Abstract

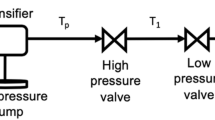

Fluid foods are a rapidly growing segment serving the needs of consumers’ healthy life style. Though high-pressure pasteurized beverages have been recently commercialized, the batch nature of the technology has been a hurdle for wider adaptation of the technology for high-throughput commodity-oriented beverage products. Further development of continuous flow through high-pressure processing methods is desired. High-pressure homogenization (HPH) consists of forcing a pressurized fluid to flow through a minute gap, which not only homogenizes the fluid but also increases the fluid’s temperature. HPH offers the possibility of combining homogenization and preservation into a single unit operation. By manipulating initial temperature and applied pressure, HPH treatment can be used to pasteurize or sterilize the product. This work critically examines the efforts in understanding fundamental process engineering aspects of HPH, including pressure-thermal process characterization, valve design (gap size and pressure relation), flow pattern, temperature history, and residence time distribution. This review will also highlight the HPH impact on food quality and bioactive compound retention. Quality aspects examined include particle size distribution and microbial and enzyme inactivation. The insight gained by this review will assist readers to gain a better appreciation of the HPH process design and system scale-up.

Similar content being viewed by others

Abbreviations

- AMG:

-

Amyloglucosidase

- CFD:

-

Computational fluid dynamics

- GO:

-

Glucose oxidase

- HPH:

-

High-pressure homogenization

- HPP:

-

High pressure processing

- NP:

-

Neutral protease

- PEF:

-

Pulse electric field

- PEL:

-

Pectate lyase

- PME:

-

Pectin methyl esterase

- PPO:

-

Polyphenoloxidase

- RTD:

-

Residence time distribution

- SH:

-

Standard homogenization

- TR:

-

Trypsin

- UHT:

-

Ultra-high-temperature

- β-Gal:

-

β-Galactosidase

References

Auty MA, Gee VL, Ciron CI (2011) Making low-fat yoghurts cremier through dynamic pressure processing. New Food issue 6. www.newfoodmagazine.com. Accessed March 10 2015

Balasubramaniam VM, Martínez-Monteagudo SI, Gupta R (2015) Principles and application of high pressure based technologies in the food industry. Annu Rev Food Sci Technol 6:435–462

Balasubramaniam VM, Barbosa-Canovas GV, Lelieveld H (2016) High pressure processing of food-principles. Technology and Application, Springer-Verlag New York

Baldyga J, Bourne JR (1999) Turbulent mixing and chemical reactions. John Wiley & Sons Ltd, West Sussex

Baldyga J, Pohorecki R (1995) Turbulent micromixing in chemical reactors—a review. Chem Eng J Biochem Eng J 58:183–195

Becker PJ, Puel F, Dubbelboer A, Janssen J, Sheibat-Othman N (2014) Coupled population balance–CFD simulation of droplet breakup in a high pressure homogenizer. Comput Chem Eng 68:140–150

Bevilacqua A, Cibelli F, Corbo MR, Sinigaglia M (2007) Effects of high-pressure homogenization on the survival of Alicyclobacillus acidoterrestris in a laboratory medium. Lett Appl Microbiol 45:382–386

Briñez WJ, Roig-Sagués AX, Herrero M, Lopez BG (2006a) Inactivation by ultrahigh-pressure homogenization of Escherichia coli strains inoculated into orange juice. J Food Protec 69:984–989

Briñez WJ, Roig-Sagues AX, Herrero M, Lopez BG (2006b) Inactivation of Listeria innocua in milk and orange juice by ultrahigh-pressure homogenization. J Food Protec 69:86–92

Briñez WJ, Roig-Sagués AX, Herrero MMH, López BG (2007) Inactivation of Staphylococcus spp. strains in whole milk and orange juice using ultra high pressure homogenisation at inlet temperatures of 6 and 20 °C. Food Control 18:1282–1288

Burgaud I, Dickinson E, Nelson PV (1990) An improved high-pressure homogenizer for making fine emulsions on a small scale. Int J Food Sci Technol 25:39–46

Calligaris S, Foschia M, Bartolomeoli I, Maifreni M, Manzocco L (2012) Study on the applicability of high-pressure homogenization for the production of banana juices. LWT - Food Sci Technol 45:117–121

Camp TR, Shin RW (1995) Turbulence intensity and length scale measurements in multistage compressors. J Turbomach 117:38–46

Carlton JS (2012) Cavitation. In: Carlton JS (ed) Marine propellers and propulsion, 1st edn. Butterworth-Heinemann, Oxford

Carreño JM, Gurrea MC, Sampedro F, Carbonell JV (2011) Effect of high hydrostatic pressure and high-pressure homogenisation on Lactobacillus plantarum inactivation kinetics and quality parameters of mandarin juice. Eur Food Res Technol 232:265–274

Casoli P, Vacca A, Berta GL (2010) A numerical procedure for predicting the performance of high pressure homogenizing valves. Simul Model Pract Th 18:125–138

Colle I, Van Buggenhout S, Van Loey A, Hendrickx M (2010) High pressure homogenization (HPH) followed by thermal processing of tomato pulp: influence on microstructure and lycopene in vitro bioaccessibility. Food Res Int 43:2193–2200

Cook EJ, Lagase AP (1985) Apparatus for forming emulsions. United States of America Patent No 4, 533, 254 August 6

Davies JT (1985) Drop sizes of emulsions related to turbulent energy dissipation rates. Chem Eng Sci 40:839–842

Desrumaux A, Marcand J (2002) Formation of sunflower oil emulsions stabilized by whey proteins with high-pressure homogenization (up to 350 MPa): effect of pressure on emulsion characteristics. Int J Food Sci Tech 37:263–269

Diels AM, Wuytack EY, Michiels CW (2003) Modelling inactivation of Staphylococcus aureus and Yersinia enterocolitica by high-pressure homogenisation at different temperatures. Int J Food Microbiol 87:55–62

Diels AM, Callewaert L, Wuytack EY, Masschalck B, Michiels CW (2004) Moderate temperatures affect Escherichia coli inactivation by high-pressure homogenization only through fluid viscosity. Biotechnol Prog 20:1512–1517

Diels AM, De Taeye J, Michiels CW (2005a) Sensitisation of Escherichia coli to antibacterial peptides and enzymes by high-pressure homogenisation. Int J Food Microbiol 105:165–175

Diels AM, Callewaert L, Wuytack EY, Masschalck B, Michiels CW (2005b) Inactivation of Escherichia coli by high-pressure homogenisation is influenced by fluid viscosity but not by water activity and product composition. Int J Food Microbiol 101:281–291

Dong P, Georget ES, Kemal A, Heinz V, Mathys A (2015) Ultra high pressure homogenization (UHPH) inactivation of Bacillus amyloliquefaciens spores in phosphate buffered saline (PBS) and milk. Front Microbiol 6:1–11

Donsì F, Ferrari G, Maresca P (2009a) High-pressure homogenization for food sanitization. In: Barbosa-Cánovas GV, Mortimer A, Lineback D, Spiess W, Buckle K, Colonna P (eds) Global issues in food science and technology, 1st edn. Academic Press, San Diego

Donsì F, Ferrari G, Lenza E, Maresca P (2009b) Main factors regulating microbial inactivation by high-pressure homogenization: operating parameters and scale of operation. Chem Eng Sci 64:520–532

Donsì F, Sessa M, Ferrari G (2011) Effect of emulsifier type and disruption chamber geometry on the fabrication of food nanoemulsions by high pressure homogenization. Ind Eng Chem Res 51:7606–7618

Dubbelboer A, Janssen J, Hoogland H, Mudaliar A, Maindarkar S, Zondervan E, Meuldijk J (2014) Population balances combined with computational fluid dynamics: a modeling approach for dispersive mixing in a high pressure homogenizer. Chem Eng Sci 117:376–388

Dumay E, Chevalier-Lucia D, Picart-Palmade L, Benzaria A, Gracia-Julia A, Blayo C (2013) Technological aspects and potential applications of (ultra) high-pressure homogenisation. Trends Food Sci Tech 31:13–26

Eggers R (2012) Basic engineering aspects. In: Eggers R (ed) Industrial high pressure applications, processes, equipment and safety, 1st edn. Weinheim, Wiley-VCH Verlag GmbH & Co

Endo H (1994) Thermodynamic consideration of the cavitation mechanism in homogeneous liquids. J Acoust Soc Am 95:2409–2415

Espejo GGA, Hernández-Herrero MM, Juan B, Trujillo AJ (2014) Inactivation of Bacillus spores inoculated in milk by ultra high pressure homogenization. Food Microbiol 44:204–210

Finke JH, Niemann S, Richter C, Gothsch T, Kwade A, Büttgenbach S, Müller-Goymann CC (2014) Multiple orifices in customized microsystem high-pressure emulsification: the impact of design and counter pressure on homogenization efficiency. Chem Eng J 248:107–121

Floury J, Desrumaux A, Lardieres J (2000) Effect of high-pressure homogenization on droplet size distributions and rheological properties of model oil-in-water emulsions. Innov Food Sci Emerg Tech 1:127–134

Floury J, Bellettre J, Legrand J, Desrumaux A (2004) Analysis of a new type of high pressure homogeniser. A study of the flow pattern. Chem Eng Sci 59:843–853

Førde ØO (2012) Analysis of the turbulent energy dissipation. Master Thesis, Norwegian University of Science and Technology

Georget E, Miller B, Aganovic K, Callanan M, Heinz V, Mathys A (2014a) Bacterial spore inactivation by ultra-high pressure homogenization. Innov Food Sci Emerg 26:116–123

Georget E, Miller B, Callanan M, Heinz V, Mathys A (2014b) (Ultra) high pressure homogenization for continuous high pressure sterilization of pumpable foods—a review. Frontiers Nutr 1:1–5

Gogate PR, Shirgaonkar IZ, Sivakumar M, Senthilkumar P, Vichare NP, Pandit AB (2001) Cavitation reactors: efficiency assessment using a model reaction. AICHE J 47:2526–2538

Grandi S, Gandini M (2006) Homogenization valve. United States of America Patent No. 7, 144, 149 B2. December 5

Håkansson A, Hounslow MJ (2013) Simultaneous determination of fragmentation and coalescence rates during pilot-scale high-pressure homogenization. J Food Eng 116:7–13

Håkansson A, Trägårdh C, Bergenståhl B (2009) Studying the effects of adsorption, recoalescence and fragmentation in a high pressure homogenizer using a dynamic simulation model. Food Hydrocoll 23:1177–1183

Håkansson A, Fuchs L, Innings F, Revstedt J, Trägårdh C (2010) Visual observations and acoustic measurements of cavitation in an experimental model of a high-pressure homogenizer. J Food Eng 100:504–513

Håkansson A, Fuchs L, Innings F, Revstedt J (2012) Experimental validation of k–ε RANS-CFD on a high-pressure homogenizer valve. Chem Eng Sci 71:264–273

Hayes MG, Fox PF, Kelly AL (2005) Potential applications of high pressure homogenisation in processing of liquid milk. J Dairy Res 72:25–33

Hinze JO (1955) Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes. AICHE J 1:289–295

Huppertz T (2011) Homogenization of milk. High-pressure homogenizers. In: Fuquay JW (ed) Encyclopedia of dairy, 2nd edn . Academic Press, San Diego

Innings F, Trägårdh C (2005) Visualization of the drop deformation and break-up process in high pressure homogenizer. Chem Eng Technol 28:882–891

Innings F, Trägårdh C (2007) Analysis of the flow field in a high-pressure homogenizer. Exp Thermal Fluid Sci 32:345–354

Innings F, Hultman E, Forsberg F, Prakash B (2011) Understanding and analysis of wear in homogenizers for processing liquid food. Wear 271:2588–2598

Jafari SM, Assadpoor E, He Y, Bhandari B (2008) Re-coalescence of emulsion droplets during high-energy emulsification. Food Hydroc 22:1191–1202

Jairus RD, Graves RH, Carlson VR (1995) Aseptic processing and packaging of food and beverages: a food industry perspective. CRC Press, Boca Raton, FL

Júnior CLBR, Tribst AAL, Cristianini M (2014) Proteolytic and milk-clotting activities of calf rennet processed by high pressure homogenization and the influence on the rheological behavior of the milk coagulation process. Innov Food Sci Emerg 21:44–49

Kawaguchi T (1971) Entrance loss for turbulent flow without swirl between parallel discs. Bulletin of JSME 14:355–363

Kelemen K, Schuch AC, Schuchmann HP (2014) Influence of flow conditions in high-pressure orifices on droplet disruption of oil-in-water emulsions. Chem Eng Technol 37:1227–1234

Kelly WJ, Muske KR (2004) Optimal operation of high-pressure homogenization for intracellular product recovery. Bioprocess Biosyst Eng 27:25–37

Kinney RR, Pandolfe WD, Ferguson RD (1999) Homogenization valve. United States of America Patent No. 5, 899, 564. May 4

Kleinig AR, Middelberg APJ (1997) Numerical and experimental study of a homogenizer impinging jet. AICHE J 43:1100–1107

Kumar PS, Pandit AB (1999) Modeling hydrodynamic cavitation. Chem Eng Technol 22:1017–1027

Kumar S, Thippareddi H, Subbiah J, Zivanovic S, Davidson PM, Harte F (2009) Inactivation of Escherichia coli K-12 in apple juice using combination of high-pressure homogenization and chitosan. J Food Sci 74:M8–M14

Lacroix N, Fliss I, Makhlouf J (2005) Inactivation of pectin methylesterase and stabilization of opalescence in orange juice by dynamic high pressure. Food Res Int 38:569–576

Lanciotti R, Sinigaglia M, Angelini P, Guerzoni ME (1994) Effects of homogenization pressure on the survival and growth of some food spoilage and pathogenic micro-organisms. Lett Appl Microbiol 18:319–322

Lee LL, Niknafs N, Hancocks RD, Norton IT (2013) Emulsification: mechanistic understanding. Trends Food Sci Technol 31:72–78

Liu W, Liu J, Liu C, Zhong Y, Liu W, Wan J (2009a) Activation and conformational changes of mushroom polyphenoloxidase by high pressure microfluidization treatment. Innov Food Sci Emerg 10:142–147

Liu W, Liu J, Xie M, Liu C, Liu W, Wan J (2009b) Characterization and high-pressure microfluidization-induced activation of polyphenoloxidase from Chinese pear (Pyrus pyrifolia Nakai). J Agr Food Chem 57:5376–5380

Liu W, Zhang ZQ, Liu CM, Xie MY, Tu ZC, Liu JH, Liang RH (2010) The effect of dynamic high-pressure microfluidization on the activity, stability and conformation of trypsin. Food Chem 123:616–621

Lobo L, Svereika A, Nair M (2002) Coalescence during emulsification: 1. Method development. J Coll Inter Sci 253:409–418

Loo CC, Slatter WL, Powell RW (1950) A study of the cavitation effect in the homogenization of dairy products. J Dairy Sci 33:692–702

López-Pedemonte T, Brinẽz WJ, Roig-Sagués AX, Guamis B (2006) Fate of Staphylococcus aureus in cheese treated by ultrahigh pressure homogenization and high hydrostatic pressure. J Dairy Sci 89:4536–4544

Marco-Molés R, Hernando I, Llorca E, Pérez-Munuera I (2012) Influence of high pressure homogenization (HPH) on the structural stability of an egg/dairy emulsion. J Food Eng 109:652–658

Maresca P, Donsì F, Ferrari G (2011) Application of a multi-pass high-pressure homogenization treatment for the pasteurization of fruit juices. J Food Eng 104:364–372

Martínez-Monteagudo SI, Saldaña MD (2014) Chemical reactions in food systems at high hydrostatic pressure. Food Eng Rev 6:105–127

Martínez-Monteagudo SI, Kamat S, Patel N, Konuklar G, Rangavajla N, Balasubramaniam VM (2017) Improvements in emulsion stability of dairy beverages treated by high pressure homogenization: a pilot-scale feasibility study. Journal Food Eng 193:42–52

McClements DJ (2004) Food emulsions: principles, practices, and techniques. CRC press, Boca Raton, Florida

Michaels AS, Hauser EA (1951) Interfacial tension at elevated pressure and temperature. II. Interfacial properties of hydrocarbon–water systems. J Phys Chem 55:408–421

Miller J, Rogowski M, Kelly W (2002) Using a CFD model to understand the fluid dynamics promoting E. coli breakage in a high-pressure homogenizer. Biotechnol Progress 18:1060–1067

Moelants KR, Lemmens L, Vandebroeck M, Van Buggenhout S, Van Loey AM, Hendrickx ME (2012) Relation between particle size and carotenoid bioaccessibility in carrot-and tomato-derived suspensions. J Agr Food Chem 60:11995–12003

Mohan S, Narsimhan G (1997) Coalescence of protein-stabilized emulsions in a high-pressure homogenizer. J Coll Int Sci 192:1–15

Mohr KH (1987) High-pressure homogenization. Part I. Liquid-liquid dispersion in turbulence fields of high energy density. J Food Eng 6:177–186

Moroni O, Jean J, Autret J, Fliss I (2002) Inactivation of lactococcal bacteriophages in liquid media using dynamic high pressure. Int Dairy J 12:907–913

Naidu DV, Rajan R, Kumar R, Gandhi KS, Arakeri VH, Chandrasekaran S (1994) Modelling of a batch sonochemical reactor. Chem Eng Sci 49:877–888

Nakayama Y (1964) Action of the fluid in the air-micrometer: 3rd report, characteristics of double-disc nozzle no. 1, in the case of compressibility being ignored. Bulletin of JSME 28:698–707

Navarro JL, Izquierdo L, Carbonell JV, Sentandreu E (2014) Effect of pH, temperature and maturity on pectinmethylesterase inactivation of citrus juices treated by high-pressure homogenization. LWT - Food Sci Technol 57:785–788

Orien V (2014) High pressure processing: opportunities to produce healthy food products and ingredients. New Food magazine. Issue 5. October 27

Panagiotou T, Fisher R (2012) Improving product quality with entrapped stable emulsions: from theory to industrial application. Challenges 3:84–113

Pandolfe WD (1982) Development of the new Gaulin micro-gap™ homogenizing valve. J Dairy Sci 65:2035–2044

Panozzo A, Lemmens L, Van Loey A, Manzocco L, Nicolo MC, Hendrickx M (2013) Microstructure and bioaccessibility of different carotenoid species as affected by high pressure homogenisation: a case study on differently coloured tomatoes. Food Chem 141:4094–4100

Patazca E, Koutchma T, Balasubramaniam VM (2007) Quasi-adiabatic temperature increase during high pressure processing of selected foods. J Food Eng 80:199–205

Pathanibul P, Taylor TM, Davidson PM, Harte F (2009) Inactivation of Escherichia coli and Listeria innocua in apple and carrot juices using high-pressure homogenization. Int J Food Microbiol 129:316–320

Phipps LW (1975) The fragmentation of oil drops in emulsions by a high-pressure homogenizer. J Phys D Appl Phys 8:448–462

Piorkowski DT, McClements JD (2014) Beverage emulsions: recent developments in formulation, production, and applications. Food Hydrocolloid 42:5–41

Poliseli-Scopel FH, Hernández-Herrero M, Guamis B, Ferragut V (2014) Sterilization and aseptic packaging of soymilk treated by ultra high pressure homogenization. Innov Food Sci Emerg 22:81–88

Ramaswamy HS, Awuah GB, Simpson BK (1997) Heat transfer and lethality considerations in aseptic processing of liquid/particle mixtures: a review. Crit Rev Food Sci Nutr 37:253–286

Rasanayagam V, Balasubramaniam VM, Ting E, Sizer CE, Bush C, Anderson C (2003) Compression heating of selected fatty food materials during high-pressure processing. J Food Sci 68:254–259

Rayner M, Dejmek P (2015) Engineering aspects of food emulsification and homogenization. CRC Press, Boca Raton

Rosa RMS (2006) Turbulence theories. In: Françoise JP, Naber GL, Tsun TS (eds) Encyclopedia of mathematical physics, 1st edn. Academic Press, Oxford

Rovinsky LA (1994) The analysis and calculation of the efficiency of a homogenizing valve. J Food Eng 23:429–448

Sandeep KP, Simunovic J (2005) Aseptic processing: basic principles and advantages. In: Hui YH (ed) Handbook of food science, technology, and engineering - 4 volume set. CRC Press Taylor & Francis Group, Boca Raton

Sastry SK, Cornelius BD (2002) Aseptic processing of foods containing solid particulates. Wiley, New York, NY

Schlender M, Spengler A, Schuchmann HP (2015a) High-pressure emulsion formation in cylindrical coaxial orifices: influence of cavitation induced pattern on oil drop size. Int J Multiphase Flow 74:84–95

Schlender M, Minke K, Spiegel B, Schuchmann HP (2015b) High-pressure double stage homogenization processes: influences of plant setup on oil droplet size. Chem Eng Sci 131:162–171

Schultz S, Wagner G, Urban K, Ulrich J (2004) High-pressure homogenization as a process for emulsion formation. Chem Eng Technol 27:361–368

Shirgaonkar IZ, Lothe RR, Pandit AB (1998) Comments on the mechanism of microbial cell disruption in high-pressure and high-speed devices. Biotechnol Progress 14:657–660

Smiddy MA, Martin JE, Huppertz T, Kelly AL (2007) Microbial shelf-life of high-pressure-homogenised milk. Int Dairy J 17:29–32

Stang M, Schuchmann H, Schubert H (2001) Emulsification in high-pressure homogenizers. Eng Life Sci 1:151–157

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, East Lansing

Stevenson MJ, Chen XD (1997) Visualization of the flow patterns in a high-pressure homogenizing valve using a CFD package. J Food Eng 33:151–165

Stone HA, Bentley BJ, Leal LG (1986) An experimental study of transient effects in the breakup of viscous drops. J Fluid Mech 173:131–158

Suárez-Jacobo Á, Rüfer CE, Gervilla R, Guamis B, Roig-Sagués AX, Saldo J (2011) Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice. Food Chem 127:447–454

Suslick KS, Mdleleni MM, Ries JT (1997) Chemistry induced by hydrodynamic cavitation. J Am Chem Soc 119:9303–9304

Svelander CA, Lopez-Sanchez P, Pudney PDA, Schumm S, Alminger MAG (2011) High pressure homogenization increases the in vitro bioaccessibility of α- and β-carotene in carrot emulsions but not of lycopene in tomato emulsions. J Food Sci 76:215–225

Tahiri I, Makhlouf J, Paquin P, Fliss I (2006) Inactivation of food spoilage bacteria and Escherichia coli O157: H7 in phosphate buffer and orange juice using dynamic high pressure. Food Res Int 39:98–105

Taisne L, Walstra P, Cabane B (1996) Transfer of oil between emulsion droplets. J Colloid Inter Sci 184:378–390

Taylor TM, Roach A, Black DG, Davidson PM, Harte F (2007) Inactivation of Escherichia coli K-12 exposed to pressures in excess of 300 MPa in a high-pressure homogenizer. J Food Prot 70:1007–1010

Tennekes H, Lumley JL (1972) A first course in turbulence. The MIT Press, Massachusetts, MA

Thiebaud M, Dumay E, Picart L, Guiraud JP, Cheftel JC (2003) High-pressure homogenisation of raw bovine milk. Effects on fat globule size distribution and microbial inactivation. Int Dairy J 13:427–439

Toro-Funes N, Bosch-Fusté J, Veciana-Nogués MT, Vidal-Carou MC (2014a) Effect of ultra high pressure homogenization treatment on the bioactive compounds of soya milk. Food Chem 152:597–602

Toro-Funes N, Bosch-Fusté J, Veciana-Nogués MT, Vidal-Carou MC (2014b) Changes of isoflavones and protein quality in soymilk pasteurised by ultra-high-pressure homogenisation throughout storage. Food Chem 162:47–53

Toro-Funes N, Bosch-Fusté J, Latorre-Moratalla ML, Veciana-Nogués MT, Vidal-Carou MC (2015) Isoflavone profile and protein quality during storage of sterilised soymilk treated by ultra high pressure homogenisation. Food Chem 167:78–83

Tribst AAL, Cristianini M (2012a) Changes in commercial glucose oxidase activity by high pressure homogenization. Innov Food Sci Emerg 16:355–360

Tribst AAL, Cristianini M (2012b) Increasing fungi amyloglucosidase activity by high pressure homogenization. Innov Food Sci Emerg 16:21–25

Tribst AAL, Cristianini M (2012c) High pressure homogenization of a fungi α-amylase. Innov Food Sci Emerg 13:107–111

Tribst AAL, Franchi MA, de Massaguer PR, Cristianini M (2011) Quality of mango nectar processed by high-pressure homogenization with optimized heat treatment. J Food Sci 76:M106–M110

Tribst AAL, Augusto PE, Cristianini M (2012d) The effect of high pressure homogenization on the activity of a commercial β-galactosidase. J Ind Microbiol Biotech 39:1587–1596

Tribst AAL, Augusto PE, Cristianini M (2013) Multi-pass high pressure homogenization of commercial enzymes: effect on the activities of glucose oxidase, neutral protease and amyloglucosidase at different temperatures. Innov Food Sci Emerg 18:83–88

Tribst AAL, Cota J, Murakami MT, Cristianini M (2014) Effects of high pressure homogenization on the activity, stability, kinetics and three-dimensional conformation of a glucose oxidase produced by Aspergillus niger. PloS one 9:e103410

Vachon JF, Kheadr EE, Giasson J, Paquin P, Fliss I (2002) Inactivation of foodborne pathogens in milk using dynamic high pressure. J Food Protec 65:345–352

van Boekel M, Fogliano V, Pellegrini N, Stanton C, Scholz G, Lalljie S, Somoza V, Knorr D, Jasti PR, Eisenbrand G (2010) A review on the beneficial aspects of food processing. Mol Nurt Food Res 54:1215–1247

Vannini L, Lanciotti R, Baldi D, Guerzoni ME (2004) Interactions between high pressure homogenization and antimicrobial activity of lysozyme and lactoperoxidase. Int J Food Microbiol 94:123–135

Velázquez-Estrada RM, Hernández-Herrero MM, Guamis-López B, Roig-Sagués AX (2012) Impact of ultra high pressure homogenization on pectin methylesterase activity and microbial characteristics of orange juice: a comparative study against conventional heat pasteurization. Innov Food Sci Emerg 13:100–106

Velázquez-Estrada RM, Hernández-Herrero MM, Rüfer CE, Guamis-López B, Roig-Sagués AX (2013) Influence of ultra high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice. Innov Food Sci Emerg 18:89–94

Walstra P (1993) Principles of emulsion formation. Chem Eng Sci 48:333–349

Watson E (2012) Could HPP be the secret weapon in the battle to reduce sodium? Date published May 29, 2012. www.foodnavigator.com. Last accessed March 10, 2015

Welti-Chanes J, Ochoa-Velasco CE, Guerrero-Beltrán JA (2009) High-pressure homogenization of orange juice to inactivate pectinmethylesterase. Innov Food Sci Emerg 10:457–462

Wuytack EY, Diels AM, Michiels CW (2002) Bacterial inactivation by high-pressure homogenisation and high hydrostatic pressure. Int J Food Microbiol 77:205–212

Yu Y, Xu Y, Wu J, Xiao G, Fu M, Zhang Y (2014) Effect of ultra-high pressure homogenisation processing on phenolic compounds, antioxidant capacity and anti-glucosidase of mulberry juice. Food Chem 153:114–120

Zamora A, Guamis B (2015) Opportunities for ultra-high-pressure homogenisation (UHPH) for the food industry. Food Eng Rev 7:130–142

Zhang H, Barbosa-Canovas GV, Balasubramaniam VM, Dunne CP, Farkas DF, Yuan JTC (2011) Nonthermal processing technologies for food. Wiley-Blackwell, Oxford

Acknowledgements

Research support for OSU Food Safety Engineering Laboratory (http://u.osu.edu/foodsafetyeng/) provided, in part, by USDA National Institute for Food and Agriculture HATCH project, Ohio Agricultural Research and Development Corporation (OARDC), and the food industry. References to commercial products or trade names are made with the understanding that no endorsement or discrimination by The Ohio State University is implied.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martínez-Monteagudo, S.I., Yan, B. & Balasubramaniam, V.M. Engineering Process Characterization of High-Pressure Homogenization—from Laboratory to Industrial Scale. Food Eng Rev 9, 143–169 (2017). https://doi.org/10.1007/s12393-016-9151-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-016-9151-5