Abstract

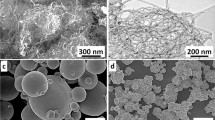

77 Ni–23 Ag nanocomposite powder as well as nanopowders of Ni and Ag were produced by electric explosion of wires, and compacted specimens were made with the help of a cold sintering method at a high pressure. It is shown that electric explosion results in formation of mainly janus-nanoparticles of immiscible Ni and Ag metals with retention of nanostructure in consolidated bulk specimens. Microstructure and mechanical properties of cold sintered specimens prepared from as prepared and heat treated in hydrogen flow have been studied. It is ascertained that treatment of 70% dense compacts in hydrogen flow results in higher density and higher ductility of cold sintered specimens. Density of cold sintered at 3 GPa pressure 77 Ni–23 Ag and Ni specimens was reached about 95% from theoretical value whereas the density of Ag specimens is close to 100% of that. High strength was obtained under three-point bending tests and in compression tests.

Similar content being viewed by others

REFERENCES

Lenel, F.V., Powder Metallurgy: Principles and Applications, Princeton, NJ: Metal Powder Ind. Fed., 1980.

Gutmanas, E.Y., Materials with fine microstructures by advanced powder metallurgy, Progr. Mater. Sci., 1990, vol. 34, pp. 261–366.

Gutmanas, E.Y., Cold-sintering—high pressure consolidation, in ASM Handbook, Vol. 7: Powder Metal Technologies and Applications, Materials Park, Oh: ASM Int., 1998, pp. 574–583.

Suryanarayana, C., Mechanical alloying and milling, Progr. Mater. Sci., 2001, vol. 46, pp. 1–184.

Ma, E., Alloys created between immiscible elements, Progr. Mater. Sci., 2005, vol. 50, pp. 413–509.

Herr, U., Ying, J., Gonser, U., and Gleiter, H., Alloy effects in consolidated binary mixtures of nanometer-sized crystals investigated by Mössbauer spectroscopy, Solid State Commun., 1990, vol. 76, pp. 197–202.

Gutmanas, E.Y., Trusov, L.K., and Gotman, I., Consolidation, microstructure and mechanical properties of nanocrystalline metal powders, Nanostruct. Mater., 1994, vol. 4, pp. 893–901.

Gutmanas, E.Y., Trudler, A., and Gotman, I., Processing and properties of dense Cu nanocomposites, Mater. Sci. Forum, 2002, vols. 386–388, pp. 329–334.

Karwan-Baczewska, J., Gotman, I., Gutmanas, E.Y., and Shapiro, M., Small particles with better contacts make nanocomposites kings of conductivity, Met. Powder Rep., 2005, vol. 60, no. 6, pp. 28–34.

Toshima, N. and Yonezawa, T., Bimetallic nanoparticles—novel materials for chemical and physical applications, New J. Chem., 1998, vol. 22, pp. 1179–1201.

Leslie-Pilecky, D.L. and Rieke, R.D., Magnetic properties of nanostructured materials, Chem. Mater., 1996, vol. 8, pp. 1770–1783.

Gutmanas, E.Y., Rabinkin, A., and Roitberg, M., Cold sintering under high pressure, Scr. Metall., 1979, vol. 13, pp. 11–15.

Gutmanas, E.Y., Cold sintering under high pressure—mechanisms and application, Powder Metall. Int., 1983, vol. 15, pp. 129–132.

Gutmanas, E.Y., Trusov, L.K., and Gotman, I., Consolidation, microstructure and mechanical properties of nanocrystalline metal powders, Nanostruct. Mater., 1994, vol. 4, pp. 893–901.

Gutmanas, E.Y., Trudler, A., and Gotman, I., Processing and properties of dense Cu nanocomposites, Mater. Sci. Forum, 2002, vols. 386–388, pp. 329–334.

Karwan-Baczewska, J., Gotman, I., Gutmanas, E.Y., and Shapiro, M., Small particles with better contacts make nanocomposites kings of conductivity, Met. Powder Rep., 2005, vol. 60, no. 6, pp. 28–34.

Lee, C.-C. and Chen, D.H., Large-scale synthesis of Ni–Ag core-shell nanoparticles with magnetic, optical and antioxidation properties, Nanotechnology, 2006, vol. 17, pp. 3094–3099.

Ishizaki, T., Yatsugi, K., and Akedo, K., Effect of particle size on the magnetic properties of Ni nanoparticles synthesized with trioctylphosphine as the capping agent, Nanomaterials, 2016, vol. 6, pp. 172–184.

Sharipova, A., Psakhie, S.G., Swain, S.K., Gotman, I., and Gutmanas, E.Y., High-strength bioresorbable Fe–Ag nanocomposite scaffolds: processing and properties, AIP Conf. Proc., 2015, vol. 1683, p. 020244.

Sharipova, A., Swain, S.K., Gotman, I., Starosvetsky, D., Psakhie, S.G., Unger, R., and Gutmanas, E.Y., Mechanical, degradation and drug-release behavior of nano-grained Fe–Ag composites for biomedical applications, J. Mech. Behav. Biomed. Mater., 2018, vol. 86, pp. 240–249.

Kotov, Yu.A., Electric explosion of wires as a method for preparation of nanopowders, J. Nanoparticle Res., 2003, vol. 5, pp. 539–550.

Lerner, M.I., Pervikov, A.V., Glazkova, E.A., Svarovskaya, N.V., Lozhkomoev, A.S., and Psakhie, S.G., Structures of binary metallic nanoparticles produced by electrical explosion of two wires from immiscible elements, Powder Technol., 2016, vol. 288, pp. 371–378.

Gleiter, H., Nanocrystalline materials, Progr. Mater. Sci., 1989, vol. 33, pp. 223–315.

Lerner, M.I., Psakhie, S.G., Lozhkomoev, A.S., Sharipova, A.F., Pervikov, A.V., Gotman, I., and Gutmanas, E.Y., Fe–Cu nanocomposites by high pressure consolidation of powders prepared by electric explosion of wires, Adv. Eng. Mater., 2018, vol. 20, no. 7, p. 1701024. https://doi.org/10.1002/adem.201701024.

Lin, S.-H., Chen, S.-Y., Chen, Y.-T., and Cheng, S.-Y., Electrochemical fabrication and magnetic properties of highly ordered silver-nickel core-shell nanowires, J. Alloys Compd., 2008, vol. 449, pp. 232–236.

Wang, L., Wang, W., Wang, Y., Wang, T., Zhou, S., Hu, L., Liu, T., Elfalleh, W., and Yu, D., Structural characteristics of Ni–Ag magnetic catalyst and its properties in soybean oil hydrogenation, Food Bioprod. Process., 2018, vol. 109, pp. 139–147.

Ger, T.-R., Huang, H.-T., Huang, C.-Y., Liu, W.-C., Lai, T.-Y., Liu, B.-T., Chen, J.-Y., Hong, C.-W., Chen, P.-J., and Lai, M.-F., Comparing the magnetic property of shell thickness controlled of Ag–Ni core-shell nanoparticles, J. Appl. Phys., 2014, vol. 115, p. 17B528.

Jing, J.J., Xie, J., Chen, G.Y., Li, W.H., and Hang, M.M., Preparation of nickel-silver core-shell nanoparticles by liquid-phase reduction for use in conductive paste, J. Exp. Nanosci., 2015, vol. 15, pp. 1347–1356.

He, J.H., Sheng, H.W., Schilling, P.J., Chien, C.-L., and Ma, E., Amorphous structures in the immiscible Ag–Ni system, Phys. Rev. Lett., 2001, vol. 86, pp. 2826–2829.

FUNDING

The synthesis and study of bimetallic 77 Ni–23 Ag particles and specimens made of them were carried out under the financial support of the Russian Science Foundation (project no. 17-19-01319). The synthesis and study of Ni nanoparticles and specimens made of them were carried out within the Program of Fundamental Scientific Research of the State Academies of Sciences for 2013–2020, direction III.23.

CONFLICT OF INTERESTS

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by E. Oborin

Rights and permissions

About this article

Cite this article

Sharipova, A.F., Bakina, O.V., Lozhkomoev, A.S. et al. Cold Sintering of Ni–Ag Nanocomposite Particles Produced by Electric Explosion of Wires. Inorg. Mater. Appl. Res. 10, 691–698 (2019). https://doi.org/10.1134/S2075113319030389

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113319030389