Abstract

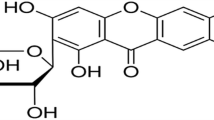

In this study, natural dyes were extracted from five plants, namely diospyros kaki, dioscorea cirrhosa, millettia (jixueteng), ecliptae, and macrocarpa nucuma, using environmentally-friendly solvents, including ethanol and deionized (DI) water. A plant mordant, tannin extracted from Emblica officinalis G., and a metal mordant, copper sulfate, were used in the pre-dyeing process. Cotton and silk fabric samples were treated using the five natural dyes without and with mordanting for comparison on their color strength and characteristics as well as protection against ultraviolet radiation (UVR). Results revealed that Emblica officinalis G. had the highest total phenol content, followed by dioscorea cirrhosa. The presence of abundant phenolic groups in the natural dyes and mordant makes them effective coloration agents for fabrics. Cotton and silk fabrics dyed using ecliptae without pre-mordanting had the highest K/S values. Silk fabrics had higher K/S values than cotton fabrics, indicating greater color strength in pre-mordanted silk treated with DI water-extracted dyes. Natural mordant used before treatment with natural dyes contribute to significant enhancement in color strength, and Emblica officinalis G. alone could darken the color of cotton and silk fabrics dyed with plant pigment. Moreover, treatment with natural dyes after mordanting can increase ultraviolet protection factor (UPF) and the enhancement in UVR protection is greater and more significant in cotton fabrics than in silk fabrics, and in fabrics treated with DI water-extracted natural dyes than in those treated with ethanol-extracted ones. In conclusion, pre-dyeing with natural mordant followed by treatment with natural dyes extracted using environmentally-friendly solvents can enhance significantly K/S and UPF, offering directions for manufacturing textiles without environmental hazards but with good appearance and health benefits.

Similar content being viewed by others

References

E. Forgacs, T. Cserháti, and G. Oros, Environ. Int., 30, 953 (2004).

C. Gupta, D. Sharma, S. Aggarwal, and N. Nagpal, I.J.S.N., 4, 351 (2013).

S. Komboonchoo and T. Bechtold, J. Cleaner Prod., 17, 1487 (2009).

C. Boga, C. Delpivo, B. Ballarin, M. Morigi, S. Galli, G. Micheletti, and S. Tozzi, Dyes Pigm., 97, 9 (2013).

O. Avinc, A. Celik, G. Gedik, and A. Yavas, Fiber. Polym., 14, 866 (2013).

V. S. Borland, America’s Textile Industries, 29, 66 (2000).

T. Bechtold and R. Mussak, “Handbook of Natural Colorants”, Wiley, 2009.

D. Cristea and G. Vilarem, Dyes Pigm., 70, 238 (2006).

M. Choi, Y. Shin, and D. I. Yoo, Fiber. Polym., 14, 2032 (2013).

S. Y. Kamat and D. V. Alat, Indian Text. J., 100, 66 (1990).

G. Dalby, Color. Technol., 109, 8 (1993).

K. H. Prabhu, M. D. Teli, and N. G. Waghmare, Fiber. Polym., 12, 753 (2011).

A. Cho, Y. Shin, and D. Yoo, J. Kor. Soc. Dyers Finishers, 20, 42 (2008).

A. D. Broadbent, “Basic Principles of Textile Coloration”, The Society of Dyers and Colorists, 2001.

E. Haslam, “Plant Polyphenols: Vegetable Tannins Revisited”, Cambridge University Press, 1989.

L. Capjack, N. Kerr, S. Davis, R. Fedosejevs, K. L. Hatch, and N. L. Markee, Family and Consumer Sciences, 23, 198 (1994).

M. Pailthorpe, Mutat. Res., 422, 175 (1998).

R. P. Gallagher and T. K. Lee, Prog. Biophys. Mol. Biol., 92, 119 (2006).

A. V. Parisi, M. G. Kimlin, L. R. Meldrum, and C. M. Relf, Radiat. Prot. Dosim., 86, 69 (1999).

D. Grifoni, L. Bacci, G. Zipoli, L. Albanese, and F. Sabatini, Dyes Pigm., 91, 279 (2011).

A. K. Sarkar, BMC Dermatology, 4, 15 (2004).

V. L. Singleton, R. Orthofer, and R. M. Lamuela Raventos, Method. Enzymol., 299, 152 (1999).

J. N. Ettersand and M. D. Hurwitz, Text. Chem. Color., 18, 19 (1986).

A. K. Sarkar and C. M. Seal, Cloth. Text. Res. J., 21, 162 (2003).

AS/NZS 4399-1996, Australian/New Zealand Standard, 1996.

H. P. Gies, C. R. Roy, G. Elliot, and Z. Wang, Health Phys., 67, 131 (1994).

K. L. Hatch, AATCC Review, 3, 23 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chao, Yc., Ho, Th., Cheng, Zj. et al. A study on combining natural dyes and environmentally-friendly mordant to improve color strength and ultraviolet protection of textiles. Fibers Polym 18, 1523–1530 (2017). https://doi.org/10.1007/s12221-017-6964-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-6964-7