Abstract

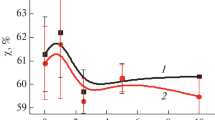

Bulk specimens of GUR 4150 ultra-high-molecular-weight polyethylene with a molar mass of 9.2 · 106 g/mol are obtained by cyclic impact compaction. During compaction, the material remains in the solid state, which ensures the preservation of the crystalline phase with a volume fraction of up to 66%. The strength properties of the specimens are not inferior to those of the products obtained using the industrial hot molding process. It is shown that the method described here is suitable for producing compacts with micro- and nanosized additives.

Similar content being viewed by others

References

G. E. Selyutin, Yu. Yu. Gavrilov, E. N. Voskresenskaya, et al., “Composite Materials Based on Ultra High Molecular Weight Polyethylene: Properties, Application Prospects,” Khimiya v Interesakh Ustoichovogo Razvitiya 18 (3), 375–388 (2010).

K. V. Shapkin, S. A. Ivanov, D. O. Zavrazhin, et al., “Solid-State Pressure Treatment of Polymer Composites Based on Ultra High Molecular Weight Polyethylene,” Perspekt. Mater., No. 11, 455–461 (2011).

Yu. A. Mikhailin, “Ultra High Molecular Weight Polyethylene,” Polymer. Mater., No. 3, 18–21 (2003).

Yu. A. Mikhailin, “Ultra High Molecular Weight Polyethylene,” Polymer. Mater., No. 4, 24–27 (2003).

Yu. A. Mikhailin, “Ultra High Molecular Weight Polyethylene,” Polymer. Mater., No. 6, 22–24 (2003).

Yu. A. Mikhailin, “Ultra High Molecular Weight Polyethylene,” Polymer. Mater., No. 7, 16–19 (2003).

N. A. Adamenko, Yu. P. Trykov, and A. V. Fetisov, “Polymer and Metal Polymer Materials Obtained by Explosive Processing,” Perspekt. Mater., No. 3, 63–68 (2004).

D. Jauffres, O. Lame, G. Vigier, F. Dore, “Microstructural Origin of Physical and Mechanical Properties of Ultra High Molecular Weight Polyethylene Processed by High Velocity Compaction,” Polymer 48 (21), 6374–6383 (2007).

O. V. Gogoleva, P. N. Petrova, S. N. Popov, and A. A. Okhlopkova, “Wear-Resistant Composite Materials Based on Ultra High Molecular Weight Polyethylene and Basalt Fibers,” Trenie i Iznos 36 (4), 394–399 (2015) [J. Friction Wear 36 (4), 301–305 (2015)].

V. A. Poluboyarov, Z. A. Korotaeva, I. A. Pauli, et al., “Modification of Polymers by Nanodispersed Ceramic Particles,” Khimiya v Interesakh Ustoichovogo Razvitiya 22 (4), 401–407 (2014).

V. A. Poluboyarov, O. V. Andryushkova, I. A. Pauli, and Z. A. Korotaeva, The Effect of Mechanical Loading on the Physicochemical Processes in Solids (Novosibirsk State Technical University, Novosibirsk, 2011) [in Russian].

V. F. Nesterenko, Impulse Loading of Heterogeneous Materials (Nauka, Novosibirsk, 1992) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © B.S. Zlobin, A.A. Shtertser, V.V. Kiselev, S.D. Shemelin, V.A. Poluboyarov, A.A. Zhdanok.

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 58, No. 3, pp. 68–76, May–June, 2017.

Rights and permissions

About this article

Cite this article

Zlobin, B.S., Shtertser, A.A., Kiselev, V.V. et al. Cyclic impact compaction of ultra high molecular weight polyethylene powder. J Appl Mech Tech Phy 58, 435–442 (2017). https://doi.org/10.1134/S0021894417030087

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894417030087