Abstract

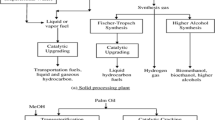

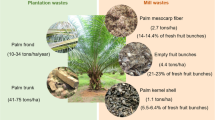

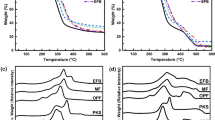

The objective of this work is to evaluate the potential of oil palm biomass (OPB) in terms of physicochemical properties for producing biofuels via pyrolysis processes. The OPB included oil palm trunk (OPT), oil palm fronds (OPF), oil palm shell (OPS), oil palm roots (OPR), oil palm decanter cake (OPDC), empty fruit bunches (EFB), oil palm fiber (OPFB), and oil palm sewage sludge (OPSS). Their physicochemical properties are considered on several physical, chemical, and thermal aspects. The results showed that particle size distribution and bulk density of ground OPB were different. The proximate analysis results of OPB were consistent with the lignocellulose content and extractives. The carbon and hydrogen content of the OPB were also correlated with the organic components. Some OPB contained high lignin and extractives. The lignin content of OPB strongly influenced to thermal decomposition trend. OPB contained high inorganic elements such as potassium (K), calcium (C), and iron (Fe). The higher heating value and potential use as energy equivalent with fossil fuels of the OPB were relatively low. OPB had low thermal conductivity, and the dielectric constant, loss factor, and tangent loss of the OPB were also low. Thus, these results will be beneficial for the researchers and biofuel producers for choosing the appropriate OPB, as well as the operating conditions and reactor types.

Similar content being viewed by others

References

Abuelnuor AAA, Wahid MA, Hosseini SE et al (2014) Characteristics of biomass in flameless combustion: a review. Renew Sust Energ Rev 33:363–370. https://doi.org/10.1016/j.rser.2014.01.079

Demirbaş A (2001) Relationships between lignin contents and heating values of biomass. Energy Convers Manag 42:183–188

Tanger P, Field JL, Jahn CE et al (2013) Biomass for thermochemical conversion: targets and challenges. Front Plant Sci 4:218. https://doi.org/10.3389/fpls.2013.00218

Yelmen B, Tarık Çakir M (2016) Biomass potential of Turkey and energy production applications. Energy Sources, Part B Econ Planning, Policy 11:428–435. https://doi.org/10.1080/15567249.2011.613443

British petroleum (2017) BP statistical review of world energy. BP p.l.c. 2017. https://euagenda.eu/upload/publications/untitled-96772-ea/. Accessed 26 June 2019

Mishra RK, Mohanty K (2019) Pyrolysis characteristics, fuel properties, and compositional study of Madhuca longifolia seeds over metal oxide catalysts. Biomass Convers Biorefinery:1–17. https://doi.org/10.1007/s13399-019-00469-3

Abbasi T, Abbasi SA (2010) Biomass energy and the environmental impacts associated with its production and utilization. Renew Sust Energ Rev 14:919–937. https://doi.org/10.1016/j.rser.2009.11.006

Laser M, Lynd LR (2014) Comparative efficiency and driving range of light- and heavy-duty vehicles powered with biomass energy stored in liquid fuels or batteries. Proc Natl Acad Sci 111:3360–3364. https://doi.org/10.1073/pnas.1314039111

Khosravanipour Mostafazadeh A, Solomatnikova O, Drogui P, Tyagi RD (2018) A review of recent research and developments in fast pyrolysis and bio-oil upgrading. Biomass Convers Biorefinery 8:739–773. https://doi.org/10.1007/s13399-018-0320-z

Fernando AL, Duarte MP, Almeida J, Boléo S, Mendes B (2010) Environmental impact assessment of energy crops cultivation in Europe. Biofuels Bioprod Biorefin 4:594–604. https://doi.org/10.1002/bbb.249

Jagustyn B, Patyna I, Skawińska A (2013) Evaluation of physicochemical properties of palm kernel shell as agro biomass used in the energy industry. Chemik 67:552–559

Preechajarn S, Prasertsri P (2018) Thailand biofuels annual. USDA foreign agricultural service. https://www.biofuelsdigest.com/bdigest/tag/thailand/thaibiofuelsannual2018. Accessed 2 July 2019

Hosseini SE, Wahid MA, Ganjehkaviri A (2015) An overview of renewable hydrogen production from thermochemical process of oil palm solid waste in Malaysia. Energy Convers Manag 94:415–429. https://doi.org/10.1016/j.enconman.2015.02.012

Asadullah M, Ab Rasid NS, Kadir SASA, Azdarpour A (2013) Production and detailed characterization of bio-oil from fast pyrolysis of palm kernel shell. Biomass Bioenergy 59:316–324. https://doi.org/10.1016/j.biombioe.2013.08.037

Prasertsan S, Presertsan P (1996) Biomass residues from palm oil mills in Thailand: an overview on quantity and potential usage. Biomass Bioenergy 11:387–395. https://doi.org/10.1016/S0961-9534(96)00034-7

Kurnia JC, Jangam SV, Akhtar S, Sasmito AP, Mujumdar AS (2016) Prolysis advances in biofuel from oil palm and palm oil processing waste: a review. Biofuel res. J. 9:332–346. https://doi.org/10.18331/BRJ2016.3.1.3

Loh SK (2017) The potential of the Malaysian OPB as a renewable energy source. Energy Convers Manag 141:285–298

Iskandar MJ, Baharum A, Anuar FH, Othaman R (2018) Palm oil industry in South East Asia and the effluent treatment technology—a review. Environ Technol Innov 9:169–185. https://doi.org/10.1016/j.eti.2017.11.003

Areerat K (2006) Appropriate technology evaluation for oil palm by-products utilization in Krabi province. Dissertation, Mahidol University

Papong S, Yuvaniyama C, Lohsomboon P, Malakul P (2004) Overview of biomass utilization in Thailand. In: ASEAN Biomass Meeting, Bangkok, pp 1–10

IRENA (2015) A background paper to renewable energy in manufacturing. https://www.irena.org/publications/2014/Jun/Renewable-Energy-in-Manufacturing. Accessed 2 July 2019

Shuit SH, Tan KT, Lee KT, Kamaruddin AH (2009) OPB as a sustainable energy source: a Malaysian case study. Energy 34:1225–1235. https://doi.org/10.1016/j.energy.2009.05.008

Mckendry P (2002) Energy production from biomass (part 2): conversion technologies. Bioresour Technol 83:47–54. https://doi.org/10.1016/S0960-8524(01)00119-5

Velghe I, Carleer R, Yperman J, Schreurs S (2011) Study of the pyrolysis of municipal solid waste for the production of valuable products. J Anal Appl Pyrolysis 92:366–375. https://doi.org/10.1016/j.jaap.2011.07.011

Bridgwater AV, Peacocke GVC (2000) Fast pyrolysis processes for biomass. Renew Sust Energ Rev 4:1–73

Yaman S (2004) Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers Manag 45:651–671. https://doi.org/10.1016/S0196-8904(03)00177-8

Şensöz S, Can M (2002) Pyrolysis of pine ( Pinus Brutia ten.) chips: 1. effect of pyrolysis temperature and heating rate on the product yields. Energy Sources 24:347–355. https://doi.org/10.1080/00908310252888727

Shastri Y, Hansen A, Rodríguez L, Ting KC (2014) Engineering and science of biomass feedstock production and provision. Springer Science + Business media, New York

Lozano-García B, Parras-Alcántara L (2013) Short-term effects of olive mill by-products on soil organic carbon, total N, C: N ratio and stratification ratios in a Mediterranean olive grove. Agric Ecosyst Environ 165:68–73

Bridgwater AV (1999) Principles and practice of biomass fast pyrolysis processes for liquids. J Anal Appl Pyrolysis 51:3–22

Meier D, Faix, O (1999) State of the art of applied fast pyrolysis of lignocellulosic materials-a review. Bioresour Technol 68, 71–77. https://doi.org/10.1016/S0960-8524(98)00086-8

Bridgwater AV (2012) Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 38:68–94. https://doi.org/10.1016/j.biombioe.2011.01.048

Isahak WNRW, Hisham MWM, Yarmo MA, Yun Hin T (2012) A review on bio-oil production from biomass by using pyrolysis method. Renew Sust Energ Rev 16:5910–5923. https://doi.org/10.1016/j.rser.2012.05.039

Fonts I, Gea G, Azuara M, Ábrego J, Arauzo J (2012) Sewage sludge pyrolysis for liquid production: a review. Renew Sust Energ Rev 16:2781–2805. https://doi.org/10.1016/j.rser.2012.02.070

Sirijanusorn S, Sriprateep K, Pattiya A (2013) Pyrolysis of cassava rhizome in a counter-rotating twin screw reactor unit. Bioresour Technol 139:343–348

Alvarez J, Amutio M, Lopez G, Bilbao J, Olazar M (2015) Fast co-pyrolysis of sewage sludge and lignocellulosic biomass in a conical spouted bed reactor. Fuel 159:810–818

Huang X, Cao J-P, Zhao X-Y et al (2016) Pyrolysis kinetics of soybean straw using thermogravimetric analysis. Fuel 169:93–98. https://doi.org/10.1016/j.fuel.2015.12.011

Wang Y, Zeng Z, Tian X, Dai L, Jiang L, Zhang S, Wu Q, Wen P, Fu G, Liu Y, Ruan R (2018) Production of bio-oil from agricultural waste by using a continuous fast microwave pyrolysis system. Bioresour Technol 269:162–168

Leng L, Huang H (2018) An overview of the effect of pyrolysis process parameters on biochar stability. Bioresour Technol 270:627–642

Chen X, Li S, Liu Z, Chen Y, Yang H, Wang X, Che Q, Chen W, Chen H (2019) Pyrolysis characteristics of lignocellulosic biomass components in the presence of CaO. Bioresour Technol 287:21493

Pattiya A (2011) Bio-oil production via fast pyrolysis of biomass residues from cassava plants in a fluidised-bed reactor. Bioresour Technol 102:1959–1967

Pattiya A, Suttibak S (2012a) Influence of a glass wool hot vapour filter on yields and properties of bio-oil derived from rapid pyrolysis of paddy residues. Bioresour Technol 116:107–113

Kim SS, Ly HV, Kim J, Choi JH, Woo HC (2013) Thermogravimetric characteristics and pyrolysis kinetics of alga Sagarssum sp. biomass. Bioresour Technol 139:242–248

Kelkar S, Saffron CM, Chai L et al (2015) Pyrolysis of spent coffee grounds using a screw-conveyor reactor. Fuel process Technol 137:170–178. https://doi.org/10.1016/j.fuproc.2015.04.006

Biswas B, Pandey N, Bisht Y, Singh R, Kumar J, Bhaskar T (2017) Pyrolysis of agricultural biomass residues: comparative study of corn cob, wheat straw, rice straw and rice husk. Bioresour Technol 237:57–63

Fiore S, Berruti F, Briens C (2018) Investigation of innovative and conventional pyrolysis of ligneous and herbaceous biomasses for biochar production. Biomass Bioenergy 119:381–391. https://doi.org/10.1016/j.biombioe.2018.10.010

Ani FN, Zailani R (1997) Characteristics of pyrolysis oil and char from oil Palm shells. Dev. Thermochem. Biomass convers. Springer Netherlands, Dordrecht, pp 425–432. https://doi.org/10.1007/978-94-009-1559-6_33

Okoroigwe E, Li Z, Stuecken T, Saffron C, Onyegegbu S (2012) Pyrolysis of Gmelina arborea wood for bio-oil/bio-char production: physical and chemical characterisation of products. J Appl Sci. https://doi.org/10.3923/jas.2012.369.374

Saidur R, Abdelaziz EA, Demirbas A, Hossain MS, Mekhilef S (2011) A review on biomass as a fuel for boilers. Renew. Sustain. Energy rev. 15:2262–2289. https://doi.org/10.1016/j.rser.2011.02.015

Acda MN (2016) Physical and chemical properties of fuel pellets from agricultural residues. Former Philipp Agric 99:283–287

Abdullah NA, Mohamed R, Mahmood WMFW, Saad MHM (2017) Black smoke elimination via PID controlled co-firing technique at palm oil mill. Int J Appl Eng Res 12:8050–8056

Salema AA, Ani FN (2011) Microwave induced pyrolysis of OPB. Bioresour Technol 102:3388–3395

Omar R, Idris A, Yunus R, Khalid K, Isma MIA (2011) Characterization of empty fruit bunch for microwave-assisted pyrolysis. Fuel 90:1536–1544

Ruengvilairat P, Tanatavikorn H, Vitidsant T (2012) Bio-oil production by pyrolysis of oil palm empty fruit bunch in nitrogen and steam atmospheres. J Sustain Bioenergy Syst 2:75

Kabir G, Mohd Din AT, Hameed BH (2017) Pyrolysis of oil palm mesocarp fiber and palm frond in a slow-heating fixed-bed reactor: a comparative study. Bioresour Technol 241:563–572

Sukiran MA, Loh SK, Bakar NA (2016) Production of bio-oil from fast pyrolysis of oil palm biomass using fluidised bed reactor. J Energy Technol Policy 6:52–62

Yakub MI, Abdalla AY, Feroz KK, Suzana Y, Ibraheem A, Chin SA (2015) Pyrolysis of oil palm residues in a fixed bed tubular reactor. Journal of Power and Energy Engineering 3:185–193

Sareekam N, Kamarudin SK, Kasmuri NH (2016) Optimization of bio oil from palm oil fronds via fast pyrolysis. Indian J Sci Technol 9:1–13

Bensidhom G, Hassen-Trabelsia AB, Alper K, Sghairoun M, Zaafouri K, Trabelsi I (2018) Pyrolysis of date palm waste in a fixed-bed reactor: characterization of pyrolytic products. Bioresour Technol 247:363–369

Annamalai K, Sweeten JM, Ramalingam SC (1987) Technical notes: estimation of gross heating values of biomass fuels. Trans ASAE 30:1205–1208

Parikh J, Channiwala S, Ghosal G (2005) A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 84:487–494. https://doi.org/10.1016/j.fuel.2004.10.010

Sheng C, Azevedo JLT (2005) Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 28:499–507

Demirbaş A (2001) Relationships between lignin contents and heating values of biomass. Energy Convers Manag 42:183–188

Goering HK, Van Soest PJ (1970) Forage fiber analysis, apparatus, reagents, procedures, and some applications. In: Agriculture handbook, vol. 379. ARS-USDA, Washington, DC

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Reza MT, Uddin MH, Lynam JG, Hoekman SK, Coronella CJ (2014) Hydrothermal carbonization of loblolly pine: reaction chemistry and water balance. Biomass Convers Biorefinery 4:311–321. https://doi.org/10.1007/s13399-014-0115-9

Kambo HS, Dutta A (2015) Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers Manag 105:746–755. https://doi.org/10.1016/j.enconman.2015.08.031

Salema AA, Yeow YK, Ishaque K et al (2013) Dielectric properties and microwave heating of oil palm biomass and biochar. Ind Crop Prod 50:366–374. https://doi.org/10.1016/j.indcrop.2013.08.007

Pattiya A, Suttibak S (2012) Production of bio-oil via fast pyrolysis of agricultural residues from cassava plantations in a fluidised-bed reactor with a hot vapour filtration unit. J Anal Appl Pyrolysis 95:227–235

Duong TL, Nguyen DT, Nguyen HHM, Phan BMQ, Nguyen HL, Huynh TM (2019) Fast pyrolysis of Vietnamese waste biomass: relationship between biomass composition, reaction conditions, and pyrolysis products, and a strategy to use a biomass mixture as feedstock for bio-oil production. J Mater Cycles Waste Manag 21:624–632

Sirijanusorn S, Sriprateep K, Pattiya A (2013) Pyrolysis of cassava rhizome in a counter-rotating twin screw reactor unit. Bioresour Technol 139:343–348. https://doi.org/10.1016/j.biortech.2013.04.024

Scott DS, Piskorz J (1984) The continuous flash pyrolysis of biomass. Can J Chem Eng 62:404–412. https://doi.org/10.1002/cjce.5450620319

McKendry P (2002) Energy production from biomass (part 1): overview of biomass. Bioresour Technol 83:37–46

Brar JS, Singh K, Wang J, Kumar S (2012) Cogasification of coal and biomass: a review. Int J For Res 2012:1–10. https://doi.org/10.1155/2012/363058

Elliott DC, Hart TR, Neuenschwander GG, Rotness LJ, Olarte MV, Zacher AH (2012) Catalytic hydroprocessing of fast pyrolysis bio-oil from pine sawdust. Energy and Fuels 26:3891–3896. https://doi.org/10.1021/ef3004587

Okoroigwe EC, Saffron CM (2012) Determination of bio-energy potential of palm kernel shell by physicochemical characterization. Niger J Technol 31:329–335

Kang B-S, Lee KH, Park HJ, Park Y-K, Kim J-S (2006) Fast pyrolysis of radiata pine in a bench scale plant with a fluidized bed: influence of a char separation system and reaction conditions on the production of bio-oil. J Anal Appl Pyrolysis 76:32–37

Lu Q, Li W-Z, Zhu X-F (2009) Overview of fuel properties of biomass fast pyrolysis oils. Energy Convers Manag 50:1376–1383

Amutio M, Lopez G, Alvarez J, Olazar M, Bilbao J (2015) Fast pyrolysis of eucalyptus waste in a conical spouted bed reactor. Bioresour Technol 194:225–232

Inguanzo M, Domınguez A, Menéndez JA, Blanco CG, Pis JJ (2002) On the pyrolysis of sewage sludge: the influence of pyrolysis conditions on solid, liquid and gas fractions. J Anal Appl Pyrolysis 63:209–222

Domínguez A, Menéndez JA, Inguanzo M, Pis JJ (2006) Production of bio-fuels by high temperature pyrolysis of sewage sludge using conventional and microwave heating. Bioresour Technol 97:1185–1193

Sukiran MA, Loh SK, Bakar NA (2016) Production of bio-oil from fast pyrolysis of OPB using fluidised bed reactor. J Energy Technol Policy 6:52–62

Maddi B, Viamajala S, Varanasi S (2011) Comparative study of pyrolysis of algal biomass from natural lake blooms with lignocellulosic biomass. Bioresour Technol 102:11018–11026

Chaiwong K, Kiatsiriroat T, Vorayos N, Thararax C (2013) Study of bio-oil and bio-char production from algae by slow pyrolysis. Biomass Bioenergy 56:600–606

Pimenidou P, Dupont V (2012) Characterisation of palm empty fruit bunch (PEFB) and pinewood bio-oils and kinetics of their thermal degradation. Bioresour Technol 109:198–205

De Bari I, Barisano D, Cardinale M, Matera D, Nanna F, Viggiano D (2000) Air gasification of biomass in a downdraft fixed bed: a comparative study of the inorganic and organic products distribution. Energy Fuel 14:889–898. https://doi.org/10.1021/ef990243g

Berndes G, Börjesson P, Ostwald M, Palm M (2008) Multifunctional biomass production systems–an overview with presentation of specific applications in India and Sweden. Biofuels, Bioprod Biorefining Innov a Sustain Econ 2:16–25

Wei X, Schnell U, Hein K (2005) Behaviour of gaseous chlorine and alkali metals during biomass thermal utilisation. Fuel 84:841–848. https://doi.org/10.1016/j.fuel.2004.11.022

Ninduangdee P, Kuprianov VI (2014) Combustion of palm kernel shell in a fluidized bed: optimization of biomass particle size and operating conditions. Energy Convers Manag 85:800–808

Eom I-Y, Kim J-Y, Kim T-S, Lee S-M, Choi D, Choi I-G (2012) Effect of essential inorganic metals on primary thermal degradation of lignocellulosic biomass. Bioresour Technol 104:687–694

Zabeti M, Nguyen TS, Lefferts L, Heeres HJ, Seshan K (2012) In situ catalytic pyrolysis of lignocellulose using alkali-modified amorphous silica alumina. Bioresour Technol 118:374–381

Zhang W, Yuan C, Xu J, Yang X (2015) Beneficial synergetic effect on gas production during co-pyrolysis of sewage sludge and biomass in a vacuum reactor. Bioresour Technol 183:255–258

Zuo W, Jin B, Huang Y, Sun Y (2014) Characterization of top phase oil obtained from co-pyrolysis of sewage sludge and poplar sawdust. Environ Sci Pollut Res 21:9717–9726

Akhtar J, Amin NS (2012) A review on operating parameters for optimum liquid oil yield in biomass pyrolysis. Renew Sust Energ Rev 16:5101–5109

Quan C, Gao N, Song Q (2016) Pyrolysis of biomass components in a TGA and a fixed-bed reactor: thermochemical behaviors, kinetics, and product characterization. J Anal Appl Pyrolysis 121:84–92

Qu X, Liang P, Wang Z, Zhang R, Sun D, Gong X (2011) Pilot development of polygeneration process of circulating fluidized bed combustion combined with coal pyrolysis. Chem Eng Technol 34:61–68

Klass DL (1988) The US biofuels industry. Institute of Gas Technology, Chicago

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Michailof CM, Pilavachi PA, Lappas AA (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrolysis 105:143–150

Chang G, Miao P, Yan X, Wang G, Guo Q (2018) Phenol preparation from catalytic pyrolysis of palm kernel shell at low temperatures. Bioresour Technol 253:214–219

Dhyani V, Bhaskar T (2018) Chapter 2: kinetic analysis of biomass pyrolysis. In: Waste biorefinery. Elsevier, London

Cai J, He Y, Yu X, Banks SW, Yang Y, Zhang X (2017) Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew Sust Energ Rev 76:309–322

Mason PE, Darvell LI, Jones JM, Williams A (2016) Comparative study of the thermal conductivity of solid biomass fuels. Energy Fuel 30:2158–2163

Gupta M, Yang J, Roy C (2003) Specific heat and thermal conductivity of softwood bark and softwood char particles☆. Fuel 82:919–927

Hayhurst AN (2013) The kinetics of the pyrolysis or devolatilisation of sewage sludge and other solid fuels. Combust Flame 160:138–144

Jones JM, Saddawi A, Dooley B, Mitchell EJS, Werner J, Waldron DJ (2015) Low temperature ignition of biomass. Fuel Process Technol 134:372–377

Huang Y-F, Chiueh P-T, Lo S-L (2016) A review on microwave pyrolysis of lignocellulosic biomass. Sustain Environ Res 26:103–109

Yin C (2012) Microwave-assisted pyrolysis of biomass for liquid biofuels production. Bioresour Technol 120:273–284

Lam SS, Chase HA (2012) A review on waste to energy processes using microwave pyrolysis. Energies 5:4209–4232

Menéndez JA, Arenillas A, Fidalgo B, Fernández Y, Zubizarreta L, Calvo EG (2010) Microwave heating processes involving carbon materials. Fuel Process Technol 91:1–8. https://doi.org/10.1016/j.fuproc.2009.08.021

Robinson J, Dodds C, Stavrinides A, Kingman S, Katrib J, Wu Z (2015) Microwave pyrolysis of biomass: control of process parameters for high pyrolysis oil yields and enhanced oil quality. Energy Fuel 29:1701–1709

Acknowledgments

The authors express their sincere appreciation to Energy Conservation Promotion Fund, Energy Policy and Planning Office (EPPO), Ministry of Energy of Thailand.

Funding

This study was also supported by Thailand Research Fund (Contract number: MRG6280084), Prince of Songkla University (Contract number: RDO610037S), Graduate School, Prince of Songkla University, and Interdisciplinary Graduate School of Energy systems, Prince of Songkla University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shrivastava, P., Khongphakdi, P., Palamanit, A. et al. Investigation of physicochemical properties of oil palm biomass for evaluating potential of biofuels production via pyrolysis processes. Biomass Conv. Bioref. 11, 1987–2001 (2021). https://doi.org/10.1007/s13399-019-00596-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00596-x