Abstract

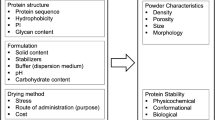

Purpose. To understand the effect of spray drying and powder processing environments on the residual moisture content and aerosol performance of inhalation protein powders. Also, the long-term effect of storage conditions on the powder's physical and biochemical stability was presented.

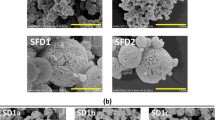

Methods. Excipient-free as well as mannitol-formulated powders of a humanized monoclonal antibody (anti-IgE) and recombinant human deoxyribonuclease (rhDNase) were prepared using a Buchi 190 model spray dryer. Residual moisture content and moisture uptake behavior of the powder were measured using thermal gravimetric analysis and gravimetric moisture sorption isotherm, respectively. Protein aggregation, the primary degradation product observed upon storage, was determined by size-exclusion HPLC. Aerosol performance of the dry powders was evaluated after blending with lactose carriers using a multi-stage liquid impinger (MSLI).

Results. Spray-dried powders with a moisture level (~ 3%) equivalent to the freeze-dried materials could only be achieved using high-temperature spray-drying conditions, which were not favorable to large-male manufacturing, or subsequent vacuum drying. These dry powders would equilibrate with the subsequent processing and storage environments regardless of the manufacturing condition. As long as the relative humidity of air during processing and storage was lower than 50%, powders maintained their aerosol performance (fine particle fraction). However, powders stored under drier conditions exhibited better long-term protein biochemical stability.

Conclusions. Manufacturing, powder processing, and storage environments affected powder's residual moisture level in a reversible fashion. Therefore, the storage condition determined powder's overall stability, but residual moisture had a greater impact on protein chemical stability than on powder physical stability.

Similar content being viewed by others

REFERENCES

L. N. Bell, M. J. Hageman, and J. M. Bauer. Impact of moisture on thermally induced denaturation and decomposition of lyophilized bovine somatotropin. Biopolym. 35:201–209 (1995).

L. N. Bell, M. J. Hageman, and L. M. Muraoka. Thermally induced denaturation of lyophilized bovine somatotropin and lysozyme as impacted by moisture and excipients. J. Pharm. Sci. 84:707–712 (1995).

M. J. Hageman. The role of moisture in protein stability. Drug Dev. Ind. Pharm. 14:2047–2070 (1988).

A. R. Clark, N. Dasovich, I. Gonda, and H.-K. Chan. The balance between biochemical and physical stability for inhalation protein powders: rhDNase as an example. In: R.N. Dalby, P.R. Byron, and S.J. Farr (eds.), Respiratory drug delivery V, Interpharm Press, Buffalo Grove, IL. pp. 167–174 (1996).

J. Broadhead, S. K. Edmont Rouan, and C. T. Rhodes. The deposition of spray-dried β-galactosidase from dry powder inhaler devices. Drug Dev. Ind. Pharm. 22:813–822 (1996).

R. N. Jashnani, P. R. Byron, and R. N. Dalby. Testing of dry powder aerosol formulation in different environmental conditions. Int. J. Pharm. 113:123–130 (1995).

M. J. Hageman, In T. J. Ahern and M. C. Manning (eds.), Stability of Protein Pharmaceuticals. Part A. Chemical and Physical Pathways of Protein Degradation, Plenum Press, New York, pp. 273–309 (1994).

H.-K, Chan, A. Clark, I. Gonda, M., Mumenthaler, and C. Hsu. Spray-dried powders of recombinant human deoxyribonuclease (rhDNase) for aerosol delivery. Pharm. Res. 14:431–437 (1997).

J. F. Young. Humidity control in the laboratory using salt solutions-A review. J. Appl. Chem. 17:241–245 (1967).

L, Greenspan, J. Research of the National Bureau of StandardsA. Physics and Chemistry. 81A:89–96 (1977).

Y. F. Maa, H. R. Costantino, P. A. Nguyen, and C. C. Hsu, C. C. The effect of operating and formulation variables on the morphology of spray-dried protein powders. Phar. Dev. Tech. 2:213–223 (1997).

P. Labrude, M. Rasolomanana, C. Vigneron, C. Thirion, B. Challot. Protective effect of sucrose on spray drying of oxyhemoglobin, J. Pharm. Sci. 78:223–229 (1989).

J. Broadhead, S. K. Edmon Rouan, I. Hau, C. T. Rhodes. The effect of process and formulation variables on the properties of spray-dried β-galactosidase. J. Pharm. Pharmacol. 64:458–467 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Maa, YF., Nguyen, PA., Andya, J.D. et al. Effect of Spray Drying and Subsequent Processing Conditions on Residual Moisture Content and Physical/Biochemical Stability of Protein Inhalation Powders. Pharm Res 15, 768–775 (1998). https://doi.org/10.1023/A:1011983322594

Issue Date:

DOI: https://doi.org/10.1023/A:1011983322594