Abstract

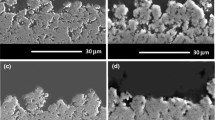

Zirconium tungsten nitride (Zr–W–N) coating has been deposited on 304 SS substrates by pulse DC magnetron sputtering. The average micro hardness and roughness of Zr–W–N coating were obtained as ~1,963 HV and ~13 nm respectively. The dry sliding and abrasive wear tests of coated samples were performed in open atmosphere at various loads (15–45 N) with constant speed (0.1 m/s) up to maximum life of a coating. The coefficient of friction (COF) and cumulative weight loss were measured as a function of distance travelled by the coating. The change (minimum to maximum) in COF of the coated samples at various loads was obtained as ~0.15–0.68 and ~0.20–0.27 for dry sliding wear and abrasive wear tests respectively. The cumulative weight loss of the coated samples at various loads was calculated as 1 × 10−6–6 × 10−6 g/m for dry sliding wear and 6 × 10−6–26 × 10−6 g/m for abrasive wear test. Finally, coatings were compared on COF and cumulative weight loss as a function of sliding distance with SS substrate at 15 N load with 0.1 m/s speed.

Similar content being viewed by others

References

Kimura A, and Suzuki T, J Vac Sci Technol A 18 (2000) 1038.

Tang Z Z, Ceram Int 38 (2012) 2997.

Gu B, Tu J P, Zheng X H, Yang Y Z, and Peng S M, Surf Coat Technol 202 (2008) 2189.

Yang B, Chen L, Chang K K, Wei P, Peng Y B, Yong D, and Yong L, Int J Refract Met Hard Mater 35 (2012) 235.

Klostermann H, Fietzke F, Modes T, and Zywitzki O, Rev Adv Mater Sci 15 (2007) 33.

Sun X, Reid J S, Kolawa E, and Nicolet M A, J Appl Phys 81 (1997) 656.

Soderberg J, Oden M, Aldareguia J M M, and Hultman L, J Appl Phys 97 (2005) 114327.

Kim S H, Kim J K, and Kim K H, Thin Solid Films 420–421 (2002) 360.

Chawla V, Jayaganthan R, and Chandra R, Surf Coat Technol 204 (2010) 1582.

Musil J, Daniel R, Zeman P, and Takai O, Thin Solid Films 478 (2005) 238.

Marques A P, and Cavaleiro A, Thin Solid Films 441 (2003) 150.

Wiedemann R, Weihnacht V, and Oettel H, Surf Coat Technol 116–119 (1999) 302.

Holleck H, J Vac Sci Technol A 4 (1986) 2661.

Zhao L R, Chen K, Yang Q, Rodgers J R, and Chiou S H, Surf Coat Technol 200 (2005) 1595.

Yamamot K, and Fox-Rabinovich, G, Hard films and sputtering targets for the deposition thereof, united states patent, US 7648781 B2, (2010).

Song D H, Yang G S, and Lee J K, Solid State Phenom 124–126 (2007) 1513.

Hsu C H, Lin C K, Huang K H, and Ou K L, Surf Coat Technol 31 (2013) 380.

Moser J H, Tian F, Haller O, Bergstrom D B, Petrov I, Greene J E, and Wiemer C, Thin Solid Films 253 (1994) 445.

Yang Q, and Zhao L R, Surf Coat Technol 200 (2005) 1709.

Regent F, and Musil J, Surf Coat Technol 142–144 (2001) 146.

Kim G-S, Kim Y-S, Kim S-M, Lee S-Y, Lee K-R, J Korean Phys Soc 54 (2009) 1569.

Purushotham K P, Ward L P, Brack N, Pigram P J, Evans P, Noorman H, and Manory R R, J Vac Sci Technol A 25 (2007) 110.

Ryan N E, J Less-Common Met 6 (1964) 21.

Schwarz K, Yee D S, Cuomo J J, and Harper J M E, Phys Rev B 32 (1985) 8.

Dubey P, Arya V, Srivastava S, Singh D, and Chandra R, Surf Coat Technol 236 (2013) 182.

Pei Y, Deng J, Wu Z, Li S, Xing Y, and Zhao J, Int J Refract Met Hard Mater 35 (2012) 213.

Zhang G P, Niu E W, Wang X Q, Lv G H, Zhou L, Pang H, Huang J, Chen W, and Yang S Z, Appl Surf Sci 258 (2012) 3674.

Silva P N, Dias J P, and Cavaleir A, Surf Coat Technol 200 (2005) 186.

Nossa A, and Cavaleir A, Surf Coat Technol 142–144 (2001) 984.

Hutchings I M, Tribology: friction and wear of engineering materials, Publisher by Edward Arnold, 1996, chaps 3, 5 and 6.

Acknowledgments

V. C. would like to acknowledge MHRD for financial support. This work has been supported by grant received under NPP scheme of CPRI, Bangalore, India via letter No. CPRI/CCAR/NPP/IITR/2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chauhan, V., Dubey, P., Verma, S. et al. Dry Sliding and Abrasive Wear Behavior of Nanostructure Zr–W–N Coating. Trans Indian Inst Met 68, 799–807 (2015). https://doi.org/10.1007/s12666-015-0513-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0513-0