Abstract

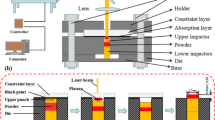

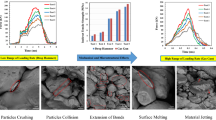

High-velocity compaction (HVC) provides an effective means in the field of powder metallurgy (P/M) to reduce the porosity as well as to ameliorate the mechanical properties of products. In this study, the green density of an aluminum alloy is found to be 2.783 g·cm−3. The ejection force for the aluminum alloy is in the range of 23 to 80 kN and the spring back is found to be less than 0.40%. The hardness of the green body is in the range of HRB 30 to 70. The bending strength of the green body is in the range of 6 to 26 MPa, which are higher than that of other aluminum alloys prepared by the traditional compaction method.

Similar content being viewed by others

References

A. Gökçe, F. Findik, and A.O. Kurt, Microstructural exami nation and properties of premixed Al-Cu-Mg powder metallurgy alloy, Mater. Charact., 62(2011), No.7, p.730.

A.D.P. LaDelpha, M.P. Mosher, W.F. Caley, G.J. Kipouros, and D.P. Bishop, On the simulation of wrought AA4032 via P/M processing, Mater. Sci. Eng. A, 479(2008), No.1–2, p.1.

V.K. Vasudevan and H.L. Fraser, The microstructures of rapidly solidified and heat-treated Al-8Fe-2Mo-Si alloys, Mater. Sci. Eng., 98(1988), p.131.

W.G.E. Mosher, G.J. Kippouros, W.F. Caley, I.W. Donaldson, and D.P. Bishop, On hot deformation of aluminium-silicon powder metallurgy alloys, Powder Metall., 54(2011), No.3, p.366.

I.A. MacAskill, D.W. Heard, and D.P. Bishop, Effects of silicon on the metallurgy and sintering response of Al-Ni-Mg PM alloys, Mater. Sci. Eng. A, 452–453(2007), p.688.

A.D.P. LaDelpha, H. Neubing, and D.P. Bishop, Metallurgical assessment of an emerging Al-Zn-Mg-Cu P/M alloy, Mater. Sci. Eng. A, 520(2009), No.1–2, p.105.

R.E.D. Mann, R.L Hexemer, I.W. Donaldson, and D.P. Bishop, Hot deformation of an Al-Cu-Mg powder metallurgy alloy, Mater. Sci. Eng. A, 528(2011), No.16–17, p.5476.

K.S. Dunnett, R.M. Mueller, and D.P. Bishop, Development of Al-Ni-Mg-(Cu) aluminum P/M alloys, J. Mater. Process. Technol., 198(2008), No.1–3, p.31.

T. Ericsson and P. Luukkonen, Residual stresses in green bodies of steel powder after conventional and high speed compaction, Mater. Sci. Forum, 404–407(2002), p.77.

J.Z. Wang, X.H. Qu, H.Q. Yin, M.J. Yi, and X.J. Yuan, High velocity compaction of ferrous powder, Powder Technol., 192(2009), p.131.

Z.Q. Yan, F. Chen, and Y.X. Cai, High-velocity compaction of titanium powder and process characterization, Powder Technol., 208(2011), p.596.

D. Vojtěch, A. Michalcová, J. Pilch, P. Šittner, J. Šerák, and P. Novák, Structural characteristics and thermal stability of Al-5.7Cr-2.5Fe-1.3Ti alloy produced by powder metallurgy, J. Alloys Compd., 475(2009), No.1–2, p.151.

J.Z. Wang, H.Q. Yin, X.H. Qu, and J.L. Johnson, Effect of multiple impacts on high velocity pressed iron powder, Powder Technol., 195(2009), No.3, p.184.

I. Arribas, J.M. Martín, and F. Castro, The initial stage of liquid phase sintering for an Al-14Si-2.5Cu-0.5Mg (wt%) P/M alloy, Mater. Sci. Eng. A, 527(2010), No.16–17, p.3949.

J.Z. Wang, X.H. Qu, H.Q. Yin, S.Y. Zhou, and M.J. Yi, High velocity compaction of electrolytic copper powder, Chin. J. Nonferrous Met., 18(2008), No.8, p.1498.

F. Dore, L. Lazzarotto, and S. Bourdin, High velocity compaction: overview of materials, applications and potential, Mater. Sci. Forum, 534–536(2007), p.293.

P. Skoglund, High density PM parts by high velocity compaction, Powder Metall., 44(2001), No.3, p.199.

D.W. Heard, I.W. Donaldson, and D.P. Bishop, Metallurgical assessment of a hypereutectic aluminum-silicon P/M alloy, J. Mater. Process. Technol., 209(2009), No.18–19, p.5902.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the Major State Basic Research and Development Program of China (No.2006CB605207) and the MOE Program for Cheung Kong Scholars and Innovative Research Teams in Universities of China (No.I2P407).

Rights and permissions

About this article

Cite this article

Yuan, Xj., Yin, Hq., Din, Ru. et al. Study on the impact force and green properties of high-velocity compacted aluminum alloy powder. Int J Miner Metall Mater 19, 1107–1113 (2012). https://doi.org/10.1007/s12613-012-0678-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0678-z