Abstract

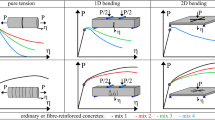

Experimental identification of the tensile constitutive behaviour of fibre reinforced cementitious composites represents a foremost step in design approaches for structural elements made with this kind of advanced construction materials. To this purpose, international standards and guidelines recommend either direct tension or/and bending tests, coupled with an inverse analysis procedure, both featuring pros and cons which have been exhaustively highlighted and discussed in these last years. The tremendous developments of self compacting fibre reinforced concretes have furthermore highlighted the need of duly taking into account, within the aforementioned identification procedure, the likely flow-induced alignment of fibres with the applied tensile stress. In this paper a novel experimental testing technique, called double edge wedge splitting test, has been presented and validated, also by means of nonlinear finite element analysis. The test, as it will be shown, is able to yield directly, i.e. with no need for back analysis, the tensile stress versus crack opening “constitutive relationship” of the material, though performing an “indirect” test, i.e. by applying a compressive load to the specimen. Both the simplicity of the indirect tensile testing technique and the straightforwardness of the identification procedure surely represent a distinctive and extremely attractive characteristic of the proposed test. Furthermore, the test features a compact specimen geometry, which can be even easily “cored” from existing structures, and a “notch preordained” fracture plane, which can be aligned to any desired angle with respect to the expected flow-induced fibre orientation. This makes the proposed test suitable for a thorough characterization of the influence of fibre orientation on the material constitutive behaviour, as it may be required by a casting process tailored to the intended applications.

Similar content being viewed by others

References

Ferrara L, Ozyurt N, di Prisco M (2011) High mechanical performance of fiber reinforced cementitious composites: the role of “casting-flow” induced fiber orientation. Mater Struct 44(1):109–128

Vicenzino E, Culham G, Perry VH, Zakariasen D, Chow TS (2005) First use of UHPFRC in thin precast concrete roof shell for Canadian LRT station. PCI J 50–67

Naaman AE, Fischer G, Krstulovic-Opara N (2007) Measurement of tensile properties of fiber reinforced concrete: draft submitted to ACI Committee 544. In: Naaman A, Reinhardt HW (eds) Proceedings of the 5th international RILEM workshop on high performance fiber reinforced cement composites, HPFRCC5, Mainz (Germany), July 13–15, RILEM Pubs, PRO 53, pp 3–12

Mechtcherine V (2007) Testing behaviour of strain hardening cement-based composites in tension—summary of recent research. In: Naaman A, Reinhardt HW (eds) Proceedings of the 5th international RILEM workshop on high performance fiber reinforced cement composites, HPFRCC5, Mainz (Germany), July 13–15 2007, RILEM Pubs, PRO 53, pp 13–122

SETRA (2002) Bétons fibrés à ultra-haute performances (2002)—ultra high performance fiber-reinforced concretes (in French and English)

CNR-DT 204 (2006) Guidelines for the design, manufacturing and control of SFRC structures (in Italian)

JSCE (2007) M recommendations for design and construction of high performance fiber reinforced cement composites with multiple fine cracks (HPFRCC). JSCE Conc Libr 127:129–135

di Prisco M, Plizzari G, Vandewalle L (2009) Fiber reinforced concrete. New design perspectives. Mater Struct 42(9):1261–1281

Soranakom C, Mobasher B (2008) Correlation of tensile and flexural responses of strain softening and strain hardening cement composites. Cem Concr Compos 30:465–477

Soranakom C, Mobasher B (2009) Flexural design of fiber reinforced concrete. ACI Mater J 106(5):461–469

Naaman AE, Reinhardt HW (2006) Proposed classification of HPFRC composites based on their tensile response. Mater Struct 39(5):547–555

Molins C, Aguado A, Saludes S (2009) Double punch test to control the energy dissipation in tension of FRC (Barcelona test). Mater Struct 42:415–425

Bruhwiler E, Wittman FH (1990) The wedge splitting test: a new method of performing stable fracture mechanics tests. Eng Fract Mech 35(1–3):117–125

Mechtcherine V, Müller HS (1998) Effect of the test set-up on fracture mechanical parameters of concrete. In: Mihashi H, Rokugo K (eds) Fracture mechanics of concrete structures, Proceedings FraMCoS-3, Gifu (Japan), Aedificatio, pp 377–386

di Prisco M, Felicetti R, Iorio F (2000) FRHPC precast roof elements: from constitutive to structural behaviour in bending. In: Chanvillard J, Rossi P (eds) Fibre reinforced concretes, proceedings of the 5th international RILEM symposium on FRC, BEFIB 2000, Lyon, France, September 13–15, 2000, RILEM Pubs, pp 233–243

Denneman E, Kearsley EP, Visser AT (2011) Splitting tensile test for fibre reinforced concrete. Mater Struct 44:1441–1449

di Prisco M, Lamperti MGL, Lapolla S, Khurana RS (2008) HPFRCC thin plates for precast roofing. In: Proceedings 2nd international symposium on HPC, Kassel, pp 675–682

Ferrara L, Faifer M, Toscani S (2012) A magnetic method for non destructive monitoring of fiber dispersion and orientation in steel fiber reinforced cementitious composites—part 1: method calibration. Mater Struct 45(4):575–589

Ferrara L, Faifer M, Muhaxheri M, Toscani S (2012) A magnetic method for non destructive monitoring of fiber dispersion and orientation in steel fiber reinforced cementitious composites—part 2: correlation to tensile fracture toughness. Mater Struct 45(4):591–598

di Prisco M, Mazars J (1996) Crush-crack: a non-local damage model for concrete. J Mech Cohes Frict Mater 1(1996):321–347

Ferrara L, di Prisco M (2001) Mode I fracture behavior in concrete: non-local damage modelling. ASCE J Eng Mech 127(7):678–692

Le Fichoux E (2011) Utilizer Cast3M. Presentation et utilization de Cast3M. http://www-cast3m.cea.fr/html/Documentation_Cast3M/Presentation_Cast3M.pdf. Accessed 22 Jan 2013 (in French)

Carmona S, Aguado A (2012) New model for the indirect determination of the tensile stress–strain curve of concrete by means of the Brazilian test. Mater Struc 45(10):1473–1485

Boulekbache B, Hamrat M, Chemrouk M, Amziane S (2010) Flowability of fibre-reinforced concrete and its effect on the mechanical properties of the material. Constr Build Mater 24:1664–1671

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

di Prisco, M., Ferrara, L. & Lamperti, M.G.L. Double edge wedge splitting (DEWS): an indirect tension test to identify post-cracking behaviour of fibre reinforced cementitious composites. Mater Struct 46, 1893–1918 (2013). https://doi.org/10.1617/s11527-013-0028-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0028-2