different low temperature storage durations (Table 3 and 4). Significant incidence of fruit side rot and skin discoloration was observed in both after 28 days (4 weeks) and 35 days (5 weeks) of low temperature storage (Table 3). The fruits removed from cold store after 28 days of storage were better in terms of biochemical fruit quality due to significantly higher total soluble solids, TSS/acid ratio and total sugar content and less titratable acidity (Table 4). Vitamin-C content was found significantly higher in the fruits removed after 35 days storage as compared to 28 days from low temperature storage (Table 4).

Table 3: Physical quality of ripe mango cv. Sufaid Chaunsa fruits in relation to HWQTs under refrigerated shipment conditions (10 ± 1 °C; 80-85% RH).

Means with different letters in a group are significantly different (P ≤ 0.05).

Table 4: Biochemical quality of ripe mango cv. Sufaid Chaunsa fruits in relation to HWQTs under refrigerated shipment conditions (10 ± 1 °C; 80-85% RH).

Means with different letters in a group are significantly different (P ≤ 0.05).

DISCUSSION

Impact of treatments on fruit physiology

Significantly higher rate of respiration (Fig. 1) and greater weight loss (Fig. 4) in the fruits subjected to HWQTs as compared to control indicate the increased rate of physiological processes of HW treated fruits (Jacobi et al., 2001b). Among the two HWQTs, relatively higher weight loss in case of 48 °C for 60 min as compared to the fruits subjected to HWQT at 45 °C for 75 min highlights the importance of HWQT temperature. It clearly indicates that HWQT temperature is more critical factor as compared to the duration of treatment having significant effect on the physiological processes taking place inside the fruit body (reciprocal to the impact on fruit firmness). Thus, higher be the HWQT temperature, more will be physiological interruption resulting in higher rate of respiration (Ponce-de-Leon et al., 1997) which leads towards higher weight loss due to physiological breakdown. The role of hot water with plant and fruit physiology is evident in existing literature (Perini et al.,. 2017; Vilaplana et al., 2018)

Moreover, significantly lower rate of respiration and less weight loss under the low temperature storage conditions (10 ± 1 °C; 80-85% RH) as compared to ambient conditions (28 ± 2 °C; 60-65% RH) indicate the importance of low temperature in extending marketable life of mangoes (Fig. 1 and 4). Hence, low temperature shipping not only entertains the stakeholders with its already established benefits i.e. low transport costs and possibility of bulk exports (Malik et al., 2010), rather it also helps to extend shelf life by reducing the destructive processes i.e. respiration and weight loss. The higher rate of respiration and more weight loss under ambient conditions highlight the importance of temperature management along the supply chains for minimal fresh weight loss and reduced rate of respiration for extended shelf life.

The climacteric peak observed in the fruits respiration on 6th day of storage under ambient conditions and rise in the rate of respiration upon 4th weeks of low temperature storage suggest to schedule the arrival of commercial consignments at export destinations within 6 days of harvest for air-freights and within 21 days of harvest in case of sea-freights (Fig. 2 and 3).

Impact of treatments on fruit quality

According to previous reports, decrease in fruit firmness (Yahia and Pedro-Campos, 2000; Jacobi et al., 2001b) and increase in peel colour (Jacobi and Wong, 1991; Anwar and Malik, 2006) has been observed in response to hot water treatments. However, in this study, non-significant differences among the HWQTs regarding fruit peel colour and firmness (Table 1 and 3) showed least involvement of the studied HWQT protocols in the process of textural softness and peel colour development (Lizada et al., 1986; Govender et al., 2005). The response towards HWQT may vary among mango cultivars depending upon their genetic potential, as our research trials on other mango cultivars (e.g. Sindhri) did not show fruit skin discoloration under low temperature storage. The hot water treatments were also found to have non-significant effect on fruit body rots i.e. stem end rot (SER) and side rots (Table 1 and 3). It indicates that HWQT may help but not give complete disease control up till the retail and final consumption (Coates et al., 1993). So, there is need to include proper disease management procedures at pre and postharvest steps in order to address the problem of postharvest rots 4along the supply chains (Swart et al., 2009; Dessalegn et al., 2013; Alvindia and Acda, 2015; Scripong et al., 2015). In this study, Sportak (a.i. Prochloraz) was used @ 0.5 mL L-1 which is effective against anthracnose in mango; therefore, it could not control other body rots (SER and side rot). Hence, the role of new chemistry fungicides needs to be explored for effective disease control, better quality and shelf life.

Non-significant effects of treatments on most of the biochemical attributes both under low temperature storage (Table. 3 and 4) and ambient conditions (Table 1 and 2) indicate that the recently signed hot water phytosanitary protocols don’t have any negative impact on the internal fruit quality (Anwar and Malik, 2008) i.e. biochemical attributes of mango cv. Sufaid Chaunsa rather these protocols may enhance the value by improving fruit TSS/acid ratio (Table 4). Thus, there is potential of exporting mango cv. Sufaid Chaunsa (both by air and sea) after subjecting to the respective hot water phytosanitary protocols.

Refrigerated shipping potential of mango cv. Sufaid Chaunsa

Low temperature storage of fruits has been known to increase the shelf life and help in shipping perishable commodities like mango to distant off-shore markets. Based upon the economic advantages of refrigerated container shipment by sea or land routes over air-freight (Malik et al., 2010) these studies were more targeted to investigate the low temperature storage potential of mango cv. Sufaid Chaunsa for refrigerated shipment to the intended markets. The fruits of mango cv. Sufaid Chaunsa subjected to refrigerated shipment (10 ± 1 °C; 80-85% RH) showed respiratory increase after 3 weeks (21 days) of transition (Fig. 4). The fruits attained ripe stage under storage at 10 ± 1 °C after 35 days, which were poor in quality with significantly more peel discoloration (Table 3), higher titratable acidity and lower TSS, TSS/acid ratio and sugar content (Table 4). Hence, it is evident that the ripening process commences with higher rate of respiration after 3 weeks of storage under reefer conditions (10 ± 1 °C; 80-85% RH), so maximum potential of cultivar for reefer shipping is 21 days with shelf life of 7 days. In order to attain more shipping potential, the advanced technologies need to be employed which can slow down the respiration process of fruits during postharvest handling and storage. The use of controlled atmosphere (CA) and ethylene scrubbing can be investigated. Our subsequent studies showed that the commodity suffers with under-skin browning and peel discoloration which needs to be addressed through proper production, harvest and postharvest practices. Moreover, in order to avoid the losses caused by disease development (Barkai-Golan, 2001; Narayanasam. 2006; Bally et al., 2009) at retail; proper disease management operations must be adopted. Fruit side rot seems to be the major challenge in this regard (Table 3).

CONCLUSION

These studies indicated that HWQT protocols 48 °C for 60 min and 45 °C for 75 min significantly increased physiological processes resulting in higher rate of respiration and more weight loss as compared to control. However, no negative impact of both HWQTs was observed on fruit quality both under simulated ambient/air-freight and refrigerated container shipment conditions. HW temperature was found physiologically more critical as compared to the duration of HW treatment. The fruits of mango cv. Sufaid Chaunsa were found to possess potential of shipping to offshore markets up to 21 days under reefer storage conditions (10 ± 1 °C; 80-85% RH) with post-shipment shelf life of one week along with better maintained fruit quality at retail, provided with better production, harvest and postharvest handling practices. Moreover, the quality is expected to be much better at neighbouring destinations (in case of refrigerated container shipments by sea or land routes). However, it is critical to control postharvest disease development via pre and postharvest strategies, using CA storage and ethylene scrubbing for long distant shipment, which needs further research.

ACKNOWLEDGEMENTS

We gratefully acknowledge the financial support of Australian Centre for International Agricultural Research (ACIAR) for these studies under Australia-Pak ASLP (Phase-II): Mango Value Chain Improvement Project.

REFERENCES

Alvindia, D.G. and Acda, M.A. 2015. Revisiting the efficacy of hot water treatment in managing anthracnose and stem-end rot diseases of mango cv. ‘Carabao’. Crop Protection, 67: 96-101. [Abstract/FREE full text, Google Scholar]

Amin, M., Malik, A.U., Mazhar, M.S., Din, I., Khalid, M.S. and Ahmad, S. 2008. Mango fruit desapping in relation to time of harvesting. Pakistan Journal of Botany, 40: 1587-1593. [Abstract/FREE full text, Google Scholar]

Anwar, R. and Malik, A.U. 2006. Effect of hot water treatment and storage duration on shelf life and quality of Pakistani mango (Mangifera indica L.) cv. Sindhri. In: Abstract book. 27th International Horticultural Congress and Exhibition, Seoul, Korea, p. 258. [Abstract/FREE full text, Google Scholar]

Anwar, R. and Malik, A.U. 2007. Hot water treatment affects ripening quality and storage life of mango (Mangifera indica L.). Pakistan Journal of Agricultural Sciences, 44: 304-311. [Abstract/FREE full text, Google Scholar]

Anwar, R. and Malik, A.U. 2008. Effect of hot water treatment on storage life and quality of mango (Mangifera indica L.). Acta Horticulturae, 768: 201-207. [Abstract/FREE full text, Google Scholar]

Armstrong, J.W. and Follett, P.A. 2007. Hot-water immersion quarantine treatment against Mediterranean fruit fly and Oriental fruit fly (Diptera: Tephritidae) eggs and larvae in litchi and longan fruit exported from Hawaii. Journal of Economic Entomology, 100: 1091-1097. [Abstract/FREE full text, Google Scholar]

Bally, I.S.E., Hofman, P.J., Irving, D.E., Coates, L.M. and Dann, E.K. 2009. The effects of nitrogen on postharvest disease in mango (Mangifera indica L. ‘Keitt’). Acta Horticulturae, 820: 365-370. [Abstract/FREE full text, Google Scholar]

Barkai-Golan, R. 2001. Postharvest Diseases of Fruits and Vegetables. Elsevier Science B.V., Amsterdam, The Netherlands. [Abstract/FREE full text, Google Scholar]

Coates, L.M., Johnson, G.I. and Cooke, A.W. 1993. Postharvest disease control in mangoes using high humidity hot air and fungicide treatmens. Annals of Applied Biology, 123: 441-448. [Abstract/FREE full text, Google Scholar]

Dessalegn, Y., Ayalew, A. and Woldetsadik. K. 2013. Integrating plant defense inducing chemical, inorganic salt and hot water treatments for the management of postharvest mango anthracnose. Postharvest Biology and Technology, 85: 83-88. [Abstract/FREE full text, Google Scholar]

Faheem, M., Saeed, S., Sajjad, A., Rehman, A. and Farooq, M. 2012. In search of the best hot water treatments for Sindhri and Chaunsa variety of mango. Pakistan Journal of Zoology, 44: 101-108. [Abstract/FREE full text, Google Scholar] FAOSTAT. 2017. Crops: download data. Food and Agriculture Organization of United Nations. Available at: http://www.fao.org/faostat/en/#data/QC. Accessed on 9th January 2020.

Follett, P.A. and Neven, L.G. 2006. Current trends in quarantine entomology. Annual Review of Entomology, 51: 359-385. [Abstract/FREE full text, Google Scholar]

Govender, L., Korsten, L. and Sivakumar, D. 2005. Semi-commercial evaluation of Bacillus licheniformis to control mango postharvest disease in South Africa. Postharvest Biology and Technology, 38: 57-65. [Abstract/FREE full text, Google Scholar]

Hameed, R., Malik, A.U., Imran, M., Khan, A.S. and Schoten, S. 2010. Effects of controlled atmosphere on storability, shelf life and quality of green slender chilies (Capsicum annuum L.). Acta Horticulturae, 876: 123-134. [Abstract/FREE full text, Google Scholar]

Hortwitz, W. 1960. Official and Tentative Methods of Analysis, 9th Ed. Association of the Official Agriculture Chemists. Washington, DC, pp. 320-341.

Jabbar, A., Malik, A.U., Saeed, M., Malik, O.H., Amin, M., Rajwana, I.A., Khan, A.S., Saleem, B.A., Pervez, M.A. and Ayub, M. 2011. Performance of hot water phyto-sanintary treated mangoes for intended export to Iran and China. International Journal of Agriculture and Biology, 13: 645-651. [Abstract/FREE full text, Google Scholar]

Jacobi, K.K. and Wong, L.S. 1991. The injuries and changes in ripening behaviour caused to Kensington mango by hot water treatment. Acta Horticulturae, 291: 372-378. [Abstract/FREE full text, Google Scholar]

Jacobi, K.K. and Wong, L.S. 1992. Quality of ‘Kensington’ mango (Mangifera indica Linn.) following hot water and vapour-heat treatments. Postharvest Biology and Technology, 1: 349-359. [Abstract/FREE full text, Google Scholar]

Jacobi, K.K., Macrae, E.A. and Hetherington, S.E. 2001a. Postharvest heat disinfestations treatments of mango fruit. Scientia Horticulturae, 89: 171-193. [Abstract/FREE full text, Google Scholar]

Jacobi, K.K., Macrae, E.A. and Hetherington, S.E. 2001b. Effect of fruit maturity on the response of ‘Kensington’ mango fruit to heat treatment. Australian Journal of Experimental Agriculture, 41: 793-803. [Abstract/FREE full text, Google Scholar]

Jordan, R.A. 1993. The disinfestations heat treatment process. Plant quarantine in Asia and the Pacific. A report of an Asian Productivity Organization Study Meeting, Taipei, Taiwan, March 17-26, 1992. [Abstract/FREE full text, Google Scholar]

Julius, H. 1999. Irradiated fruit: lack of feasibility. Available online with updates at: http://www.rag.org.au/modifiedfoods/fruit irradiation lack of feasibility.htm. Accessed on 9th January 2020.

Khan, A.S., Hussain, K., Shah, H.M.S., Malik, A.U., Anwar, R., Rehman, R.N.U. and Bakhsh, A. 2018. Cold storage influences postharvest chilling injury and quality of peach fruits. Journal of Horticultural Science and Technology, 1(1): 28-34. [Abstract/FREE full text, Google Scholar]

Le, T.N., Shiesh, C.C. and Lin, H.L. 2010. Effect of vapor heat and hot water treatments on disease incidence and quality of Taiwan native strain mango fruits. International Journal of Agriculture and Biology, 12: 673-678. [Abstract/FREE full text, Google Scholar]

Lizada, M.C.C., Agravante, J.U. and Brown, E.O. 1986. Factors affecting postharvest disease control in ‘Carabao’ mango subjected to hot water treatment. Philippine Journal of Crop Science, 11: 153-161. [Abstract/FREE full text, Google Scholar]

Malik, A.U. and Singh, Z. 2005. Pre-storage application of polyamines improves shelf life and fruit quality of mango. Journal of Horticultural Science and Biotechnology, 80: 363-369. [Abstract/FREE full text, Google Scholar]

Malik, A.U., Campbell, J., Hofman, P., Amin, M. and Collins, R. 2013. Current best practices guidelines for mango value chain management in Pakistan: concepts and definitions. Australia-Pakistan Agriculture Sector Linkages Program (ASLP-II), Mango Value Chain Improvement Project, Pakistan. [Abstract/FREE full text, Google Scholar]

Malik, A.U., Hafeez, O., Johnson, P., Campbell, J.A., Amin, M., Saeed, M., Mazhar, M.S., Schouten, S. and Javed, A. 2010. Toward developing a sea-freight supply chain for delivering Pakistani mangoes to European supermarket: a private-public sector model. Acta Horticulturae, 880: 83-89. [Abstract/FREE full text, Google Scholar]

Miller, W.R. and Mcdonald, R.E. 1991. Quality changes during storage and ripening of ‘Tommy Atkins’ mangoes treated with heated forced air. HortScience, 26: 395-397. [Abstract/FREE full text, Google Scholar]

Moy, J.H. 2005. Tropical fruit irradiation from research to commercial application. Proceedings of the International Symposium on New Frontier of Irradiated Food and Non-Food Products. 22-23 September 2005. KMUTT, Bangkok, Thailand, p. 8. [Abstract/FREE full text, Google Scholar]

Narayanasam, P. 2006. Postharvest Pathogens and Disease Management. John Wiley and Sons, Inc., Hoboken, New Jersey, USA. [Abstract/FREE full text, Google Scholar]

Nascimento, A.S., Malavasi, A., Morgante, J.S. and Duarte, A.L.A. 1992. Hot-water immersion treatment for mangoes infested with Anastrepha fraterculus, A. oblique, and Ceratitis capitata (Diptera: Tephritidae) in Brazil. Journal of Economic Entomology, 85: 456-460. [Abstract/FREE full text, Google Scholar]

Perini, M.A., Sin, I.N., Jara, A.M.R., Lobato, M.E.G., Civello, P.M. and Martínez, G.A. 2017. Hot water treatments performed in the base of the broccoli stem reduce postharvest senescence of broccoli (Brassica oleracea L. var. italica) heads stored at 20 °C. LWT – Food Science and Technology, 77: 314-322. [Abstract/FREE full text, Google Scholar]

Ponce-de-León, L., Muñoz, C., Pérez, L., Diaz-de-León, F., Kerbel, C., Pérez-Flores, L., Esparza, S., Bósquez, E. and Trinidad, M. 1997. Hot-water quarantine treatment and water-cooling of ‘Haden’ mangoes. Acta Horticulturae, 455: 786-796. [Abstract/FREE full text, Google Scholar]

Porat, R., Daus, A., Weiss, B., Cohen, L., Fallik, E. and Droby, S. 2000. Reduction of postharvest decay in organic citrus fruit by a short hot water brushing treatment. Postharvest Biology and Technology, 18: 151-157. [Abstract/FREE full text, Google Scholar]

Ruck, J.A. 1969. Chemical Methods for Analysis of Fruits and Vegetables. Research Station Summerland, Canada Department of Agriculture. Publication No. 1154. [Abstract/FREE full text, Google Scholar]

Russel, D.F. and Eisensmith, S.P. 1983. MSTAT-C. Crop and Soil Science Department, Michigan State University, East Lansing, Michigan, USA. [Abstract/FREE full text, Google Scholar]

Sharp, J.L. 1993. Quarantine treatments for major mango pests. Acta Horticulturae, 341: 407-414. [Abstract/FREE full text, Google Scholar]

Sharp, J.L. and Heather, N.W. 2002. Quarantine treatments for pests of tropical fruits. In: Penna, J.E., Sharp, J.L. and Wysoki, M. (eds.). Tropical Fruit Pests and Pollinators. CAB International, Wallingford, UK, pp. 391-406. [Abstract/FREE full text, Google Scholar]

Singh, S.P. and Saini, M.K. 2014. Postharvest vapour heat treatment as a phytosanitary measure influences the aroma volatiles profile of mango fruit. Food Chemistry, 167: 387-395. [Abstract/FREE full text, Google Scholar]

Sripong, K., Jitareerat, P., Tsuyumu, S., Uthairatanakij, A., Srilaong, V., Wongs-Aree, C., Ma, G., Zhang L. and Kato, M. 2015. Combined treatment with hot water and UV-C elicits disease resistance against anthracnose and improves the quality of harvested mangoes. Crop Protection, 77: 1-8. [Abstract/FREE full text, Google Scholar]

Steel, R.G.D., Torrie, J.H. and Dicky, D.A. 1997. Principles and Procedures of Statistics: A Biological Approach. 3rd Ed. McGraw Hill Book Co. Inc., New York. [Abstract/FREE full text, Google Scholar]

Swart, S.H., Serfontein, J.J., Swart, G. and Labuschagne, C. 2009. Chemical control of post-harvest diseases of mango: the effect of fludioxonil and prochloraz on soft brown rot, stem-end rot and anthracnose. Acta Horticulturae, 820, 503-510. [Abstract/FREE full text, Google Scholar]

Vilaplana, R., Hurtado, G. and Valencia-Chamorro, S. 2018. Hot water dips elicit disease resistance against anthracnose caused by Colletotrichum musae in organic bananas (Musa acuminata). LWT – Food Science and Technology, 95: 247-254. [Abstract/FREE full text, Google Scholar]

Yahia, M.Y. and Pedro-Campos, J. 2000. The effect of hot water treatment used for insect control on the ripening and quality of mango fruit. Acta Horticulturae, 509: 495-514. [Abstract/FREE full text, Google Scholar]

Fruit export, fruit quality, heat treatment, Mangifera indica, quarantine treatment.

* Corresponding author

a Department of Horticulture, Muhammad Nawaz Shareef University of Agriculture, Multan, Pakistan

b Institute of Horticultural Sciences, University of Agriculture, Faisalabad, Pakistan

c Mango Research Station, Shujabad, Pakistan

Email: m.amin@mnsuam.edu.pk (M. Amin)

This article does not contain any abbreviations to display here.

Received: 21 March 2020

Revised: 18 April 2020

Accepted: 20 April 2020

Published: 30 April 2020

How to Cite

| AMA |

Amin M, Malik AU, Rajwana IA, et al. Postharvest respiration rate, physiological weight loss and physico-chemical quality of mango fruit as influenced by different hot water quarantine treatments under simulated shipment conditions. J Hortic Sci Technol. 2020;3(1):12-18. doi:https://doi.org/10.46653/jhst20030112

It also stocks cipla generic cialis T-shirts for men and women. A viagra in canada sex therapist helps to increase knowledge of sexual dysfunction and a lot more. Ladies may viagra canada pharmacies characterize sexual arousal in light of mental and enthusiastic, and in addition natural variables. In general, erectile dysfunction targets a man when he passes through the age between 40 and 60 and the chances becomes extremely after viagra pills price crossing sixties. |

| MLA |

Amin, Muhammad, et al. “Postharvest Respiration Rate, Physiological Weight Loss and Physico-Chemical Quality of Mango Fruit as Influenced by Different Hot Water Quarantine Treatments under Simulated Shipment Conditions.” Journal of Horticultural Science & Technology, vol. 3, no. 1, 2020, pp. 12–18, doi:https://doi.org/10.46653/jhst20030112.

|

| APA |

Amin, M., Malik, A. U., Rajwana, I. A., Razzaq, K., Faried, H. N., Ullah, S., Akhtar, G., Khan, A. S., Anwar, R., & Zafar, M. S. (2020). Postharvest respiration rate, physiological weight loss and physico-chemical quality of mango fruit as influenced by different hot water quarantine treatments under simulated shipment conditions. Journal of Horticultural Science & Technology, 3(1), 12–18. https://doi.org/10.46653/jhst20030112

|

Download Citation (RIGHT CLICK & “SAVE LINK AS”)

This article do not contain any supplementary data.