Abstract

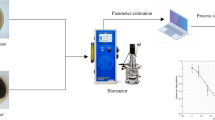

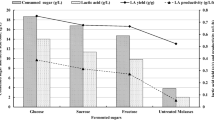

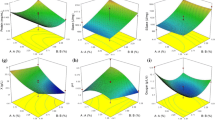

The current study aimed to model using various primary models the Aspergillus niger inulinase fermentation in the sugar-beet molasses-based medium, validate the selected functions, and analyze in terms of sensitivity the selected functions. In the selection of models, model comparisons including root-mean-square-error, mean-absolute-error, mean-standard-deviation, determination coefficient, slope, Akaike Information Criterion, bias factor, accuracy factor, and f-testing were used. The results indicated that the best models were Morgan-Mercer-Flodin and Cone for sugar consumption, Stannard, Morgan-Mercer-Flodin, Fitzhugh, and Cone for inulinase production (I), modified Gompertz and Richards for invertase-type production (S), Weibull for S/I ratio, modified Richards and Asymmetric for specific inulinase production, and Asymmetric for specific invertase-type production. By using an independent set of the experimental data, the validation of the selected models gave gratifying results with a high determination coefficient (> 0.968). According to the sensitivity analysis made by increasing or decreasing each parameter in the selected models by 5%, satisfactory results with a high determination coefficient were also yielded in both situations. But with a 5% rise in each parameter of the selected models, higher product formation and higher production and consumption rates are predicted to be achieved. Overall, the results showed that the selected models can serve as universal equations for describing A. niger inulinase fermentation.

Similar content being viewed by others

References

Singh R, Chauhan K, Pandey A, Larroche C (2018) Biocatalytic strategies for the production of high fructose syrup from inulin. Bioresour Technol 260:395–403

Shoaib M, Shehzad A, Omar M, Rakha A, Raza H, Sharif HR, Shakeel A, Ansari A, Niazi S (2016) Inulin: Properties, health benefits and food applications. Carbohydr Polym 147:444–454

Das D, Bhat R, Selvaraj R (2019) Review of inulinase production using solid-state fermentation. Ann Microbiol 69(3):201–209

Singh RS, Chauhan K (2017) Inulinase production from a new inulinase producer, Penicillium oxalicum BGPUP-4. Biocatal Agric Biotechnol 9:1-10

Singh RS, Chauhan K (2018) Production, purification, characterization and applications of fungal inulinases. Curr Biotechnol 7(3):242–260

Mavituna F, Sinclair CG (2008) Modelling the kinetics of biological activity in fermentation systems. In: Practical Fermentation Technology. John Wiley & Sons Ltd Chichester, UK, pp 167–230

Türker M (2005) Matematiksel modellemenin temel ilkeleri. In: Türker M (ed) Biyoreaksiyon Mühendisliği: Biyolojik Proseslerin Kinetiği ve Modellenmesi. Su Vakfı Yayınları, İstanbul, pp 65–81

Baranyi J, Roberts TA (1994) A dynamic approach to predicting bacterial growth in food. Int J Food Microbiol 23(3–4):277–294

Cone JW, van Gelder AH, Visscher GJ, Oudshoorn L (1996) Influence of rumen fluid and substrate concentration on fermentation kinetics measured with a fully automated time related gas production apparatus. Anim Feed Sci Technol 61(1):113–128

Dantigny P, Nanguy SP-M, Judet-Correia D, Bensoussan M (2011) A new model for germination of fungi. Int J Food Microbiol 146(2):176–181

Fitzhugh H (1976) Analysis of growth curves and strategies for altering their shape. J Anim Sci 42(4):1036–1051

Huang L (2013) Optimization of a new mathematical model for bacterial growth. Food Control 32(1):283–288

Morgan PH, Mercer LP, Flodin NW (1975) General model for nutritional responses of higher organisms. Proc Natl Acad Sci 72(11):4327–4331

Stannard C, Williams A, Gibbs P (1985) Temperature/growth relationships for psychrotrophic food-spoilage bacteria. Food Microbiol 2(2):115–122

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18(3):293–297

Zwietering M, Jongenburger I, Rombouts F, Van’t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56(6):1875–1881

Germec M, Turhan I (2020) Enhanced production of Aspergillus niger inulinase from sugar beet molasses and its kinetic modeling. Biotechnol Lett 42(10):1939–1955

Germec M, Turhan I (2019) Evaluation of carbon sources for the production of inulinase by Aspergillus niger A42 and its characterization. Bioprocess Biosyst Eng 42:1993–2005

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1):248–254

Germec M, Gürler HN, Ozcan A, Erkan SB, Karahalil E, Turhan I (2020) Medium optimization and kinetic modeling for the production of Aspergillus niger inulinase. Bioprocess Biosyst Eng 43(2):217–232

Ross T (1996) Indices for performance evaluation of predictive models in food microbiology. J Appl Microbiol 81(5):501–508

Cheng K-C, Demirci A, Catchmark JM, Puri VM (2010) Modeling of pullulan fermentation by using a color variant strain of Aureobasidium pullulans. J Food Eng 98(3):353–359

Akaike H (1974) A new look at the statistical model identification. IEEE Trans Automat Contr 19(6):716–723

Germec M, Turhan I (2021) Predicting the experimental data of the substrate specificity of Aspergillus niger inulinase using mathematical models, estimating kinetic constants in the Michaelis-Menten equation, and sensitivity analysis. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01830-1

Shinto H, Tashiro Y, Yamashita M, Kobayashi G, Sekiguchi T, Hanai T, Kuriya Y, Okamoto M, Sonomoto K (2007) Kinetic modeling and sensitivity analysis of acetone–butanol–ethanol production. J Biotechnol 131(1):45–56

Germec M, Ozcan A, Turhan I (2019) Bioconversion of wheat bran into high value-added products and modelling of fermentations. Ind Crops Prod 139:111565

Gürler HN, Germec M, Turhan I (2020) The inhibition effect of phenol on the production of Aspergillus niger inulinase and its modeling. Journal of Food Processing and Preservation:e14522

Ilgın M, Germec M, Turhan I (2020) Inulinase production and mathematical modeling from carob extract by using Aspergillus niger. Biotechnol Prog 36 (1):e2919

Yatmaz E, Germec M, Erkan SB, Turhan I (2020) Modeling of ethanol fermentation from carob extract–based medium by using Saccharomyces cerevisiae in the immobilized-cell stirred tank bioreactor. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-01154-6

Funding

This work was supported by the Akdeniz University Research Foundation [Grant number #FDK-2019–4761].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Germec, M., Turhan, I. Application of Aspergillus niger inulinase production in sugar beet molasses-based medium optimized by Central Composite Design to mathematical models. Biomass Conv. Bioref. 13, 10985–11003 (2023). https://doi.org/10.1007/s13399-021-01923-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01923-x