Abstract

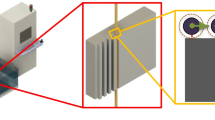

This paper presents an imprinting process, which can impart hydrophobicity to aluminum alloy surfaces, and a method for analyzing the wetting states of solid surfaces with multi-scale structures. Electrical discharge textured (EDT) surface and groove pattern molds were produced by electrical discharge machining (EDM) and wire electrical discharge machining (WEDM), respectively. The aluminum surfaces having hierarchical patterns were produced by imprinting processes using both EDT surface and groove pattern molds. The groove patterns with various pitches from 400 to 1,000 µm were applied to the mold designs, so that the effects on static water contact angle (WCA) could be analyzed. Results showed that the hydrophobic aluminum surface with WCA of 117.6° can be achieved through the facile imprinting process. In addition, a wetting state analysis method using air layer images was proposed. Using this method, it was demonstrated that the surface wetting state can be accurately analyzed by combining the air layer images and the theoretical models such as the Cassie–Baxter, and Wenzel models.

Similar content being viewed by others

References

Moon, I. Y. (2019). Surface wettability controls based on hot imprinting process. Doctoral dissertation: Pusan National University, Busan.

Martin, S., Brown, P. S., & Bhushan, B. (2017). Fabrication techniques for bioinspired, mechanically-durable, superliquiphobic surfaces for water, oil, and surfactant repellency. Advances in colloid and interface science, 241, 1–23.

Yan, Y. Y., Gao, N., & Barthlott, W. (2011). Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces. Advances in colloid and interface science, 169(2), 80–105.

Simpson, J. T., Hunter, S. R., & Aytug, T. (2015). Superhydrophobic materials and coatings: a review. Reports on Progress in Physics, 78(8), 086501.

Genzer, J., & Efimenko, K. (2006). Recent developments in superhydrophobic surfaces and their relevance to marine fouling: a review. Biofouling, 22(5), 339–360.

Zhan, Y. L., Ruan, M., Li, W., Li, H., Hu, L. Y., Ma, F. M., & Feng, W. (2017). Fabrication of anisotropic PTFE superhydrophobic surfaces using laser microprocessing and their self-cleaning and anti-icing behavior. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 535, 8–15.

Toosi, S. F., Moradi, S., Kamal, S., & Hatzikiriakos, S. G. (2015). Superhydrophobic laser ablated PTFE substrates. Applied Surface Science, 349, 715–723.

Chun, D. M., Davaasuren, G., Ngo, C. V., Kim, C. S., Lee, G. Y., & Ahn, S. H. (2014). Fabrication of transparent superhydrophobic surface on thermoplastic polymer using laser beam machining and compression molding for mass production. CIRP Annals, 63(1), 525–528.

Chun, D. M., Ngo, C. V., and Lee, K. M. (2016). Fast fabrication of superhydrophobic metallic surface using nanosecond laser texturing and low-temperature annealing. CIRP Annals, 65(1), 519–522.

Ngo, C. V., & Chun, D. M. (2017). Fast wettability transition from hydrophilic to superhydrophobic laser-textured stainless steel surfaces under low-temperature annealing. Applied Surface Science, 409, 232–240.

Liao, R., Zuo, Z., Guo, C., Yuan, Y., & Zhuang, A. (2014). Fabrication of superhydrophobic surface on aluminum by continuous chemical etching and its anti-icing property. Applied Surface Science, 317, 701–709.

Qian, B., & Shen, Z. (2005). Fabrication of superhydrophobic surfaces by dislocation-selective chemical etching on aluminum, copper, and zinc substrates. Langmuir, 21(20), 9007–9009.

Bae, W. G., Kim, D., Song, K. Y., Jeong, H. E., & Chu, C. N. (2015). Engineering stainless steel surface via wire electrical discharge machining for controlling the wettability. Surface and Coatings Technology, 275, 316–323.

Bae, W. G., Song, K. Y., Rahmawan, Y., Chu, C. N., Kim, D., Chung, D. K., & Suh, K. Y. (2012). One-step process for superhydrophobic metallic surfaces by wire electrical discharge machining. ACS applied materials & interfaces, 4(7), 3685–3691.

Weisensee, P. B., Torrealba, E. J., Raleigh, M., Jacobi, A. M., & King, W. P. (2014). Hydrophobic and oleophobic re-entrant steel microstructures fabricated using micro electrical discharge machining. Journal of Micromechanics and Microengineering, 24(9), 095020.

Cho, Y. H., Seo, Y. S., Moon, I. Y., Kim, B. H., & Park, K. (2013). Facile fabrication of superhydrophobic poly (methyl methacrylate) substrates using ultrasonic imprinting. Journal of Micromechanics and Microengineering, 23(5), 055019.

Schmid, G., Levering, M., & Sawitowski, T. (2007). Nanostructured surfaces of metals and polymers by imprinting with nanoporous alumina. Zeitschrift für anorganische und allgemeine Chemie, 633(13–14), 2147–2153.

Lin, Y. C., Hsu, S. H., & Chung, Y. C. (2013). Thermal imprint techniques for preparation of superhydrophobic polymer coatings. Surface and Coatings Technology, 231, 501–506.

Jucius, D., Grigaliūnas, V., Mikolajūnas, M., Guobienė, A., Kopustinskas, V., Gudonytė, A., & Narmontas, P. (2011). Hot embossing of PTFE: Towards superhydrophobic surfaces. Applied Surface Science, 257(6), 2353–2360.

Moon, I. Y., Kim, B. H., Lee, H. W., Oh, Y. S., Kim, J. H., & Kang, S. H. (2020). Superhydrophobic Polymer Surface with Hierarchical Patterns Fabricated in Hot Imprinting Process. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 493–503.

Moon, I. Y., Lee, H. W., Oh, Y. S., Kim, S. J., & Kang, S. H. (2019). Characterization of microfibril development on PTFE surface during hot imprinting process and its application for oil–water separation. The International Journal of Advanced Manufacturing Technology, 102(5), 1871–1883.

Moon, I. Y., Lee, H. W., Oh, Y. S., Kim, S. J., Kim, J. H., & Kang, S. H. (2019). Development of a roll-to-roll hot imprinting process for superhydrophobic polytetrafluoroethylene surfaces. Journal of Micromechanics and Microengineering, 29(11), 115003.

Long, J., Zhong, M., Zhang, H., & Fan, P. (2015). Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air. Journal of colloid and interface science, 441, 1–9.

Wenzel, R. N. (1936). Resistance of solid surfaces to wetting by water. Industrial & Engineering Chemistry, 28(8), 988–994.

Cassie, A. B. D., & Baxter, S. (1944). Wettability of porous surfaces. Transactions of the Faraday society, 40, 546–551.

Rahmawan, Y., Moon, M. W., Kim, K. S., Lee, K. R., & Suh, K. Y. (2009). Wrinkled, dual-scale structures of diamond-like carbon (DLC) for superhydrophobicity. Langmuir, 26(1), 484–491.

Shi, F., Niu, J., Liu, J., Liu, F., Wang, Z., Feng, X. Q., & Zhang, X. (2007). Towards understanding why a superhydrophobic coating is needed by water striders. Advanced Materials, 19(17), 2257–2261.

Poetes, R., Holtzmann, K., Franze, K., & Steiner, U. (2010). Metastable underwater superhydrophobicity. Physical review letters, 105(16), 166104.

Vakarelski, I. U., Chan, D. Y., Marston, J. O., & Thoroddsen, S. T. (2013). Dynamic air layer on textured superhydrophobic surfaces. Langmuir, 29(35), 11074–11081.

Sheng, X., & Zhang, J. (2011). Air layer on superhydrophobic surface underwater. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 377(1–3), 374–378.

Takeda, S., & Fukawa, M. (2005). Role of surface OH groups in surface chemical properties of metal oxide films. Materials Science and Engineering: B, 119(3), 265–267.

Acknowledgements

This research was financially supported by the Ministry of Trade, Industry, and Energy (MOTIE), Korea, under the “Digital manufacturing platform (DigiMaP)” (reference number N0002598) supervised by the Korea Institute for Advancement of Technology (KIAT). This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (2019R1A2C4070160). Author Dr. Seong-Hoon Kang thanks for support from the Basic Research Program of the Korea Institute of Materials Science. The authors have no conflict of interests to declare.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moon, I.Y., Kang, SH. & Yoon, J. Hydrophobic Aluminum Alloy Surfaces Fabricated by Imprinting Process and Their Wetting State Evaluation Using Air Layer Images. Int. J. Precis. Eng. Manuf. 22, 147–159 (2021). https://doi.org/10.1007/s12541-020-00441-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00441-6