Abstract

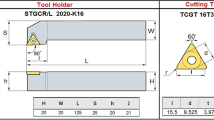

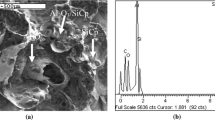

The present work investigates the influence of cutting parameters on the output responses such as temperature rise, chip formation, delamination, tool wear, and surface roughness during end milling of stir cast AA6351-B4C composite. The titanium nitride (TiN)-coated solid carbide tool with four flute end mill is used for the experiments. The thermography and scanning electron microscopy (SEM) images are used to analyze the effect of temperature rise on the chip formation and chip behavior. The increase in feed considerably increased the chip thickness from 0.7 to 1.2 mm at 2000 rpm. In addition to that, the formation of abrasive tool wear at minimum cutting speed has resulted with an increase in surface roughness. Further, the delamination of the slot entry surface is also assessed and achieved a lower delamination factor (<1.10) at 0.5 mm depth of cut condition. Finally, the desirability analysis is performed and found that the cutting speed at 2030 rpm, feed at 0.05 mm/tooth, and depth of cut at 0.5 mm are the suitable conditions to produce minimum temperature rise, lower delamination, and surface roughness simultaneously. The microscopic images revealed smooth surface with improved finish while machining at the optimum condition. The confirmation test results are also verified and found to be within 95% confidence and prediction intervals.

Similar content being viewed by others

References

Thirumalai Kumaran, S., Uthayakumar, M., Slota, A., Zajac, J.: Application of Grey relational analysis in high speed machining of AA (6351)-SiC-B4C hybrid composite. Int. J. Mater. Prod. Technol. 15(1), 17–31 (2015)

Kalaiselvan, K., Murugan, N., Parameswaran, S.: Production and characterization of AA6061–B4C stir cast composite. Mater. Des. 32(7), 4004–4009 (2011)

Varol, T., Canakci, A.: The effect of type and ratio of reinforcement on the synthesis and characterization cu-based nanocomposites by flake powder metallurgy. J. Alloys Compd. 649, 1066–1074 (2015)

Riaz Ahamed, A., Asokan, P., Aravindan, S.: EDM of hybrid al–SiCp–B4Cp and al–SiCp–Glassp MMCs. Int. J. Adv. Manuf. Technol. 44(5), 520–528 (2009)

Varol, T., Canakci, A.: Synthesis and characterization of nanocrystalline Al2024-B4C composite powders by mechanical alloying. Philos. Mag. Lett. 93(6), 339–345 (2013)

Varol, T., Canakci, A., Ozsahin, S.: Modeling of the prediction of densification behavior of powder metallurgy al-cu-mg/B4C composites using artificial neural networks. Acta Metall. Sin. Engl. Lett. 28(2), 182–195 (2015)

Varol, T., Canakci, A.: Microstructure, electrical conductivity and hardness of multilayer graphene/copper nanocomposites synthesized by flake powder metallurgy. Met. Mater. Int. 21(4), 704–712 (2015)

Canakci, A., Ozsahin, S., Varol, T.: Prediction of effect of reinforcement size and volume fraction on the abrasive wear behavior of AA2014/B4Cp MMCs using artificial neural network. Arab. J. Sci. Eng. 39(8), 6351–6361 (2014)

Canakci, A., Arslan, F., Varol, T.: Effect of volume fraction and size of B4C particles on production and microstructure properties of B4C reinforced aluminum alloy composites. Mater. Sci. Technol. 29(8), 954–960 (2013)

Sharma, V.S., Singh, G.R., Sørby, K.: A review on minimum quantity lubrication for machining processes. Mater. Manuf. Process. 30(8), 935–953 (2015)

Kundrák, J., Mamalis, A.G., Gyáni, K., Markopoulos, A.: Environmentally friendly precision machining. Mater. Manuf. Process. 21(1), 29–37 (2006)

Le Coz, G., Marinescu, M., Devillez, A., Dudzinski, D., Velnom, L.: Measuring temperature of rotating cutting tools: application to MQL drilling and dry milling of aerospace alloys. Appl. Therm. Eng. 36, 434–441 (2012)

Yashiro, T., Ogawa, T., Sasahara, H.: Temperature measurement of cutting tool and machined surface layer in milling of CFRP. Int. J. Mach. Tools Manuf. 70, 63–69 (2013)

Kim, S.W., Lee, C.M., Lee, D.W., Kim, J.S., Jung, Y.H.: Evaluation of the thermal characteristics in high-speed ball-end milling. J. Mater. Process. Technol. 113(1–3), 406–409 (2001)

Dewes, R.C., Ng, E., Chua, K.S., Newton, P.G., Aspinwall, D.K.: Temperature measurement when high speed machining hardened mould/die steel. J. Mater. Process. Technol. 92-93, 293–301 (1999)

Wissmiller, D.L., Pfefferkorn, F.E.: Micro end mill tool temperature measurement and prediction. J. Manuf. Process. 11(1), 45–53 (2009)

Pittalà, G.M., Monno, M.: A new approach to the prediction of temperature of the workpiece of face milling operations of Ti-6Al-4V. Appl. Therm. Eng. 31(2–3), 173–180 (2011)

Paulo Davim, J., Reis, P.: Damage and dimensional precision on milling carbon fiber-reinforced plastics using design experiments. J. Mater. Process. Technol. 160(2), 160–167 (2005)

Swain, N., Venkatesh, V., Kumar, P., Srinivas, G., Ravishankar, S., Barshilia, H.C.: An experimental investigation on the machining characteristics of Nimonic 75 using uncoated and TiAlN coated tungsten carbide micro-end mills. CIRP J. Manuf. Sci. Technol. 16, 34–42 (2017)

Hou, J., Zhou, W., Duan, H., Yang, G., Xu, H., Zhao, N.: Influence of cutting speed on cutting force, flank temperature, and tool wear in end milling of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 70(9), 1835–1845 (2014)

Pan, W., Kamaruddin, A., Ding, S., Mo, J.: Experimental investigation of end milling of titanium alloys with polycrystalline diamond tools. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 228(8), 832–844 (2014)

Kıvak, T.: Optimization of surface roughness and flank wear using the Taguchi method in milling of Hadfield steel with PVD and CVD coated inserts. Measurement. 50, 19–28 (2014)

Arun Premnath, A., Alwarsamy, T., Rajmohan, T.: Experimental investigation and optimization of process parameters in milling of hybrid metal matrix composites. Mater. Manuf. Process. 27(10), 1035–1044 (2012)

Mehfuz, R., Ali, M.Y.: Investigation of machining parameters for the multiple-response optimization of micro electrodischarge milling. Int. J. Adv. Manuf. Technol. 43(3), 264–275 (2009)

Praveen Raj, P., Elaya Perumal, A.: Taguchi analysis of surface roughness and delamination associated with various cemented carbide K10 end mills in milling of GFRP. J. Eng. Sci. Technol. Rev. 3(1), 58–64 (2010)

Thirumalai Kumaran, S., Uthayakumar, M., Aravindan, S., Rajesh, S.: Dry sliding wear behavior of SiC and B4C-reinforced AA6351 metal matrix composite produced by stir casting process. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 230(2), 484–491 (2016)

Samy, G.S., Thirumalai Kumaran, S.: Measurement and analysis of temperature, thrust force and surface roughness in drilling of AA (6351)-B4C composite. Measurement. 103, 1–9 (2017)

Ueda, T., Hosokawa, A., Oda, K., Yamada, K.: Temperature on flank face of cutting tool in high speed milling. Ann. CIRP. 50, 5–8 (2001)

Zhou, L., Wang, C.Y., Qin, Z.: Tool wear characteristics in high-speed milling of graphite using a coated carbide micro endmill. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 223(3), 267–277 (2008)

Jawaid, A., Koksal, S., Sharif, S.: Cutting performance and wear characteristics of PVD coated and uncoated carbide tools in face milling Inconel 718 aerospace alloy. J. Mater. Process. Technol. 116, 2–9 (2001)

Jenarthanan, M.P., Lakshman, P.A., Jeyapaul, R.: Mathematical modeling of delamination factor on end milling of hybrid GFRP composites through RSM. Pigm. Resin Technol. 45(5), 371–379 (2016)

Thirumalai Kumaran, S., Ko, T.J., Li, C., Yu, Z., Uthayakumar, M.: Rotary ultrasonic machining of woven CFRP composite in a cryogenic environment. J. Alloys Compd. 698, 984–993 (2017)

Acknowledgment

The authors thank the Centre for Advanced Machining (DST–FIST sponsored), Kalasalingam University, India, for the support to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samy, G.S., Thirumalai Kumaran, S. & Uthayakumar, M. An analysis of end milling performance on B4C particle reinforced aluminum composite. J Aust Ceram Soc 53, 373–383 (2017). https://doi.org/10.1007/s41779-017-0046-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-017-0046-6