Abstract

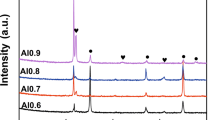

The authors investigated the effects of the isothermal heat-treatment conditions on the microstructural evolution and composition distribution of semisolid Al-4Cu-Mg alloy during isothermal heat treatment. The experimental results show that the microstructural evolution and composition distribution of semisolid Al-4Cu-Mg alloy are controlled by atom diffusion during the isothermal heat treatment process. Grain growth and spheroidization were promoted with the increase of the isothermal temperature and/or the holding time. Moreover, the higher the isothermal temperature, or the longer the holding time, the more segregation constituent elements occurred to the grain boundaries. The low melting structure at grain boundary is greatly affected by Cu. The microstructural evolution in the isothermal heat-treatment process is as follows: recovery, recrystallization, fragmentation, spheroidization, and coarsening. Such fragmentation, spheroidization, and grain growth of coalescence and Ostwald ripening are involved as main mechanisms in the isothermal heat-treatment process.

Similar content being viewed by others

References

M.C. Flemings: “Behavior of Metal Alloys in the Semisolid State,” Metall. Trans. A, 1991, 22, pp. 957–81.

D.H. Kirkwood: “Semisolid Metal Processing,” Int. Mater. Rev., 1994, 39, pp. 173–89.

M.P. Kenney, J.A. Courtois, R.D. Evans, G.M. Farrior, C.P. Kyonka, A.A. Koch, and K.P. Young: “Semi-Solid Metal Casting and Forging,” Casting, Vol. 15, ASM Handbook, ASM International, Materials Park, OH, 1988, pp. 327–38.

P. Kapranos, D.H. Kirkwood, and C.M. Sellars: “Thixoforming High Melting Point Alloys Into Non-metallic Dies,” in Proceedings of the 4th International Conference on the Semi-Solid Processing of Alloys and Composites, Sheffield, UK, 1996, pp. 306–11.

W. Lapkowski: “Some Studies Regarding Thixoforming of Metal Alloys,” J. Mater. Proc. Technol., 1998, 80–81, pp. 463–68.

A. Turkeli and N. Akbas: “Formation of Non-Dendritic Structure in 7075 Wrought Aluminum Alloy by SIMA Process and Effect of Heat Treatment” in Proceedings of the 4th International Conference on Semi-Solid Processing of Alloys and Composites, Sheffield, UK, 1996, pp. 71–74.

W.R. Loué and M. Suéry: “Microstructural Evolution During Partial Remelting of Al-Si7Mg Alloys,” Mater. Sci. Eng. A, 1995, 203, pp. 1–13.

H.Q. Hu: Solidification Technology, Metallurgical Industry, Beijing, China, 1985, pp. 60–62.

V.S. Solomatov, R. EI-Khozondar, and V. Tikare: “Grain Size in the Lower Mantle: Constraints from Numerical Modeling of Grain Growth in Two-phase Systems,” Phys. Earth Planet. Int., 2002, 129, pp. 265–82.

P.W. Iwashita and R.P. Wei: “Coarsening of Grain Boundary Carbides in a Nickel-based Ternary Alloy During Creep,” Acta Mater., 2000, 48, pp. 3145–56.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Haitao, J., Miaoquan, L. Effects of isothermal heat treatment on microstructural evolution of semisolid Al-4Cu-Mg alloy. J. of Materi Eng and Perform 13, 488–492 (2004). https://doi.org/10.1361/10599490420034

Received:

Issue Date:

DOI: https://doi.org/10.1361/10599490420034