Abstract—

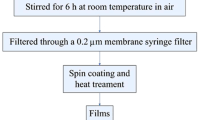

Some issues, such as leakage and tunneling currents, and light atom penetration through a thin gate dielectric, are threatening for silicon dioxide to be used as a suitable gate dielectric material for the next-generation metal-insulator-semiconductor-field-effect-transistor (MISFET) devices. A novel gate dielectric material for MISFET has been synthesized via the Pechini method by combining graphene oxide (GO)/dicalcium silicate (C2S) components. First, GO nanoparticles were synthesized via the Hummer method and C2S—via the Pechini method and then 0.1, 0.2, 0.4 and 0.8 the weight percentages (wt %) of GO were added into the C2S matrix. Their nanostructural properties were studied by the field emission scanning electron microscopy X-ray diffraction, Fourier transform infrared, thermo-gravimetry and differential scanning calorimetry. The electrical properties of GO/C2S nanocomposites, metal (Al)-GO/C2S insulator-Si (semiconductor) were fabricated by the physical vapor deposition technique at 10–7 Torr. The capacity, current-voltage relationship, quality factor, dissipation factor were measured with an LCR meter GPS-132A and 4-probe techniques. The frequency response of dielectric properties, dielectric constant, dielectric loss, and AC electrical conductivity, of the examined samples were studied. The electrical measurements showed that a sample with 0.4 wt % of GO nanoparticles has a higher dielectric constant at a frequency of 120 kHz (K = 62) and 1 kHz (K = 30), a lower leakage current (20 × 10–6 A/cm2), a good carrier mobility (7.62 cm2/V s), a low threshold voltage (2.9 V), a large current ION/IOFF ratio (1.25 × 103), and a higher quality factor (32.4). Therefore, C2S/GO nanocomposite with 0.4 wt % Go nanoparticles can be introduced as an alternative gate dielectric material for the next generation of MISFET devices.

Similar content being viewed by others

REFERENCES

Nishid, E., Miyaji, H., Kato, A., Takita, H., et al., Int. J. Nanomed., 2016, vol. 24, pp. 2265–2277.

Wang, H., Chen, Y., and Wei, Y., RCS Adv., 2016, vol. 41, pp. 34770–34781.

Bahari, A. and Shahbazi, M., J. Electron. Mater., 2016, vol. 45, pp. 1201–1209.

Zhao, W. and Chang, J., Mater. Sci. Eng., C, 2008, vol. 28, pp. 289–292.

Björnström, J., Martinelli, A., Matic, A., Börjesson, L., et al., Chem. Phys. Lett., 2004, vol. 392, pp. 242–248.

Hummers, W.S. and Offeman, R.E., J. Am. Chem. Soc., 1958, vol. 80, pp. 1339–1339.

Wang, H., Chen, Y., and Wei, Y., RSC Adv., 2016, vol. 6, pp. 34770–34781.

Shang, Y., Zhang, D., Yang, C., Liu, Y., et al., Constr. Build. Mater., 2015, vol. 96, pp. 20–28.

Lysenkov, E.A., Klepko, V.V., and Yakovlev, Yu.V., Surf. Eng. Appl. Electrochem., 2016, vol. 52, pp. 186–192.

Ghaharpour, F., Bahari, A., Abbasi, M., and Ashkaran, A.A., Constr. Build. Mater., 2016, vol. 113, pp. 523–535.

Bargui, M., Messaoud, M., and Elleuch, K., Surf. Eng. Appl. Electrochem., 2017, vol. 53, pp. 467–474.

Dastan, D. and Banpurkar, A., J. Mater. Sci., 2016, vol. 28, no. 4, pp. 3851–3859.

Shahbazi, M., Bahari, A., and Ghademi, Sh., Org. Electron., 2016, vol. 32, pp. 100–108.

Dastan, D., Panahi, S.L., and Chaure, N.B., J. Mater. Sci., 2016, vol. 27, no. 12, pp. 12 291–12 296.

Dastan, D., Chaure, N.B., and Kartha, M., J. Mater. Sci., 2017, vol. 28, no. 11, pp. 7784–7796.

Hoseinzadeh, S., Ghasemiasl, R., Bahari, A., and Ramezani, A.H., J. Mater. Sci. Mater. Electron., 2017, vol. 28, pp. 14 855–14 863.

Wang, J., Wu, J., Xu, W., Zhang, Q., et al., Compos. Sci. Technol., 2014, vol. 91, pp. 1–7.

Bahari, A., Babaeipour, M., and Soltani, B., J. Mater. Sci. Mater. Electron., 2016, vol. 27, pp. 2131–2137.

Bargui, M., Elleuch, K., Wery, M., and Ayedi, H.F., Surf. Eng. Appl. Electrochem., 2017, vol. 53, pp. 371–382.

Fortunato, E., Barquinha, P., and Martins, R., Adv. Mater., 2012, vol. 24, pp. 2945–2986.

Manan, A. and Hussain, I., Int. J. Mod. Phys. B, 2014, vol. 28, no. 15, pp. 1 450 092–1 450 098.

Hayati, A. and Bahari, A., Indian J. Phys., 2015, vol. 89, pp. 45–54.

Morales-Acosta, M.D., Quevedo-López, M.A., and Ramírez-Bon, R., J. Non-Cryst. Solids, 2013, vol. 362, pp. 124–135.

Morales-Acosta, M.D., Quevedo-López, M.A., and Ramírez-Bon, R., Mater. Chem. Phys., 2014, vol. 146, pp. 380–388.

Lee, S., Koo, B., Shin, J., Lee, E., et al., Appl. Phys. Lett., 2006, vol. 88, p. 162 109.

Deng, L.J., Gu, Y.Z., Xu, W.X. and Ma, Zh.Y., Chin. J. Chem. Phys., 2014, vol. 27, pp. 321–326.

Jonscher, A.K., Nature, 1977, vol. 267, pp. 673–679.

Frunză, R.C., Kmet, B., Jankovec, M., Topič M., et al., Mater. Res. Bull., 2014, vol. 50, pp. 323–328.

Selçuk, A.B., Ocak, S.B., Aras, G., and Orhan, E., Mater. Sci. Semicond. Process., 2015, vol. 38, pp. 119–125.

Gundlach, D.J., Lin, Y.Y., Jackson, T.N. and Schlom, D.G., Appl. Phys. Lett., 1997, vol. 71, no. 26, pp. 38–53.

Bahari, A., Roodbari Shahmiri, M., Derakhshi, M., and Jamali, M., J. Nanostruct., 2012, vol. 2, pp. 313–318.

Muñoz, J.R., Rivera, M.A.C., Munoz, J.L.F., Torres, M.Z., et al., Bull. Mater. Sci., 2017, vol. 40, no. 5, pp. 1043–1047.

Miao, Q., Adv. Mater., 2014, vol. 26, no. 31, pp. 5541–5549.

Naik, B.R., Avis, C., Chowdhury, M.D.H., Kim, T., et al., Jpn. J. Appl. Phys., 2016, vol. 55, no. 351, pp. 3413–3419.

Ting, G.G., Acton, O., Ma, H., Won Ka, J., et al., Langumir, 2009, vol. 25, pp. 2140–2147.

Miao, Q.I.A.N., Lefenfeld, M., Nguyen, T.Q., Siegrist, T., et al., Adv. Mater., 2011, vol. 23, no. 13, pp. 1535–1538.

Mushrush, M., Facchetti, A., Lefenfeld, M., Katz, H.E., et al., J. Am. Chem. Soc., 2003, vol. 125, no. 31, pp. 9414–9423.

Facchetti, A., Yoon, M.H., Stern, C.L., Hutchison, G.R., et al., J. Am. Chem. Soc., 2004, vol. 126, no. 41, pp. 13 480–13 501.

Xu, X., Cui, Q., Jin, Y., and Guo, X., Appl. Phys. Lett., 2012, vol. 101, p. 222 114.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Hussein Salmani, Ali Bahari GO/C2S Gate Dielectric Material for Nanoscale Devices Obtained via Pechini Method. Surf. Engin. Appl.Electrochem. 55, 379–389 (2019). https://doi.org/10.3103/S1068375519040136

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375519040136