Abstract

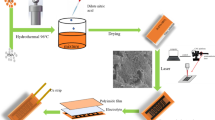

Aiming to produce electrically conductive polylactic acid (PLA), a reduced graphene oxide (rGO) with low oxygen content was prepared to produce PLA/rGO nanocomposites by melt compounding. The electrical conductivity of PLA/rGO composites improved significantly with the incorporation of rGO at a moderate filler loading, thanks to the large lateral size, low thickness, and low oxygen content of the rGO prepared. Filament for fused-deposition modeling has been produced based on the composite produced at 2% in weight with the purpose of producing devices for electronic applications. An all-polymer humidity sensor device has been prepared using the PLA/rGO filament produced demonstrating the ability to produce all-polymer devices.

Similar content being viewed by others

References

Murariu M, Dubois P (2016) PLA composites: from production to properties. Adv Drug Deliv Rev 107:17–46

Elsawy MA, Kim KH, Park JW, Deep A (2017) Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sustain Energy Rev 79:1346–1352

Sadasivuni KK, Ponnamma D, Thomas S, Grohens Y (2014) Evolution from graphite to graphene elastomer composites. Prog Polym Sci 39(4):749–780

Ho PKH, Thomas DS, Friend RH, Tessler N (1999) All-polymer optoelectronic devices. Science 285:233–236

Argun AA, Cirpan A, Reynolds JR (2003) The first truly all-polymer electrochromic devices. Adv Mater 15:1338–1341

Garnier F, Hajlaoui R, Yassar A, Srivastava P (1994) All-polymer field-effect transistor realized by printing techniques. Science 265(5179):1684–1686

Gofer Y, Sarker H, Killian JG, Poehler TO, Searson PC (1997) An all-polymer charge storage device. Appl. Phys. Lett. 71(11):1582–1584

Kim H, Miura Y, Macosko CW (2010) Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem Mater 22(11):3441–3450

Verma M, Chauhan SS, Dhawan SK, Choudhary V (2017) Graphene nanoplatelets/carbon nanotubes/polyurethane composites as efficient shield against electromagnetic polluting radiations. Compos B Eng 120:118–127

Norazlina H, Kamal Y (2015) Graphene modifications in polylactic acid nanocomposites: a review. Polym. Bull. 72(4):931–961

Shen Y et al (2012) Chemical and thermal reduction of graphene oxide and its electrically conductive polylactic acid nanocomposites. Compos Sci Technol 72(12):1430–1435

Gao Y, Picot OT, Bilotti E, Peijs T (2017) Influence of filler size on the properties of poly(lactic acid) (PLA)/graphene nanoplatelet (GNP) nanocomposites. Eur Polym J 86:117–131

Lei L, Qiu J, Sakai E (2012) Preparing conductive poly(lactic acid) (PLA) with poly(methyl methacrylate) (PMMA) functionalized graphene (PFG) by admicellar polymerization. Chem Eng J 209:20–27

Cai C, Liu L, Fu Y (2019) Processable conductive and mechanically reinforced polylactide/graphene bionanocomposites through interfacial compatibilizer. Polym Compos 40(1):389–400

Singh S, Ramakrishna S, Berto F (2019) 3D printing of polymer composites: a short review. Mater Des Process Commun. https://doi.org/10.1002/mdp2.97

Ivanova O, Williams C, Campbell T (2013) Additive manufacturing (AM) and nanotechnology: promises and challenges. Rapid Prototype J 19(5):353–364

Zhang D et al (2016) Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth Met 217:79–86

Farahani RD, Dubé M, Therriault D (2016) Three-dimensional printing of multifunctional nanocomposites: manufacturing techniques and applications. Adv. Mater. 28:5794–5821

Utela B, Storti D, Anderson R, Ganter M (2008) A review of process development steps for new material systems in three dimensional printing (3DP). J Manuf Process 10(2):96–104

Gnanasekaran K et al (2017) 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl Mater Today 9:21–28

Lamberti P et al (2018) Evaluation of thermal and electrical conductivity of carbon-based PLA nanocomposites for 3D printing. AIP Conf Proc 1981:3–7

Wei X et al (2015) 3D printable graphene composite. Sci Rep 5:11181. https://doi.org/10.1038/srep11181

Fu S, Sun Z, Huang P, Li Y, Hu N (2019) Some basic aspects of polymer nanocomposites: a critical review. Nano Mater Sci 1(1):2–30

Galindo B, Alcolea SG, Gómez J, Navas A, Murguialday AO, Fernandez MP, Puelles RC (2014) Effect of the number of layers of graphene on the electrical properties of TPU polymers. IOP Conf Ser Mater Sci Eng 64:12008. https://doi.org/10.1088/1757-899X/64/1/012008

Eigler S, Grimm S, Enzelberger-Heim M, Müller P, Hirsch A (2013) Graphene oxide: efficiency of reducing agents. Chem Commun 49(67):7391

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39(1):228–240

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80(6):1339

Gómez J, Villaro E, Navas A, Recio I (2017) Testing the influence of the temperature, RH and filler type and content on the universal power law for new reduced graphene oxide TPU composites. Mater Res Express 4(10):105020

Gomez J, Recio I, Navas A, Villaro E, Galindo B, Ortega Murguialday A (2019) Processing influence on dielectric, mechanical and electrical properties of reduced graphene oxide-TPU nanocomposites. J. Appl. Polym. Sci. 136:47220

Chee SY, Poh HL, Chua CK, Sanek F, Sofer Z, Pumera M (2012) Influence of parent graphite particle size on the electrochemistry of thermally reduced graphene oxide. Phys Chem Chem Phys 14(37):12794–12799

Pan S, Aksay IA (2011) Factors controlling the size of graphene oxide sheets produced via the graphite oxide route. ACS Nano 5(5):4073–4083

Ambrosetti G, Grimaldi C, Balberg I, Maeder T, Danani A, Ryser P (2010) Solution of the tunneling-percolation problem in the nanocomposite regime. Phys Rev B Condens Matter Mater Phys 81(15):1–12

Zhang R, Zhang B, Sun S (2015) Preparation of high-quality graphene with a large-size by sonication-free liquid-phase exfoliation of graphite with a new mechanism. RSC Adv 5(56):44783–44791

JabariSeresht R, Jahanshahi M, Rashidi A, Ghoreyshi AA (2013) Synthesize and characterization of graphene nanosheets with high surface area and nano-porous structure. Appl Surf Sci 276:672–681

Cui P, Lee J, Hwang E, Lee H (2011) One-pot reduction of graphene oxide at subzero temperatures. Chem Commun 47(45):12370–12372

Joya MR, Gonzalez JD, Barba-Ortega J (2014) Raman spectroscopy as a versatile tool for studying of explicit contribution of anharmonicity. J Nonlinear Opt Phys Mater 23(4):235

King AAK et al (2016) A new raman metric for the characterisation of graphene oxide and its derivatives. Sci Rep 6:1–6

Bokobza L (2017) Spectroscopic techniques for the characterization of polymer nanocomposites: a review. Polymers (Basel) 10(1):7

Kister G, Cassanas G, Vert M, Pauvert B, Tbol A (1995) Vibrational analysis of poly(L-lactic acid). J Raman Spectrosc 26:307–311

Casiraghi C, Pisana S, Novoselov KS, Geim AK, Ferrari AC (2007) Raman fingerprint of charged impurities in graphene. Appl Phys Lett 91:233108. https://doi.org/10.1063/1.2818692

Tong XZ, Song F, Li MQ, Wang XL, Chin IJ, Wang YZ (2013) Fabrication of graphene/polylactide nanocomposites with improved properties. Compos Sci Technol 88:33–38

Yang JH, Lin SH, Der Lee Y (2012) Preparation and characterization of poly(l-lactide)-graphene composites using the in situ ring-opening polymerization of PLLA with graphene as the initiator. J Mater Chem 22(21):10805–10815

Sabzi M, Jiang L, Liu F, Ghasemi I, Atai M (2013) Graphene nanoplatelets as poly(lactic acid) modifier: linear rheological behavior and electrical conductivity. J Mater Chem A 1(28):8253–8261

Ivanov E et al (2019) PLA/graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl Sci 9(6):1209

Author information

Authors and Affiliations

Contributions

EV was preparing and characterizing PLA-rGO composites and originally writing the paper. JP is responsible for device preparation and characterization. JG is responsible for the conceptualization, supervision, methodology and reviewing the article. BAH project management, reviewing, and proofreading the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gomez, J., Villaro, E., Perez, J. et al. Preparation of electrically conductive PLA/rGO nanocomposite filaments. Graphene Technol 5, 41–48 (2020). https://doi.org/10.1007/s41127-020-00031-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41127-020-00031-3