Abstract

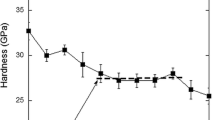

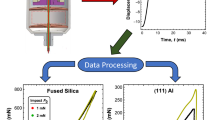

The ultra-low load indentation response of ceramic single crystal surfaces (Al2O3, SiC, Si) has been studied with a software-controlled hardness tester (Nanoindenter) operating in the load range 2–60 mN. In all cases, scanning and transmission electron microscopy have been used to characterize the deformation structures associated with these very small-scale hardness impressions. Emphasis has been placed on correlating the deformation behavior observed for particular indentations with irregularities in recorded load-displacement curves. For carefully annealed sapphire, a threshold load (for a given indenter) was observed below which the only surface response was elastic flexure and beyond which dislocation loop nucleation occurred at, or near, the theoretical shear strength to create the indentation. This onset of plasticity was seen as a sudden displacement discontinuity in the load-displacement response. At higher loads, indentations appeared to be accommodated predominantly by dislocation activity, though microcracks were observed to form ät contact loads of only tens of milliNewtons. Possibly such cracks are the incipient slip-induced nuclei for the much larger, indentation-induced cracks usually apparent only on the surface at much higher loads and often used for estimating indentation toughness. By contrast, silicon did not show this behavior but exhibited unusually large amounts of depth recovery within indentations, resulting in a characteristic reverse thrust on the indenter during unloading. TEM studies of indentations in silicon revealed less evidence of obvious dislocation activity than in sapphire (particularly at the lowest loads used) but did show residual highly imperfect–and often amorphous–structures within the indentations, consistent with a densification transformation occurring at the very high hydrostatic stresses produced under the indenter. The reverse thrust is caused by the relaxation of densified material during unloading. Thus, it appears that the low-load hardness response of silicon is controlled by a pressure-sensitive phase transformation. Though SiC has been predicted to undergo a densification transformation similar to silicon, its load-displacement behavior was found to be similar to Al2O3 suggesting that, for these contact experiments at least, the critical resolved shear stress for dislocation nucleation is exceeded before the critical hydrostatic pressure for densification is reached. In all cases, residual, plastically formed indentations were measured to be smaller than the fully loaded indentation depths would suggest, confirming that a significant portion of the deformation is elastic surface flexure. However, there is some doubt as to whether silicon displays elastic-only deformation even at very small penetration depths. The use of microstructural studies to complement nanoindentation experiments is shown to be a key route not only to interpreting the recorded load-displacement responses, but also to examining the deformation mechanisms controlling the mechanical behavior of ceramics to surface contacts at these small spatial scales.

Similar content being viewed by others

References

J. Pethica, R. Hutchings, and W. C. Oliver, Philos. Mag. A48, 593 (1983).

D. Newey, M. A. Wilkins, and H. M. Pollock, J. Phys. E 15, 119 (1982).

See, for example, H. Bückle, in The Science of Hardness Testing and its Research Applications, edited by J. H. Westbrook and H. Conrad (American Society for Metals, Metals Park, OH, 1973), pp. 453–494.

P. M. Sargent and T. F. Page, J. Mater. Sci. 20, 2388 (1985).

L. E. Samuels and T. O. Mulhearn, J. Mech. Phys. Solids 5, 125 (1957).

P. J. Burnett and T. F. Page, J. Mater. Sci. 19, 845 (1984).

Μ. F. Doerner and W. D. Nix, J. Mater. Res. 1, 601 (1986).

W. C. Oliver, C. J. McHargue, G. C. Farlow, and C. W. White, in Defect Properties and Processing of High-Technology Nonmetallic Materials, edited by J. H. Crawford, Jr., Y. Chen, and W. A. Sibley (Mater. Res. Soc. Symp. Proc. 24, Pittsburgh, PA, 1984), pp. 515–523.

W. C. Oliver and G. M. Pharr, in preparation (1991).

See, for example, P. J. Burnett and D. Rickerby, Surf. Eng. 3, 69 (1987) and J. C. Knight, T. F. Page, and I. M. Hutchings, Surf. Eng. 5, 213 (1989).

T. F. Page and J. C. Knight, Surf. Coat. Technol. 39/40, 339 (1989).

J. C. Knight, A. J. Whitehead, and T. F. Page, J. Mater. Sci. (1992, in press).

D. Marshall, T. Noma, and A. G. Evans, J. Am. Ceram. Soc. 65, C175 (1982).

M. G. S. Naylor and T. F. Page, J. Microscopy 130, 345 (1983).

J. Ν. Ness and Τ. F. Page, in Tailoring Multiphase and Composite Ceramics, edited by R. E. Tressler (Mater. Sci. Res. 20) (Plenum Press, New York, 1986), p. 347.

J. A. Yeomans and T. F. Page, J. Mater. Sci. 25, 2312 (1991).

Supplied by Professor P. Krishna, Banaras Hindu University, India.

Supplied by Dr. S. Pennycook, ORNL, Solid State Division.

T. F. Page, C. J. McHargue, and C. W. White, J. Microscopy 163, 245 (1991).

Courtesy ORNL Solid State (JEOL 840) and Electron Microscopy (EM 430) Divisions.

A. Fisher and P. Angelini, in Proc. 43rd Annual Meeting of Electron Microscopy Society of America, 1985, p. 182.

See, for example, A. Kelly, Strong Solids (Oxford University Press, United Kingdom, 1966), p. 66.

See, for example, N. Gane and J. M. Cox, Philos. Mag. 22, 881 (1970).

S. J. Bull, T. F. Page, and E. H. Yoffe, Philos. Mag. Lett. 59, 281 (1989).

L. M. Brown, unpublished work (1991).

See, for example, S. L. Lehoczky, J. Appl. Phys. 49, 5479 (1978).

See, for example, A. H. Cottrell, Dislocations and Plastic Flow in Crystals (Oxford University Press, United Kingdom, 1953), pp. 53–54; and J. P. Hirth and J. Lothe, Theory of Dislocations (McGraw-Hill, New York, 1968), pp. 688–689 and the references cited therein.

See, for example, B. J. Hockey and B. R. Lawn, J. Mater. Sci. 10, 1275 (1975).

B. R. Lawn and A. G. Evans, J. Mater. Sci. 12, 2195 (1977).

A. J. Whitehead, private communication (Newcastle Nanoindenter).

N. J. Hill and D. J. Rowcliffe, J. Mater. Sci. 9, 1569 (1984).

D. R. Clarke, M. C. Kroll, P. D. Kirchner, R. F. Cook, and B. J. Hockey, Phys. Res. Lett. 60, 2156 (1988).

See, for example, I. V. Gridneva, Yu V. Milman, and V. I. Trefilov, Phys. Status Solidi (a) 14, 177 (1972); and V. F. Eremenko and V. l. Nikitenko, Phys. Status Solidi (a) 44, 317 (1971), together with the references cited in (32) and (34).

G. R. Sawyer, P. M. Sargent, and T. F. Page, J. Mater. Sci. 15, 1001 (1980).

A. J. Whitehead and T. F. Page, J. Mater. Sci. (1992, to be submitted).

K. Brack, J. Appl. Phys. 36, 3560 (1965).

O. O. Adewoye and T. F. Page, J. Mater. Sci. 11, 981 (1976).

Ε. Μ. Onitsch, Microskopie 2, 345 (1947).

P. Μ. Sargent and Τ. F. Page, Proc. British Ceramic Society 26, 209 (1978).

See, for example, S. P. Timoshenko and J. N. Goodier, Theory of Elasticity (McGraw-Hill/Kogakusha, 1970), p. 413.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Page, T.F., Oliver, W.C. & McHargue, C.J. The deformation behavior of ceramic crystals subjected to very low load (nano)indentations. Journal of Materials Research 7, 450–473 (1992). https://doi.org/10.1557/JMR.1992.0450

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1992.0450