Abstract

Optogenetic probes can be powerful tools for dissecting complexity in cell biology, but there is a lack of instrumentation to exploit their potential for automated, high-information-content experiments. This protocol describes the construction and use of the optoPlate-96, a platform for high-throughput three-color optogenetics experiments that allows simultaneous manipulation of common red- and blue-light-sensitive optogenetic probes. The optoPlate-96 enables illumination of individual wells in 96-well microwell plates or in groups of wells in 384-well plates. Its design ensures that there will be no cross-illumination between microwells in 96-well plates, and an active cooling system minimizes sample heating during light-intensive experiments. This protocol details the steps to assemble, test, and use the optoPlate-96. The device can be fully assembled without specialized equipment beyond a 3D printer and a laser cutter, starting from open-source design files and commercially available components. We then describe how to perform a typical optogenetics experiment using the optoPlate-96 to stimulate adherent mammalian cells. Although optoPlate-96 experiments are compatible with any plate-based readout, we describe analysis using quantitative single-cell immunofluorescence. This workflow thus allows complex optogenetics experiments (independent control of stimulation colors, intensity, dynamics, and time points) with high-dimensional outputs at single-cell resolution. Starting from 3D-printed and laser-cut components, assembly and testing of the optoPlate-96 can be accomplished in 3–4 h, at a cost of ~$600. A full optoPlate-96 experiment with immunofluorescence analysis can be performed within ~24 h, but this estimate is variable depending on the cell type and experimental parameters.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data described in the article will be made available upon reasonable request to the corresponding author.

Code availability

All design files and code needed for optoPlate construction and operation are provided within the public GitHub repository at the following link: http://bit.ly/optoPlate96. Design files, code, and updates can also be accessed through a dedicated optoPlate-96 webpage found at http://www.bugajlab.com/optoplate-96.

References

Repina, N. A., Rosenbloom, A., Mukherjee, A., Schaffer, D. V. & Kane, R. S. At light speed: advances in optogenetic systems for regulating cell signaling and behavior. Ann. Rev. Chem. Biomol. Eng. 8, 13–39 (2017).

Salomon, M., Christie, J. M., Knieb, E., Lempert, U. & Briggs, W. R. Photochemical and mutational analysis of the FMN-binding domains of the plant blue light receptor, phototropin. Biochemistry 39, 9401–9410 (2000).

Fankhauser, C. The phytochromes, a family of red/far-red absorbing photoreceptors. J. Biol. Chem. 276, 11453–11456 (2001).

Adrian, M., Nijenhuis, W., Hoogstraaten, R. I., Willems, J. & Kapitein, L. C. A phytochrome-derived photoswitch for intracellular transport. ACS Synth. Biol. 6, 1248–1256 (2017).

Müller, K., Engesser, R., Timmer, J., Zurbriggen, M. D. & Weber, W. Orthogonal optogenetic triple-gene control in mammalian cells. ACS Synth. Biol. 3, 796–801 (2014).

Bugaj, L. J. et al. Cancer mutations and targeted drugs can disrupt dynamic signal encoding by the Ras–Erk pathway. Science 361, eaao3048 (2018).

Gerhardt, K. P. et al. An open-hardware platform for optogenetics and photobiology. Sci. Rep. 6, 35363 (2016).

Hannanta-anan, P. & Chow, B. Y. Optogenetic control of calcium oscillation waveform defines NFAT as an integrator of calcium load. Cell Syst. 2, 283–288 (2016).

Chen, M., Mertiri, T., Holland, T. & Basu, A. S. Optical microplates for high-throughput screening of photosynthesis in lipid-producing algae. Lab Chip 12, 3870–3874 (2012).

Davidson, E. A., Basu, A. S. & Bayer, T. S. Programming microbes using pulse width modulation of optical signals. J. Mol. Biol. 425, 4161–4166 (2013).

Hennemann, J. et al. Optogenetic control by pulsed illumination. ChemBioChem 19, 1296–1304 (2018).

Richter, F. et al. Upgrading a microplate reader for photobiology and all-optical experiments. Photochem. Photobiol. Sci. 14, 270–279 (2015).

Guntas, G. et al. Engineering an improved light-induced dimer (iLID) for controlling the localization and activity of signaling proteins. Proc. Natl. Acad. Sci. USA 112, 112 (2015).

Levskaya, A., Weiner, O. D., Lim, W. A. & Voigt, C. A. Spatiotemporal control of cell signalling using a light-switchable protein interaction. Nature 461, 997–1001 (2009).

Chen, S. Y. et al. Optogenetic control reveals differential promoter interpretation of transcription factor nuclear translocation dynamics. Preprint at https://www.biorxiv.org/content/10.1101/548255v2 (2019).

Lin, J.-R., Fallahi-Sichani, M. & Sorger, P. K. Highly multiplexed imaging of single cells using a high-throughput cyclic immunofluorescence method. Nat. Commun. 6, 8390 (2015).

Gut, G., Herrmann, M. D. & Pelkmans, L. Multiplexed protein maps link subcellular organization to cellular states. Science 361, eaar7042 (2018).

Carpenter, A. E. et al. CellProfiler: image analysis software for identifying and quantifying cell phenotypes. Genome Biol. 7, R100 (2006).

Goglia, A. G., Wilson, M. Z., DiGiorno, D. B. & Toettcher, J. E. in Kinase Signaling Networks (eds Tan, A.-C. & Huang, P. H.) 3–20 (Springer, New York, 2017).

Jones, T. R. et al. CellProfiler analyst: data exploration and analysis software for complex image-based screens. BMC Bioinformatics 9, 482 (2008).

Toettcher, J. E., Gong, D., Lim, W. A. & Weiner, O. D. Light-based feedback for controlling intracellular signaling dynamics. Nat. Meth. 8, 837–839 (2011).

Suh, B.-C., Inoue, T., Meyer, T. & Hille, B. Rapid chemically induced changes of PtdIns(4,5)P2 gate KCNQ ion channels. Science 314, 1454–1457 (2006).

Acknowledgements

We thank N. Repina (UC Berkeley), R. Almeida, and A. Mitchell for helpful discussions on optoPlate and software design. We thank A. Mitchell, G. O’Donoghue, and X. Xiong for testing and troubleshooting the optoPlate and operational protocols. We thank S. Laub and D. Gonzalez-Martinez for critical editing of the protocol. This work was funded by an Arnold O. Beckman Postdoctoral Fellowship (L.J.B.), the Howard Hughes Medical Institute (W.A.L), and NIH grants P50GM081879 and R01GM55040 (W.A.L).

Author information

Authors and Affiliations

Contributions

L.J.B. designed, built, tested, and characterized the optoPlate-96. L.J.B. wrote the code to run and analyze optoPlate-96 experiments. L.J.B. performed and analyzed all optoPlate-96 experiments. L.J.B. wrote the manuscript, with editing from W.A.L. L.J.B and W.A.L made figures. W.A.L. oversaw the development of the optoPlate-96.

Corresponding author

Ethics declarations

Competing interests

L.J.B. and W.A.L. have submitted a patent application describing the optoPlate-96 (no. 15/651628).

Additional information

Peer review information: Nature Protocols thanks Amar Basu and other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Key reference using this protocol

Bugaj, L. J. et al. Science 361, eaao3048 (2018): https://science.sciencemag.org/content/361/6405/eaao3048

Integrated supplementary information

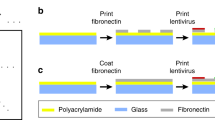

Supplementary Fig. 1 Orthogonal stimulation of red- and blue-sensitive optogenetic probes requires simultaneous control over three wavelengths of light.

a) PhyB/PIF and iLid/sspB are red- and blue-light responsive heterodimers, respectively. b) While iLid does not absorb light beyond 500 nm, PhyB absorbs light across the visible spectrum, challenging orthogonal multiplexing. Lines above absorption spectra indicate the wavelengths used for activation. Spectra are adapted from prior literature2,3. c) Far-red light can be applied concurrently with blue light to avoid PhyB cross-activation.

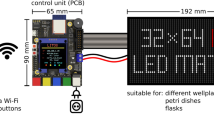

Supplementary Fig. 2 The optoPlate-96 illuminator.

The assembled optoPlate-96 illuminator is depicted and important features are highlighted. An Arduino Micro microcontroller plugs into the illuminator. The Arduino stores and executes the illumination program, eliminating the need for external data cables. Only power cables must be connected to the illuminator during an experiment. The illuminator was designed with four barrel-jack connectors to accommodate different voltage requirements for different components. While the fan must be supplied with 12V and the Arduino with >7V, the LEDs should be supplied with the minimum voltage that maximizes brightness. This will vary for individual LEDs, but we find that ~4V for red and far-red LEDs and ~5V for blue LEDs is suitable. LED voltage above this minimum will generate heat in the LED driver chips, and thus should be avoided. The optoPlate-96 illuminator depicted will illuminate three colors -- blue, red, and far-red. In principle, the illuminator can be used with LEDs of any color, provided that the LEDs are in a PLCC2 or PLCC4 package and the polarity of the LED terminals is compatible with the PCB design.

Supplementary Fig. 3 Linear control of illumination intensity.

Programmed light intensity settings are linearly correlated to measured light output. Blue light power density from a 1-color (blue) optoPlate-96 was measured. Data represent means of three readings from 2 independent wells per condition. Error bars indicate range. Power was measured using a Thorlabs PM20A power meter coupled to a multimode optical fiber (Thorlabs M71L01). Light was collected by placing the fiber at the bottom of a 96-wellplate well that was sitting atop the optoPlate adaptor. Due to inefficiencies in light capture and losses in light transmission to the power meter, the power densities presented here underestimate the blue light power density at the sample.

Supplementary Fig. 4 The optoPlate-96 adapter and lid.

a,b) The optoPlate-96 adapter couples the optoPlate illuminator to microwell plates. c,d) The adapter features 96 openings that accommodate either 96-well or 384-well plates. For 384-well plates, 4 wells are illuminated through each opening. To ensure even illumination across the microwell, diffuser paper squares can be inserted into each opening to rest on the 4 radially-positioned nubbins within each adapter opening. It is important to note that diffuser squares reduce the amount of light that illuminates the sample, which can be an important tradeoff depending on the particular optogenetic system. In the event that LED intensity is limiting, diffuser paper may be removed to maximize photon flux. However, this is not recommended for 384 well experiments, since each of the 4 wells per channel may experience different intensities of optical stimulation. Lids for 96-well (e) and 384-well (f) optoPlate experiments are depicted. Lids feature protrusions that fit into each individual well in order to ensure optical insulation between wells. Both adapter and lid can be 3D printed using the design files provided.

Supplementary Fig. 5 LED polarity and orientation on the optoPlate illuminator.

a) The polarity of the LED pads is indicated. b,c,d) LED polarity is typically indicated on the LED case with a clipped corner. The pole indicated by the clipped corner varies by LED part number, so always double check the LED product sheet before assembly. Proper orientation for LEDs in the 1-color (b), 2-color (c), and 3-color (d) configurations is depicted. Clipped corners are represented by red triangles.

Supplementary Fig. 6 OptoPlate-96 thermal management.

a) The optoPlate-96 includes an active heatsink to homogenize and minimize heat transfer to the samples. An aluminum plate is positioned under the illuminator, and a thermal pad between the plate and illuminator enhances heat transfer between two. An active heatsink is then positioned under the aluminum plate, and the entire assembly is fixed to the illuminator using the heatsink bolts and hex nuts. OptoPlate heating can arise from many factors, including large current draws, low fan speed, and oversupply of LED voltage. Thus, each individual protocol will have unique heating profiles and should ideally be measured empirically before each experiment (most easily by measuring PBS temperature in a 96-well plate during an optoPlate run at the bench). To measure heating systematically, we built a 12-channel temperature sensor (b) using the 10K Precision Epoxy Thermistor from Adafruit. With this device, we could simultaneously measure temperature changes in different locations during an optoPlate run (c). d) Different illumination profiles lead to different sample heating profiles. As the total current/light-flux decreases, heating above baseline decreases. Notably, heating between different plate locations is uniform (within 0.5–1°C). Certain illumination profiles (500 ms ON, 4500 ms OFF) generate no sample heating over long periods (10h shown). Heating traces are organized by variation along columns (top) or rows (bottom). Colors of traces correspond to well locations in (c). Difference in temperature baselines reflects differences in ambient temperature between experiments.

Supplementary Fig. 7 LED driver map.

a) Locations are indicated for the drivers and pins that control individual LED channels for the 3-color configuration. Each driver controls 24 channels. The drivers for red and blue LEDs drive 3 columns of LEDs each. The drivers for far-red LEDs drive 2 rows each. b) Each of the 96 well positions is controlled by three separate driver chips corresponding to the three different color labels. The correspondence between driver color label and LED pads is depicted.

Supplementary Fig. 8 L-brackets hold the PCB in place while solder paste is applied.

Left: L-brackets are used to hold the PCB in place while solder paste is applied. Right: An example of a PCB being held in place by L-brackets.

Supplementary Fig. 9 LED driver orientation and voltage regulator layout.

LED drivers are oriented as indicated. Red dots represent the location of Pin 1. Voltage regulators are circled in red.

Supplementary Fig. 10 Capacitor layout.

Capacitors are positioned on the optoPlate-96 as indicated. The capacitors smooth out power supply fluctuations for integrated circuits. Capacitor values were chosen according to manufacturer specifications. Capacitor placement is the same for all optoPlate configurations.

Supplementary Fig. 11 Resistor and transistor layout.

Resistor placement is indicated for each of the three optoPlate illuminator conditions. Only one resistor per LED driver chip varies between configurations. This resistor (1.65 or 9.76 kOhm) specifies the current that is drawn through each LED control pin on the driver chip. Because current level defines LED intensity, this resistor defines the dynamic range of the LEDs controlled by the associated driver. The relationship between resistor value and current level can be found on the product sheet for the TLC5947 driver chips (http://bit.ly/tlc5947). The PNP transistor placement (green) is the same for each configuration. This transistor maintains all LEDs in the OFF state unless the Arduino program is running. This prevents transient illumination of LEDs when the LED power supply is attached.

Supplementary Fig. 12 optoSOS component levels affect dynamic range but not activation kinetics of Erk signaling.

Extended analysis of optoSOS optimization in HEK 293T cells, from Fig. 4. a) Comparison of stimulated and unstimulated samples shows that high phycocyanobilin (PCB) and high PhyB levels are critical for a large dynamic range of Erk signaling. Large dynamic range can be achieved even at low PIF-sos2cat expression levels. b) Median ppErk levels were extracted for each expression condition within each timepoint. ppErk levels were normalized, and ppErk decay after optoSOS shut-off was fit to a single exponential. We found that, despite differences in dynamic range (a), pathway decay kinetics were independent of optoSOS component concentration. c) All conditions exhibit a ~2 min half-life of pathway decay, with noisy measurements under low phycocyanobilin concentration likely due to the small dynamic range of stimulation.

Supplementary information

Supplementary Figures 1–12

Supplementary Figures 1–12

Rights and permissions

About this article

Cite this article

Bugaj, L.J., Lim, W.A. High-throughput multicolor optogenetics in microwell plates. Nat Protoc 14, 2205–2228 (2019). https://doi.org/10.1038/s41596-019-0178-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41596-019-0178-y

This article is cited by

-

High-throughput feedback-enabled optogenetic stimulation and spectroscopy in microwell plates

Communications Biology (2023)

-

Optogenetic control of YAP reveals a dynamic communication code for stem cell fate and proliferation

Nature Communications (2023)

-

Neural engineering with photons as synaptic transmitters

Nature Methods (2023)

-

Temperature-responsive optogenetic probes of cell signaling

Nature Chemical Biology (2022)

-

LITOS: a versatile LED illumination tool for optogenetic stimulation

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.