Abstract

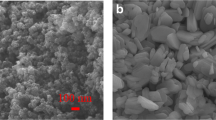

Nanostructured molybdenum carbide (Mo2C) was successfully prepared from molybdenum trioxide (MoO3) using methanothermal temperature-programmed reaction. Thermodynamic analysis indicated that in presence of methane, the formation of Mo2C from MoO3 occurs through the path of MoO3 → MoO2 → Mo2C. The carburized MoO3 was characterized using X-ray diffraction (XRD), CHNS/O analysis, Brunauer–Emmett–Teller (BET) analysis, and field-emission scanning electron microscopy (FESEM). At final carburization temperatures of 700 and 800°C and at methane contents ranging from 5vol% to 20vol%, Mo2C was the only solid product observed in the XRD patterns. The results indicated that the effect of methane content on the formation of the carbide phase is substantial compared with the effect of carburization time. Elemental analysis showed that at a final temperature of 700°C, the carbon content of carburized MoO3 is very close to the theoretical carbon mass percentage in Mo2C. At higher carburization temperatures, excess carbon was deposited onto the surface of Mo2C. High-surface-area Mo2C was obtained at extremely low heating rates; this high-surface-area material is a potential electrocatalyst.

Similar content being viewed by others

References

H.O. Pierson, Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing, and Applications, William Andrew Publishing/Noyes, Westwood, New Jersey, 1996, p. 8.

L. Elbaz, C.R. Kreller, N.J. Henson, and E.L. Brosha, Electrocatalysis of oxygen reduction with platinum supported on molybdenum carbide–carbon composite, J. Electroanal. Chem., 720-721(2014), p. 34.

L. Liao, S. Wang, J. Xiao, X. Bian, Y. Zhang, M.D. Scanlon, X. Hu, Y. Tang, B. Liu, and H.H. Girault, A nanoporous molybdenum carbide nanowire as an electrocatalyst for hydrogen evolution reaction, Energy Environ. Sci., 7(2014), No. 1, p. 387.

Y. Wang, B. Li, D. Cui, X. Xiang, and W. Li, Nano-molybdenum carbide/carbon nanotubes composite as bifunctional anode catalyst for high-performance Escherichia coli-based microbial fuel cell, Biosens. Bioelectron., 51(2014), p. 349.

M.L. Frauwallner, F. López-Linares, J. Lara-Romero, C.E. Scott, V. Ali, E. Hernández, and P. Pereira-Almao, Toluene hydrogenation at low temperature using a molybdenum carbide catalyst, Appl. Catal. A, 394(2011), No. 1–2, p. 62.

M.D. Porosoff, X. Yang, J.A. Boscoboinik, and J.G. Chen, Molybdenum carbide as alternative catalysts to precious metals for highly selective reduction of CO2 to CO, Angew. Chem., 126(2014), No. 26, p. 6823.

W. Zheng, T.P. Cotter, P. Kaghazchi, T. Jacob, B. Frank, K. Schlichte, W. Zhang, D.S. Su, F. Schüth, and R. Schlögl, Experimental and theoretical investigation of molybdenum carbide and nitride as catalysts for ammonia decomposition, J. Am. Chem. Soc., 135(2013), No. 9, p. 3458.

D.V.N. Vo and A.A. Adesina, Fischer–Tropsch synthesis over alumina-supported molybdenum carbide catalyst, Appl. Catal. A, 399(2011), No. 1–2, p. 221.

J.A. Schaidle, N.M. Schweitzer, O.T. Ajenifujah, and L.T. Thompson, On the preparation of molybdenum carbide- supported metal catalysts, J. Catal., 289(2012), p. 210.

Q. Wu, J.M. Christensen, G.L. Chiarello, L.D.L. Duchstein, J.B. Wagner, B. Temel, J.D. Grunwaldt, and A.D. Jensen, Supported molybdenum carbide for higher alcohol synthesis from syngas, Catal. Today, 215(2013), p. 162.

E.F. Mai, M.A. Machado, T.E. Davies, J.A. Lopez-Sanchez, and V. Teixeira da Silva, Molybdenum carbide nanoparticles within carbon nanotubes as superior catalysts for valerolactone production via levulinic acid hydrogenation, Green Chem., 16(2014), No. 9, p. 4092.

T. Hirose, Y. Ozawa, and M. Nagai, Preparation of a nickel molybdenum carbide catalyst and its activity in the dry reforming of methane, Chin. J. Catal., 32(2011), No. 5, p. 771.

Y. Ma, G. Guan, C. Shi, A. Zhu, X. Hao, Z. Wang, K. Kusakabe, and A. Abudula, Low-temperature steam reforming of methanol to produce hydrogen over various metal-doped molybdenum carbide catalysts, Int. J. Hydrogen Energy, 39(2014), No. 1, p. 258.

C. Liu, M. Lin, D. Jiang, K. Fang, and Y. Sun, Preparation of promoted molybdenum carbides nanowire for CO hydrogenation, Catal. Lett., 144(2014), No. 4, p. 567.

P.A. Aegerter, W.W.C. Quigley, G.J. Simpson, D.D. Ziegler, J.W. Logan, K.R. McCrea, S. Glazier, and M.E. Bussell, Thiophene hydrodesulfurization over alumina-supported molybdenum carbide and nitride catalysts: adsorption sites, catalytic activities, and nature of the active surface, J. Catal., 164(1996), No. 1, p. 109.

D.J. Sajkowski and S.T. Oyama, Catalytic hydrotreating by molybdenum carbide and nitride: unsupported MO2N and MO2CAl2O3, Appl. Catal. A, 134(1996), No. 2, p. 339.

S. Ramanathan and S.T. Oyama, New catalysts for hydroprocessing: transition metal carbides and nitrides, J. Phys. Chem., 99(1995), No. 44, p. 16365.

S. Boullosa-Eiras, R. Lødeng, H. Bergem, M. Stöcker, L. Hannevold, and E.A. Blekkan, Catalytic hydrodeoxygenation (HDO) of phenol over supported molybdenum carbide, nitride, phosphide and oxide catalysts, Catal. Today, 223(2014), p. 44.

J. Han, J. Duan, P. Chen, H. Lou, X. Zheng, and H. Hong, Nanostructured molybdenum carbides supported on carbon nanotubes as efficient catalysts for one-step hydrodeoxygenation and isomerization of vegetable oils, Green Chem., 13(2011), No. 9, p. 2561.

J. Patt, D.J. Moon, C. Phillips, and L. Thompson, Molybdenum carbide catalysts for water–gas shift, Catal. Lett., 65(2000), No. 4, p. 193.

N.M. Schweitzer, J.A. Schaidle, O.K. Ezekoye, X. Pan, S. Linic, and L.T. Thompson, High activity carbide supported catalysts for water gas shift, J. Am. Chem. Soc., 133(2011), No. 8, p. 2378.

S.T. Oyama, The Chemistry of the Transition Metal Carbides and Nitrides, Edited by S.T. Oyama, Blackie Academic & Professional, Bishopbriggs, Glasgow, 1996, p. 17.

R. Alizadeh, E. Jamshidi, and H. Ale-Ebrahim, Kinetic study of nickel oxide reduction by methane, Chem. Eng. Technol., 30(2007), No. 8, p. 1123.

B. Khoshandam, E. Jamshidi, and R.V. Kumar, Reduction of cobalt oxide with methane, Metall. Mater. Trans. B, 35(2004), No. 5, p. 825.

H. Ale Ebrahim and E. Jamshidi, Kinetic study of zinc oxide reduction by methane, Chem. Eng. Res. Des., 79(2001), No. 1, p. 62.

B. Khoshandam, R.V. Kumar, and E. Jamshidi, Producing chromium carbide using reduction of chromium oxide with methane, AIChE J., 52(2006), No. 3, p. 1094.

R. Alizadeh and O. Ostrovski, Kinetic study of synthesis of titanium carbide by methanothermal reduction of titanium dioxide, Iran. J. Mater. Sci. Eng., 8(2011), No. 1, p. 1.

G. Zhang and O. Ostrovski, Reduction of titania by methane-hydrogen-argon gas mixture, Metall. Mater. Trans. B, 31(2000), No. 1, p. 129.

G.S. Ranhotra, G.W. Haddix, A.T. Bell, and J.A. Reimer, Catalysis over molybdenum carbides and nitrides: I. Catalyst characterization, J. Catal., 108(1987), No. 1, p. 24.

A. Hanif, T. Xiao, A.P.E. York, J. Sloan, and M.L.H. Green, Study on the structure and formation mechanism of molybdenum carbides, Chem. Mater., 14(2002), No. 3, p. 1009.

T. Xiao, A.P.E. York, K.S. Coleman, J.B. Claridge, J. Sloan, J. Charnock, and M.L.H. Green, Effect of carburising agent on the structure of molybdenum carbides, J. Mater. Chem., 11(2001), No. 12, p. 3094.

P. Roohi, R. Alizadeh, and E. Fatehifar, Thermodynamic study of transformation of methane to synthesis gas over metal oxides, Int. J. Thermophys., 36(2015), No. 1, p. 88.

M.W. Chase, C.A. Davies, J.R. Downey, D.J. Frurip, R.A. McDonald, and A.N. Syverud, JANAF thermochemical tables, 3rd ed. J. Phys. Chem. Ref. Data, 14(1985), Suppl. 1, p. 1.

J.S. Lee, L. Volpe, F.H. Ribeiro, and M. Boudart, Molybdenum carbide catalysts: II. Topotactic synthesis of unsupported powders, J. Catal., 112(1988), No. 1, p. 44.

R. Alizadeh, E. Jamshidi, and G. Zhang, Transformation of methane to synthesis gas over metal oxides without using catalyst, J. Nat. Gas Chem., 18(2009), No. 2, p. 124.

S.T. Oyama, Preparation and catalytic properties of transition metal carbides and nitrides, Catal. Today, 15(1992), No. 2, p. 179.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roohi, P., Alizadeh, R. & Fatehifar, E. Thermodynamic study and methanothermal temperature-programmed reaction synthesis of molybdenum carbide. Int J Miner Metall Mater 23, 339–347 (2016). https://doi.org/10.1007/s12613-016-1243-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1243-y