Abstract

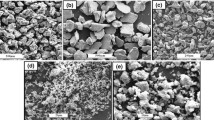

For thixoforming, it is necessary to have a good microstructure of fine, uniform, and globular grains in a semisolid range. In this study, the nano-Al2O3(Al2O3np)/Al7075 composites with a high solid fraction were fabricated by specially made Al2O3np containing Mg powders and semisolid ultrasonic vibration (SSUV) process. The influence of SSUV technology on primary α-Al grain and second phase in the composites was investigated. Microstructural studies revealed that a good semisolid slurry with an average grain size of 73 μm, a shape factor of 0.84, and a solid fraction of 0.715 could be obtained. Also, it could be shown that SSUV affected largely the size and type of the second phase as well as growth and nucleation of the primary α-Al grain. TEM analysis revealed that there are well-defined crystallographic orientation relationships between the second phases and α-Al, suggesting enhanced heterogeneous nucleation in Al7075 alloys. Moreover, mechanisms involved in the development of microstructure were discussed.

Similar content being viewed by others

References

H. Su, W.L. Gao, Z.H. Feng, and Z. Lu: Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Des. 36, 590–596 (2012).

A.J. Knowles, X. Jiang, M. Galano, and F. Audebert: Microstructure and mechanical properties of 6061 Al alloy based composites with SiC nanoparticles. J. Alloys Compd. 615, S401–S405 (2014).

S.J. Huang, W.Y. Peng, B. Visic, and A. Zak: Al alloy metal matrix composites reinforced by WS2 inorganic nanomaterials. Mater. Sci. Eng., A 709, 290–300 (2018).

X.H. Chen and H. Yan: Constitutive behavior of Al2O3np/Al7075 composites with a high solid fraction for thixoforming. J. Alloys Compd. 708, 751–762 (2017).

Q. Tang, M.Y. Zhou, L.L. Fan, Y.W.X. Zhang, G.F. Quan, and B. Liu: Constitutive behavior of AZ80M magnesium alloy compressed at elevated temperature and containing a small fraction of liquid. Vacuum 155, 476–489 (2018).

Y. Birol: Thixoforming of EN AW-2014 alloy at high solid fraction. J. Mater. Process. Technol. 211, 1749–1756 (2011).

A. Bolouri, M. Shahmiri, and C.G. Kang: Study on the effects of the compression ratio and mushy zone heating on the thixotropic microstructure of AA7075 aluminum alloy via SIMA process. J. Alloys Compd. 509, 402–408 (2011).

M.R. Rokni, Z. Zarei-Hanzaki, H.R. Abedi, and N. Haghdadi: Microstructure, evolution, and mechanical properties of backwark thixoextruded 7075 aluminum alloy. Mater. Des. 36, 557–563 (2012).

G.I. Eskin: Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys. Ultrason. Sonochem. 8, 319–325 (2001).

S.S. Wu, S.L. Lü, P. An, and H. Nakae: Microstructure and property of rheocasting aluminum-alloy made with indirect ultrasonic vibration process. Mater. Lett. 73, 150–153 (2012).

C. Lin, S.S. Wu, S.L. Lü, P. An, and L. Wan: Microstructure and mechanical properties of rheo-diecast hypereutectic Al–Si alloy with 2% Fe assisted with ultrasonic vibration process. J. Alloys Compd. 568, 42–48 (2013).

H. Yan, Y.S. Rao, and R. He: Morphological evolution of semi-solid Mg2Si/AM60 magnesiummatrix composite produced by ultrasonic vibration process. J. Mater. Process. Technol. 214, 612–619 (2014).

Q.M. Liu, Q.J. Zhai, F.P. Qi, and Y. Zhang: Effects of power ultrasonic treatment on microstructure and mechanical properties of T10 steel. Mater. Lett. 61, 2422–2425 (2007).

N. Iqbal, N.H.V. Dijk, S.E. Offerman, M.P. Moret, L. Katgerman, and G.J. Kearley: Nucleation kinetics during the solidification of aluminum alloys. J. Non-Cryst. Solids 353, 3640–3643 (2007).

X.H. Chen and H. Yan: Fabrication of nanosized Al2O3 reinforced aluminum matrix composites by subtype multifrequency ultrasonic vibration. J. Mater. Res. 30, 2198–2209 (2015).

F. Taghavi, H. Saghafian, and Y.H.K. Kharrazi: Study on the effect of prolonged mechanical vibration on the grain refinement and density of A356 aluminum alloy. Mater. Des. 30, 1604–1611 (2009).

C. Sauter, M.A. Emin, H.P. Schuchmann, and S. Tavman: Influence of hydrostatic pressure and sound amplitude on the ultrasound induced dispersion and de-agglomeration of nanoparticles. Ultrason. Sonochem. 15, 517–523 (2008).

Z.W. Liu, Q.Y. Han, J.G. Li, and W.D. Huang: Effect of ultrasonic vibration on microstructural evolution of the reinforcements and degassing of in situ TiB2p/Al–12Si–4Cu composites. J. Mater. Process. Technol. 212, 365–371 (2012).

R.D. Doherty, H.I. Lee, and E.A. Feest: Microstructure of stir-cast metals. Mater. Sci. Eng. 65, 181–189 (1984).

R. Chaim: Grain coalescence by grain rotation in nano-ceramics. Scr. Mater. 66, 269–271 (2012).

A. Bolouri, M. Shahmiri, and E.N.H. Cheshemeh: Microstructural evolution during semisolid state strain induced melt activation process of aluminum 7075 alloy. Trans. Nonferrous Met. Soc. China 20, 1663–1671 (2010).

E.D. Manson-Whitton, I.C. Stone, J.R. Jones, P.S. Grant, and B. Cantor: Isothermal grain coarsening of spray formed alloys in the semi-solid state. Acta Mater. 50, 2517–2535 (2002).

B.F. Schultz, J.B. Ferguson, and P.K. Rohatgi: Microstructure and hardness of Al2O3 nanoparticle reinforced Al–Mg composites fabricated by reactive wetting and stir mixing. Mater. Sci. Eng., A 530, 87–97 (2011).

J. Dong, J.Z. Cui, Q.C. Le, and Q.M. Lu: Liquidus semi-continuous casting, reheating and thixoforming of a wrought aluminum alloy 7075. Mater. Sci. Eng., A 345, 234–243 (2003).

D. Liu, H.V. Atkinson, P. Kapranos, W. Jirattiticharoean, and H. Jones: Microstructural evolution and tensile mechanical properties of thixoformed high performance aluminium alloy. Mater. Sci. Eng., A 361, 213–224 (2003).

H. Zhang and J.N. Wan: Thixoforming of spray-formed 6066 Al/SiCP composites. Compos. Sci. Technol. 61, 1233–1238 (2011).

Q.D. Qin, Y.G. Zhao, P.J. Cong, W. Zhou, and B. Xu: Semisolid microstructure of Mg2Si/Al composites by cooling slope cast and its evolution during partial remelting process. Mater. Sci. Eng., A 444, 99–103 (2007).

D.H. Kirkwood: Semisolid metal processing. Int. Mater. Rev. 39, 173–189 (1994).

S. Ashouri, M. Nili-Ahmadabadi, M. Moradi, and M. Iranpour: Semi-solid microstructure evolution during reheating of aluminum A356 alloy deformed severely by ECAP. J. Alloys Compd. 466, 67–72 (2008).

J.F. Jiang, Y. Wang, and H.V. Atkinson: Microstructural coarsening of 7005 aluminum alloy semisolid billets with high solid fraction. Mater. Charact. 90, 52–61 (2014).

S. Ji, Z. Fan, and M.J. Bevis: Semi-solid processing of engineering alloys by a twin-screw rheomoulding process. Mater. Sci. Eng., A 299, 210–217 (2001).

X.G. Fan, D.M. Jiang, Q.C. Meng, and L. Zhong: The microstructural evolution of an Al–Zn–Mg–Cu alloy during homogenization. Mater. Lett. 60, 1475–1479 (2006).

Y. Du, Y.A. Chang, B.Y. Huang, W.P. Gong, Z.P. Jin, H.H. Xu, Z.H. Yuan, Y. Liu, Y.H. He, and F.Y. Xie: Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng., A 363, 140–151 (2003).

M. Johnsson and L. Eriksson: Thermal expansion of Al and TiB2 in the temperature range 300 to 900 K and calculated lattice fit at the melting temperature for Al. Z. Metallkd. 89, 478–480 (1998).

S. Sanjabi and A. Obeydavi: Synthesis and characterization of nanocrystalline MgAl2O4 spinel via modified sol–gel method. J. Alloys Compd. 645, 535–540 (2015).

G. Rosas, J. Reyes-Gasga, and R. Pérez: Morphological characteristics of the rapidly and conventionally solidified alloys of the AlCuFe system. Mater. Charact. 58, 765–770 (2007).

B.L. Bramfitt: The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1, 1–9 (1970).

ACKNOWLEDGMENTS

The authors express their gratitude to the National Science Foundation of China (51364035) and Science and Technology Program of Education Office of Jiangxi Province (GJJ171065) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, XH., Yan, H. Fabrication of Al7075–Al2O3np-based metal matrix composites with a high solid fraction for thixoforming. Journal of Materials Research 33, 4349–4361 (2018). https://doi.org/10.1557/jmr.2018.343

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.343