Abstract

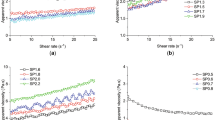

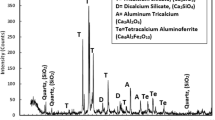

Cement asphalt emulsion (CA) composite materials are becoming promising building materials in recent years. Assessing their rheological behavior is crucial for the success of a particular application. Fresh CA pastes with different asphalt emulsion to cement mass ratios (AE/C) have significantly different compositions, and design of their rheological properties is not an easy task. The minimum apparent viscosity of CA pastes with different AE/C is predicted by a viscosity prediction model. The model parameters include maximum particle packing density (ϕ m) and an adjusting factor b. A predictive model of CA composite particles is proposed, in which the maximum particle packing density of CA pastes can be determined by the maximum particle packing density of cement paste, the maximum particle packing density of asphalt emulsion, and the volume fraction of asphalt in asphalt-cement system. The predictive model requires different adjusting factor b for CA pastes with anionic and cationic asphalt emulsion when the predicted ϕ m is used for viscosity prediction. The proposed viscosity prediction equations do offer a simple and reliable method for the viscosity prediction of CA pastes with a wide AE/C range, and can be used to design the rheological properties of CA pastes.

Similar content being viewed by others

References

Schmidt RJ, Santucci LE, Coyne LD (1973) Performance characteristics of cement modified asphalt emulsion mixes. Proc AAPT 42:300–319

Brown S, Needham D (2000) A study of cement modified bitumen emulsion mixtures. Proc AAPT 69:92–121

Bocci M, Grilli A, Cardone F et al (2011) A study on the mechanical behaviour of cement–bitumen treated materials. Constr Build Mater 25(2):773–778

Oruc S, Celik F, Akpinar MV (2006) Effect of cement on emulsified asphalt mixtures. J Mater Eng Perform 16(5):578–583

Li G, Zhao Y, Pang S et al (1998) Experimental study of cement–asphalt emulsion composite. Cem Concr Res 28(5):635–641

Song H, Do J, Soh Y (2006) Feasibility study of asphalt-modified mortars using asphalt emulsion. Constr Build Mater 20(5):332–337

Tan Y, Ouyang J, Lv J et al (2013) Effect of emulsifier on cement hydration in cement asphalt mortar. Constr Build Mater 47:159–164

Ouyang J, Tan Y, Li Y et al (2015) Demulsification process of asphalt emulsion in fresh cement-asphalt emulsion paste. Mater Struct 48(12):3875–3883

Rutherford T, Wang Z, Shu X et al (2014) Laboratory investigation into mechanical properties of cement emulsified asphalt mortar. Constr Build Mater 65:76–83

Bouveta A, Ghorbela E, Bennacer R (2010) The mini-conical slump flow test: analysis and numerical study. Cem Concr Res 40(10):1517–1523

Cremonesi M, Ferrara L, Frangi A et al (2010) Simulation of the flow of fresh cement suspensions by a Lagrangian finite element approach. J Non-Newton Fluid 165(23–24):1555–1563

Ferrara L, Cremonesi M, Tregger N, Frangi A, Shah SP (2012) On the identification of rheological properties of cement suspensions: rheometry, computational fluid dynamics modeling and field test measurements. Cem Concr Res 42(8):1134–1146

Saak AW, Jennings HM, Shah SP (2001) New methodology for designing self-compacting concrete. ACI Mater J 98(6):429–439

Roussel N (2006) A theoretical frame to study stability of fresh concrete. RILEM Mater Struct 39(1):75–83

Tregger N, Gregori A, Ferrara L, Shah SP (2012) Correlating dynamic segregation of self-consolidating concrete to the slump-flow test. Constr Build Mater 28(1):499–505

Kong X, Liu Y, Zhang Y et al (2014) Influences of temperature on mechanical properties of cement asphalt mortars. Mater Struct 47(1–2):285–292

Tan Y, Ouyang J, Li Y (2014) Factors influencing rheological properties of fresh cement asphalt emulsion paste. Constr Build Mater 68:611–617

Peng J, Deng D, Yuan Q et al (2014) Study of the rheological behavior of fresh cement emulsified asphalt paste. Constr Build Mater 66(15):348–355

Hu S, Wang T, Wang F et al (2009) Adsorption behaviour between cement and asphalt emulsion in CA mortar. Adv Cem Res 21:11–14

Zhang Y, Kong X, Hou S (2012) Study on the rheological properties of fresh cement asphalt paste. Constr Build Mater 27(1):534–544

Chong JS, Christiansen EB, Baer AD (1971) Rheology of concentrated suspensions. J Appl Polym Sci 15(8):2007–2021

Liu D (2000) Particle packing and rheological property of highly-concentrated ceramic suspensions: ϕ m determination and viscosity prediction. J Mater Sci 35:5503–5507

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology. Elsevier, Amsterdam

Krieger IM, Dougherty TJ (1959) A mechanism for non-Newtonian flow in suspensions of rigid spheres. J Rheol 3(1):137–152

Liu D (2002) Theoretical determination of floc size in highly-concentrated zirconia-wax suspensions. Acta Mater 39(14):3121–3137

Soua Z, Larue O, Vorobiev E et al (2006) Estimation of floc size in highly concentrated calcium carbonate suspension obtained by filtration with dispersant. Colloid Surf A 274(1–3):1–10

Phan TH, Chaouche M, Moranville M (2006) Influence of organic admixtures on the rheological behaviour of cement pastes. Cem Concr Res 36(10):1807–1813

Barnes HA (1989) Shear-thickening ‘dilatancy’ in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol 33:329–366

Tregger NA, Pakula ME, Shah SP (2010) Influence of clays on the rheology of cement pastes. Cem Concr Res 40(3):384–391

Acknowledgments

The first author acknowledges the support of China Scholarship Council and the fundamental research fund from Dalian University of Technology [DUT15RC(3)083].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ouyang, J., Tan, Y., Corr, D.J. et al. Viscosity prediction of fresh cement asphalt emulsion pastes. Mater Struct 50, 59 (2017). https://doi.org/10.1617/s11527-016-0897-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-016-0897-2