Abstract

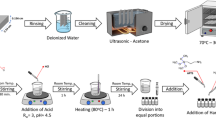

Epoxy-silica based hybrid nanocomposite coatings have been developed with different organicinorganic contents by sol–gel process. Various ratios of ceria and zirconia colloidal dispersions as inorganic nanoparticles are uniformly distributed in the hybrid sol. The hybrid sols are prepared by hydrolysis and condensation of 3-glycidoxypropyltrimethoxysilane (GPTMS) and tetraethylorthosilicate (TEOS) in acidic solution using bisphenol A (BPA) and 1-methyl-imidazol (MI). A thin layer of each sol is coated on a micro-glass slide and 1050 aluminum alloy as substrates. The effect of alkoxysilane precursors (i.e. TEOS and GPTMS) and inorganic to organic molar ratio are investigated. Nanoindentation and dynamic mechanical analysis (DMA) performed to characterize the mechanical properties of the coatings in nanorange scale. It is revealed that all hybrid nanocomposite coatings had appropriate flexibility and strong interfacial interaction with the aluminum alloy substrate. It is proposed that the ceria and zirconia nanoparticles can be bonded to the surrounding of siloxane ring which can be induced high restriction in polymeric chain mobility in dynamic mechanical analysis. Nanoindentation tests showed that by increasing the inorganic phase in the nanocomposite, both elastic modulus and hardness increase, especially they are very intense in the higher levels of inorganic content.

Similar content being viewed by others

References

A. Lutz, O. V. D. Berg, J. V. Damme, K. Verheyen, E. Bauters, I. D. Graeve, F. E. D. Prez, and H. Terryn, ACS Appl. Mater. Interfaces 7, 175 (2015).

U. Riaz, C. Nwaoha, and S. M. Ashraf, Prog. Org. Coat. 77, 743 (2014).

D. Landolt, Corrosion and Surface Chemistry of Metals (CRC Press, Boca Raton, FL, 2007), pp. 513–584.

H. J. Glasel, F. Bauer, H. Ernst, M. Findeisen, E. Hartmann, and H. Langguth, Macromol. Chem. Phys. 201, 2765 (2000).

S. Sepeur, N. Kunze, B. Werner, and H. Schmidt, Thin Solid Films 35, 216 (1999).

A. Ershad-Langroudi and A. Rahimi, Iran. Polym. J. 23, 267 (2014).

Y. Z. K. Lahijani, M. Mohseni, and S. Bastani, J. Coat. Technol. Res. 10, 537 (2013).

S. Sun, C. Li, L. Zhang, H. L. Du, and J. S. Burnell-Gray, Eur. Polym. J. 42, 1643 (2006).

M. Iijima, M. Tsukada, and H. Kamiya, J. Colloid Interface Sci. 307, 418 (2007).

M. Rostami, M. Mohseni, and Z. Ranjbar, Pigm. Resin Technol. 40, 363 (2011).

D. Işın, N. Kayaman-Apohan, and G. Güngör, Prog. Org. Coat. 65, 477 (2009).

J. C. Tan and A. K. Cheetham, Chem. Soc. Rev. 40, 1059 (2011).

D. Guo, G. Xie, and J. Luo, J. Phys. D: Appl. Phys. 47, 013001 (2014).

C. Sanchez, C. Boissière, D. Grosso, C. Laberty, and L. Nicole, Chem. Mater. 2, 682 (2008).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 19, 3 (2004).

J. L. Hay and G. M. Pharr, “Instrumented Indentation Testing,” in ASM Handbook, Vol. 8: Mechanical Testing and Evaluation, Ed. by H. Kuhn and D. Medlin, 10th ed. (ASM International, Materials Park, OH, 2000), pp. 232–243.

Q. Kan, W. Yan, G. Kang, and Q. Sun, J. Mech. Phys. Solids 61, 2015 (2013).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 7, 1564 (1992).

I. N. Sneddon, Int. J. Eng. Sci. 3, 47 (1965).

L. Cheng, X. Xia, W. Yu, L. E. Scriven, and W. W. Gerberich, J. Polym. Sci., Part B: Polym. Phys. 38, 10 (2000).

H. Lu, B. Wang, J. Ma, G. Huang, and H. Viswanathan, Mech. Time-Depend. Mater. 7, 189 (2003).

G. Huang, B. Wang, and H. Lu, Mech. Time-Depend. Mater. 8, 345 (2004).

X. Li and B. Bhushan, Mater. Charact. 48, 11 (2002).

J. Chen, J. Phys. D: Appl. Phys. 45, 203001 (2012).

C. McManamon, J. P. de Silva, J. Power, S. Ramirez-Garcia, M. A. Morris, and G. L. W. Cross, Langmuir 30, 11412 (2014).

G. Rivero, L. A. Fasce, S. M. Ceré, and L. B. Manfredi, Prog. Org. Coat. 77, 247 (2014).

X. Zhang, L. Hu, and D. Sun, Acta Mater. 54, 5469 (2006).

M. M. Shokrieh, M. R. Hosseinkhani, M. R. Naimi-Jamal, and H. Tourani, Polym. Test. 32, 45 (2013).

A. Tiwari and L. H. Hihara, Prog. Org. Coat. 77, 1200 (2014).

A. Allahverdi, M. Ehsani, H. Janpour, and S. Ahmadi, Prog. Org. Coat. 75, 543 (2012).

M. Zhai and G. B. McKenna, J. Polym. Sci., Part B: Polym. Phys. 52, 633 (2014).

R. Zandi-zand, A. Ershad-langroudi, and A. Rahimi, Prog. Org. Coat. 53, 286 (2005).

R. Zandi-zand, A. Ershad-langroudi, and A. Rahimi, J. Non-Cryst. Solids 351, 1307 (2005).

H. Abdollahi, A. Ershad-Langroudi, A. Salimi, and A. Rahimi, Ind. Eng. Chem. Res. 53, 10858 (2014).

ISO 14577: Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method, International Organization for Standardization, 2002.

A. Ershad Langroudi, Int. J. Bio-Inorg. Hybrid. Nanomater. 2, 337 (2013).

M. R. Naimi-Jamal and G. Kaupp, Z. Metallkd. 96, 1226 (2005).

H. Aguiar, J. Serra, P. Gonzalez, and B. León, J. Non-Cryst. Solids 355, 475 (2009).

C. Jäger, P. Hartmann, R. Witter, and M. Braun, J. Non-Cryst. Solids 263–264, 61 (2000).

M. Magi, E. Lippmaa, A. Samoson, G. Engelhardt, and A. R. Grimmer, J. Phys. Chem. 88, 1518 (1984).

J. Gonzalez-Hernández, J. F. Pérez-Robles, F. Ruiz, and J. R. Martínez, Superficies Vacio 11, 1 (2000).

H. Yahyaei and M. Mohseni, Tribol. Int. 57, 147 (2013).

H. Yahyaei, M. Mohseni, and S. Bastani, in Proceeding of Seventh Coating Science International Conference, Noordwijk, Netherlands, 2011 (Noordwijk, Netherlands, 2011).

R. Kasemann and H. Schmidt, in Proceeding of First European Workshop on Hybrid Organic–Inorganic Materials, Chateau de Bierville, France, 1993 (Chateau de Bierville, France, 1993), p. 171.

A. Allahverdi, M. Ehsani, H. Janpour, and S. Ahmadi, Prog. Org. Coat. 75, 543 (2012).

X. Li and G. B. McKenna, ACS Macro Lett. 1 (3), 388 (2012).

R. Y. Kannan, H. J. Salacinski, P. E. Butler, and A. M. Seifalian, Acc. Chem. Res. 38, 879 (2005).

L. Gan, J. Wang, and R. M. Pilliar, Biomaterials 26, 189 (2005).

H. Bei, Y. F. Gao, S. Shim, E. P. George, and G. M. Pharr, Phys. Rev. B 77, 060103 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Ershad-Langroudi, A., Zare, D. & Rahimi, A. Effect of ceria and zirconia nanoparticles on mechanical behavior of nanocomposite hybrid coatings. Polym. Sci. Ser. A 59, 425–436 (2017). https://doi.org/10.1134/S0965545X1703004X

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X1703004X