Abstract

Despite the intense interest in metallic glasses for a variety of engineering applications, many details of their structure remain a mystery. Here, we present the first compelling atomic structural model for metallic glasses. This structural model is based on a new sphere-packing scheme—the dense packing of atomic clusters. Random positioning of solvent atoms and medium-range atomic order of solute atoms are combined to reproduce diffraction data successfully over radial distances up to ∼1 nm. Although metallic glasses can have any number of chemically distinct solute species, this model shows that they contain no more than three topologically distinct solutes and that these solutes have specific and predictable sizes relative to the solvent atoms. Finally, this model includes defects that provide richness to the structural description of metallic glasses. The model accurately predicts the number of solute atoms in the first coordination shell of a typical solvent atom, and provides a remarkable ability to predict metallic-glass compositions accurately for a wide range of simple and complex alloys.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Klement, W., Willens, R.H. & Duwez, P. Non-crystalline structure in solidified gold-silicon alloys. Nature 187, 869–870 (1960).

Bernal, J.D. & Mason, J. Co-ordination of randomly packed spheres. Nature 188, 910–911 (1960).

Scott, G.D. Packing of spheres. Nature 188, 908–909 (1960).

Finney, J.L. Random packings and the structure of simple liquids I. The geometry of random close packing. Proc. Roy. Soc. Lond. A 319, 479–493 (1970).

Gaskell, P.H. A new structural model for transition metal-metalloid glasses. Nature 276, 484–485 (1978).

Gaskell, P.H. A new structural model for amorphous transition metal silicides, borides, phosphides and carbides. J. Non-Cryst. Solids 32, 207 (1979).

Dubois, J.M., Gaskell, P.H. & Le Caer, G. A model for the structure of metallic glasses based on chemical twinning. Proc. Roy. Soc. A 402, 323–357 (1985).

Gaskell, P.H. in Materials Science and Technology (ed. Zarzycki, J.) 175–278 (VCH, Cambridge, UK, 1991).

Miracle, D.B., Sanders, W.S. & Senkov, O.N. The influence of efficient atomic packing on the constitution of metallic glasses. Phil. Mag. A 83, 2409–2428 (2003).

Miracle, D.B. & Senkov, O.N. A geometric model for atomic configurations in amorphous Al alloys. J. Non-Cryst. Solids 319, 174–191 (2003).

Miracle, D.B. Efficient local packing in metallic glasses. J. Non-Cryst. Solids (in the press).

Mackay, A.L., Finney, J.L. & Gotoh, K. The closest packing of equal spheres on a spherical surface. Acta Crystallogr. A33, 98–100 (1977).

Clare, B.W. & Kepert, D.L. The optimal packing of circles on a sphere. J. Math. Chem. 6, 325–349 (1991).

Sloane, N.J.A. Kepler's conjecture confirmed. Nature 395, 435–436 (1998).

Gaskell, P.H. in Glassy Metals II (eds Beck, H. & Guntherodt, H.-J.) 5–49 (Springer, Berlin, Germany, 1983).

Sietsma, J. & Thijsse, B.J. An investigation of universal medium range order in metallic glasses. J. Non-Cryst. Solids 135, 146–154 (1991).

Lamparter, P. & Steeb, S. in Structure of Solids (ed. Gerold, V.) 217–288 (VCH, Weinheim, Germany, 1993).

Hufnagel, T.C. & Brennan, S. Short- and medium-range order in (Zr70Cu20Ni10)90-xTaxAl10 bulk amorphous alloys. Phys. Rev. B 67, 014203 (2003).

Gaskell, P.H. On the structure of simple inorganic amorphous solids. J. Phys. C Phys. 12, 4337–4368 (1979).

Stephens, P.W. in Extended Icosahedral Structures (eds Jaric, M.V. & Gratias, D.) 37–104 (Academic, Boston, Massachusetts, USA, 1989).

Aste, T. & Weaire, D. The Pursuit of Perfect Packing (Institute of Physics, Bristol, UK, 2000).

Ponnambalam, V. et al. Synthesis of iron-based bulk metallic glasses as nonferromagnetic amorphou steel alloys. Appl. Phys. Lett. 83, 1131–1133 (2003).

Ponnambalam, V., Poon, S.J. & Shiflet, G.J. Fe-based bulk metallic glasses with diameter thickness larger than one centimeter. J. Mat. Res. 19, 1320–1323 (2004).

Inoue, A., Kato, A., Zhang, T., Kim, S.G. & Masumoto, T. Mg-Cu-Y amorphous alloys with high mechanical strengths produced by a metallic mold casting method. Mater. Trans. JIM 32, 609–616 (1991).

Cahn, J.W. & Bendersky, L.A. in Amorphous and Nanocrystalline Metals (eds Busch, R. et al.) 139–143 (Materials Research Society, Warrendale, Pennsylvania, 2004).

Nold, E., Lamparter, P., Olbrich, H., Rainer-Harbach, G. & Steeb, S. Determination of the Partial Structure Factors on the Metallic Glass Fe80B20 . Z. Naturforsch. 36a, 1032–1044 (1981).

Lamparter, P., Sperl, W., Steeb, S. & Bletry, J. Atomic structure of amorphous metallic Ni81B19 . Z. Naturforsch. 37a, 1223–1234 (1982).

Sadoc, J.F. & Dixmier, J. Structural investigation of amorphous CoP and NiP Alloys by combined X-ray and neutron scattering. Mater. Sci. Eng. 23, 187–192 (1976).

Matsubara, E., Waseda, Y., Inoue, A., Ohtera, H. & Masumoto, T. Anomalous X-ray scattering on amorphous Al87Y8Ni5 and Al90Y10 alloys. Z. Naturforsch. 44a, 814–820 (1989).

Matsubara, E. & Waseda, Y. Structural studies of new metallic amorphous alloys with wide supercooled liquid region (Overview). Mater. Trans. JIM 36, 883–889 (1995).

Cowlam, N., Guoan, W., Gargner, P.P. & Davies, H.A. Ni64B36 - A transition metal-metalloid glass with first neighbor metalloid atoms. J. Non-Cryst. Solids 61-62, 337–342 (1984).

Steeb, S. & Lamparter, P. Structure of binary metallic glasses. J. Non-Cryst. Solids 156–158, 24–33 (1993).

Pauling, L. The Nature of the Chemical Bond (Cornell Univ. Press, Ithaca, NewYork, 1960).

Slater, J.C. Atomic radii in crystals. J. Chem. Phys. 41, 3199–3204 (1964).

Egami, T. & Waseda, Y. Atomic size effect on the formability of metallic glasses. J. Non-Cryst. Solids 64, 113–134 (1984).

Daams, J.L.C., Villars, P. & van Vucht, J.H.N. Atlas of Crystal Structure Types for Intermetallic Phases (ASM, International, Metals Park, Ohio, 1991).

Poon, S.J., Shiflet, G.J., Guo, F.Q. & Ponnambalam, V. Glass formability of ferrous- and aluminum-based structural metallic alloys. J. Non-Cryst. Solids 317, 1–9 (2003).

Kasper, J.S. & Lonsdale, K. (eds) International Tables for X-Ray Crystallography (Kluwer Academic, Dordrecht, Holland, 1989).

Senkov, O.N. & Miracle, D.B. Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater. Res. Bull. 36, 2183–2198 (2001).

Lee, A., Etherington, G. & Wagner, C.N.J. Partial structure functions of amorphous Ni35Zr65 . J. Non-Cryst. Solids 61-62, 349–354 (1984).

Acknowledgements

I thank A. L. Greer and K.F. Kelton for critical comments on this manuscript. This research was supported under the Defense Advanced Research Projects Agency Structural Amorphous Metals Initiative (L. Christodoulou, Program Manager) and Air Force Office of Scientific Research Task 01ML05–COR (C. Hartley, Program Manager).

Author information

Authors and Affiliations

Ethics declarations

Competing interests

The author declares no competing financial interests.

Supplementary information

Rights and permissions

About this article

Cite this article

Miracle, D. A structural model for metallic glasses. Nature Mater 3, 697–702 (2004). https://doi.org/10.1038/nmat1219

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1219

This article is cited by

-

Unveiling the local structure of the amorphous metal \(\text {Fe}_{(1-x)}\text {Zr}_x\) combining first-principles-based simulations and modelling of EXAFS spectra

Scientific Reports (2023)

-

Size-dependent deformation behavior in nanosized amorphous metals suggesting transition from collective to individual atomic transport

Nature Communications (2023)

-

Non-affine atomic rearrangement of glasses through stress-induced structural anisotropy

Nature Physics (2023)

-

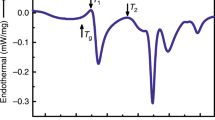

Local atomic structure studies of Zr55Cu35Al10 alloy around Tg

Scientific Reports (2023)

-

A Molecular Dynamics Study on the Local Structure of Al90Sm10 Marginal Metallic Glass and Liquid

Metallurgical and Materials Transactions A (2023)