Abstract

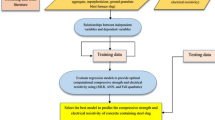

Due to increased industrialization, large amount of industrial by-products are produced every year in all parts of the world. Disposal of these often toxic wastes is the major problem faced and can potentially be solved by their use in the construction industry. The main aim of this study was to utilize the argon oxygen decarburization (AOD) steel slag (a waste product from the stainless steel industry) in the concrete mix for construction of rigid pavements. The present study evaluated various properties of concrete mixes containing 0–25% of AOD steel slag as a partial replacement of ordinary portland cement and further curing the mixes for 28, 90, 180 and 365 days. Thus, the study investigated the compressive and flexural strengths, abrasion resistance, resistance to acid attack and resistance to sulfate attack of concrete mixes. Further, scanning electron microscope, energy-dispersive X-ray spectroscopy and toxicity characteristic leaching potential (TCLP) analyses were also conducted to study the micro-structural properties and leaching characteristics of steel slag mixed concrete. Compressive and flexural strength showed the positive results as the curing period of the specimens increased. Durability properties were less affected by the addition of AOD steel slag. TCLP analysis revealed that the toxicity of steel slag concrete was found within the permissible limits as compared to the raw steel slag. Further, to approximate the underlying relationship existing between the input–output data, a Legendre functional link neural network has been implemented for the prediction of compressive and flexural strengths.

Similar content being viewed by others

References

Sheen, Y.-N.; Le, D.-H.; Sun, T.-H.: Innovative usages of stainless steel slags in developing self-compacting concrete. Constr. Build. Mater. 101, 268–276 (2015)

Zhao, H.; Qi, Y.; Shi, Y.; Na, X.; Feng, H.: Mechanism and prevention of disintegration of aod stainless steel slag. J. Iron Steel Res. Int. 20(4), 26–30 (2013)

Adegoloye, G.; Beaucour, A.-L.; Ortola, S.; Noumowé, A.: Concretes made of eaf slag and aod slag aggregates from stainless steel process: mechanical properties and durability. Constr. Build. Mater. 76, 313–321 (2015)

Shen, H.; Forssberg, E.; Nordström, U.: Physicochemical and mineralogical properties of stainless steel slags oriented to metal recovery. Resour. Conserv. Recycl. 40(3), 245–271 (2004)

Baciocchi, R.; Costa, G.; Polettini, A.; Pomi, R.: Influence of particle size on the carbonation of stainless steel slag for co2 storage. Energy Procedia 1(1), 4859–4866 (2009)

Huaiwei, Z.; Xin, H.: An overview for the utilization of wastes from stainless steel industries. Resour. Conserv. Recycl. 55(8), 745–754 (2011)

Salman, M.; Cizer, Ö.; Pontikes, Y.; Snellings, R.; Dijkman, J.; Sels, B.; Vandewalle, L.; Blanpain, B.; Van Balen, K.: Alkali activation of aod stainless steel slag under steam curing conditions. J. Am. Ceram. Soc. 98(10), 3062–3074 (2015)

Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E.: Acid resistance and durability properties of steel fiber-reinforced concrete incorporating rice husk ash and recycled aggregate. Constr. Build. Mater. 202, 266–275 (2019)

Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.: Environmental impact of cement production: detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 18(5), 478–485 (2010)

van Deventer, J.S.; Provis, J.L.; Duxson, P.; Brice, D.G.: Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valoriz. 1(1), 145–155 (2010)

Mehta, P.K.: Greening of the concrete industry for sustainable development. Concr. Int. 24(7), 23–28 (2002)

Khotbehsara, M.M.; Mohseni, E.; Yazdi, M.A.; Sarker, P.; Ranjbar, M.M.: Effect of nano-cuo and fly ash on the properties of self-compacting mortar. Constr. Build. Mater. 94, 758–766 (2015)

Mohseni, E.; Ranjbar, M.M.; Yazdi, M.A.; Hosseiny, S.S.; Roshandel, E.: The effects of silicon dioxide, iron (iii) oxide and copper oxide nanomaterials on the properties of self-compacting mortar containing fly ash. Mag. Concr. Res. 67(20), 1112–1124 (2015)

Elahi, A.; Basheer, P.; Nanukuttan, S.; Khan, Q.: Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 24(3), 292–299 (2010)

Xiang, X.; Xi, J.; Li, C.; Jiang, X.: Preparation and application of the cement-free steel slag cementitious material. Constr. Build. Mater. 114, 874–879 (2016)

Autelitano, F.; Giuliani, F.: Electric arc furnace slags in cement-treated materials for road construction: mechanical and durability properties. Constr. Build. Mater. 113, 280–289 (2016)

Rondi, L.; Bregoli, G.; Sorlini, S.; Cominoli, L.; Collivignarelli, C.; Plizzari, G.: Concrete with eaf steel slag as aggregate: a comprehensive technical and environmental characterisation. Compos. B Eng. 90, 195–202 (2016)

Suer, P.; Lindqvist, J.-E.; Arm, M.; Frogner-Kockum, P.: Reproducing ten years of road ageing—accelerated carbonation and leaching of eaf steel slag. Sci. Total Environ. 407(18), 5110–5118 (2009)

Pasetto, M.; Baldo, N.: Experimental evaluation of high performance base course and road base asphalt concrete with electric arc furnace steel slags. J. Hazard. Mater. 181(1–3), 938–948 (2010)

Miraoui, M.; Zentar, R.; Abriak, N.-E.: Road material basis in dredged sediment and basic oxygen furnace steel slag. Constr. Build. Mater. 30, 309–319 (2012)

Tripathi, B.; Misra, A.; Chaudhary, S.: Strength and abrasion characteristics of isf slag concrete. J. Mater. Civ. Eng. 25(11), 1611–1618 (2012)

Netinger, I.; Bjegović, D.; Vrhovac, G.: Utilisation of steel slag as an aggregate in concrete. Mater. Struct. 44(9), 1565–1575 (2011)

Mladenovič, A.; Mirtič, B.; Meden, A.; Serjun, V.Z.: Calcium aluminate rich secondary stainless steel slag as a supplementary cementitious material. Constr. Build. Mater. 116, 216–225 (2016)

Contrafatto, L.: Recycled etna volcanic ash for cement, mortar and concrete manufacturing. Constr. Build. Mater. 151, 704–713 (2017)

Kupwade-Patil, K.; Palkovic, S.D.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O.: Use of silica fume and natural volcanic ash as a replacement to portland cement: micro and pore structural investigation using nmr, xrd, ftir and x-ray microtomography. Constr. Build. Mater. 158, 574–590 (2018)

Mehta, A.; Siddique, R.: Strength, permeability and micro-structural characteristics of low-calcium fly ash based geopolymers. Constr. Build. Mater. 141, 325–334 (2017)

I. 1989: Indian Standard 43 Grade Ordinary Portland Cement Specification-Code of Practice (1989)

I. 44: Tentative Guidelines for Cement Concrete Mix Design for Pavements. New Delhi Indian Road Congress, pp. 1–16 (2008)

I. 10262-2009: Concrete Mix Proportioning—Guidelines (2009)

I. 516: Indian Standard Methods of Tests for Strength of Concrete (1959)

Wu, H.; Huang, B.; Shu, X.; Dong, Q.: Laboratory evaluation of abrasion resistance of portland cement pervious concrete. J. Mater. Civ. Eng. 23(5), 697–702 (2010)

Dong, Q.; Wu, H.; Huang, B.; Shu, X.; Wang, K.: Investigation into laboratory abrasion test methods for pervious concrete. J. Mater. Civ. Eng. 25(7), 886–892 (2012)

C. ASTM, 131: Standard Test Method for Resistance to Degradation of Small

U. EPA: Method 1311. Toxicity Characteristic Leaching Procedure (1992)

Han, F.; Zhang, Z.; Wang, D.; Yan, P.: Hydration heat evolution and kinetics of blended cement containing steel slag at different temperatures. Thermochim. Acta 605, 43–51 (2015)

Aggarwal, Y.; Siddique, R.: Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 54, 210–223 (2014)

Singh, M.; Siddique, R.: Strength properties and micro-structural properties of concrete containing coal bottom ash as partial replacement of fine aggregate. Constr. Build. Mater. 50, 246–256 (2014)

Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.: Geopolymer technology: the current state of the art. J. Mater. Sci. 42(9), 2917–2933 (2007)

Khale, D.; Chaudhary, R.: Mechanism of geopolymerization and factors influencing its development: a review. J. Mater. Sci. 42(3), 729–746 (2007)

Sharma, U.; Singh, L.; Zhan, B.; Poon, C.S.: Effect of particle size of nanosilica on microstructure of CSH and its impact on mechanical strength. Cem. Concr. Compos. 97, 312–321 (2019)

Shi, C.; Fernandez-Jimenez, A.: Stabilization/solidification of hazardous and radioactive wastes with alkali-activated cements. J. Hazard. Mater. 137(3), 1656–1663 (2006)

Kunther, W.; Ferreiro, S.; Skibsted, J.: Influence of the ca/si ratio on the compressive strength of cementitious calcium–silicate–hydrate binders. J. Mater. Chem. A 5(33), 17401–17412 (2017)

Patra, J.C.; Meher, P.K.; Chakraborty, G.: Nonlinear channel equalization for wireless communication systems using legendre neural networks. Sig. Process. 89(11), 2251–2262 (2009)

Funding

This research is not funded by any agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research Involving Human Participants and Animals

This research do not involve any human and animal participants.

Rights and permissions

About this article

Cite this article

Gupta, T., Sachdeva, S.N. Experimental Study and Modeling of Concrete Containing AOD Steel Slag for Pavements. Arab J Sci Eng 45, 8111–8127 (2020). https://doi.org/10.1007/s13369-020-04619-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04619-y