Abstract

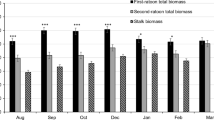

Sugarcane sugar and bagasse can be utilized for the production of ethanol or other biofuels. A better understanding of the changes in composition with development along the stalk and with crop development will maximize the usage of sugarcane for this purpose. Two experiments were designed to elucidate internode composition changes during the growing season. In experiment 1, an internode of stalks of 5 modern cultivars were marked at the start of elongation, and then sampled every 1 to 2 weeks from July until October. Sugars were extracted and assayed, and a sequential detergent method was used to estimate hemicellulose, cellulose, and lignin contents. In experiment 2, internodes 1, 3, 5, 7, 9, and 11 down the stalk were sampled in late July (grand growth) and late September (ripening). Internode length, fresh weight, dry weight, water content, and sugar contents were determined as well as cell wall composition. Both experiments were repeated in 2 years. As internodes elongated, total sugar increased, and hemicellulose decreased as a proportion of neutral detergent fiber, while cellulose and lignin increased. After elongation, sucrose and lignin increased, and cellulose content decreased with internode age. The variability in cell wall composition among the five cultivars suggests that selection for desirable composition may be possible. In Experiment 2, hemicellulose contents were lower, and lignin and ash contents were higher at ripening than during grand growth. Delaying sugarcane harvest to maximize sucrose content may decrease bagasse suitability for cellulosic ethanol production because of the increased lignin content.

Similar content being viewed by others

Abbreviations

- SDS:

-

Sodium lauryl sulfate

- EDTA:

-

Ethylene diamine tetraacetic acid

- CTAB:

-

Cetyl trimethylammonium bromide

- NDF:

-

Neutral detergent fiber

- ADF:

-

Acid detergent fiber

- ADL:

-

Acid detergent lignin

- FW:

-

Fresh weight

- DW:

-

Dry weight

- NIRS:

-

Near-infrared reflectance spectroscopy

References

Alexander AG (1987) Production of sugarcane for energy. Sugar J 49:5–7

Berding N, Brotherton GA, le Brocq DG, Skinner JC (1991) Near infrared reflectance spectroscopy for analysis of sugarcane from clonal evaluation trials: I. Fibrated cane. Crop Sci 31:1017–1023

Berding N, Brotherton GA, le Brocq DG, Skinner JC (1991) Near infrared reflectance spectroscopy for analysis of sugarcane from clonal evaluation trials: II. Expressed juice. Crop Sci 31:1024–1028

Bischoff KP, Gravois KA, Reagan TE, Hoy JW, LaBorde CM, Kimbeng CA et al (2009) Registration of ‘L 99-226’ Sugarcane. J Plant Reg 3:241–247

Boudet A-M (2003) Toward an understanding of the supramolecular organization of the lignified wall. In: Rose JKC (ed) The plant cell wall, vol 8. CRC, Boca Raton, pp 155–182

Cardona CA, Quintero JA, Paz IC (2010) Production of bioethanol from sugarcane bagasse: status and perspectives. Bioresour Technol 101:4754–4766

Clements HF, Shigeura H, Akamine EK (1952) Factors affecting the growth of sugar cane.Technical Bulletin No. 18. University of Hawaii Agricultural Experiment Station, Aiea, HI

Cock JH, Luna CA, Palma A (2000) The trade-off between total harvestable production and concentration of the economically useful yield component: cane tonnage and sugar content. Field Crop Res 67:257–262

Drummond AR, Drummond IW (1996) Pyrolysis of sugar cane bagasse in a wire-mesh reactor. Ind Eng Chem Res 35:1263–1268

Eggleston G, Grisham M, Antoine A (2009) Clarification properties of trash and stalk tissues from sugar cane. J Agric Food Chem 58:366–373

Erlich C, Öhman M, Björnbom E, Fransson TH (2005) Thermochemical characteristics of sugar cane bagasse pellets. Fuel 84:569–575

Goering HK, Van Soest PJ (1970) Forage fiber analysis (apparatus, reagents, procedures, and some applications). Agricultural Research Service, US Dept of Agriculture, Washington, D.C

Gravois KA, Bischoff KP, Milligan SB, Martin FA, Hoy JW, Reagan TE et al (2008) Registration of ‘L 97-128’ Sugarcane. J Plant Registrations 2:24–28

Gravois KA, Legendre BL (2011) The 2010 Louisiana sugarcane variety survey. Sugar Bulletin 89:27–30, 32

Gudoshnikov S (2009) Bagasse-based cogeneration—an industry overview. Int Sugar J 111:560–565

Hatfield RD, Jung HJG, Ralph J, Buxton DR, Weimer PJ (1994) A comparison of the insoluble residues produced by the klason lignin and acid detergent lignin procedures. J Sci Food Agric 65:51–58

Jacobsen KR, Fisher DG, Maretzki A, Moore PH (1992) Developmental changes in the anatomy of the sugarcane stem in relation to phloem unloading and sucrose storage. Bot Acta 105:70–80

Jung HG, Casler MD (2006) Maize stem tissues: cell wall concentration and composition during development. Crop Sci 46:1793–1800

Kim M, Day DF (2011) Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar mills. J Ind Microbiol Biotechnol 38:803–807

Lingle SE (1997) Seasonal internode development and sugar metabolism in sugarcane. Crop Sci 37:1222–1227

Lingle SE (1999) Sugar metabolism during growth and development in sugarcane internodes. Crop Sci 39:480–486

Lingle SE (1999) Sugarcane. In: Smith DL (ed) Crop yield, physiology and processes. Springer, Berlin, pp 287–310

Lingle SE, Smith RC (1991) Sucrose metabolism related to growth and ripening in sugarcane internodes. Crop Sci 31:172–177

Lingle SE, Tew TL (2008) A comparison of growth and sucrose metabolism in sugarcane germplasm from Louisiana and Hawaii. Crop Sci 48:1155–1163

Lingle SE, Viator RP, Johnson RM, Tew TL, Boykin DL (2009) Recurrent selection for sucrose content has altered growth and sugar accumulation in sugarcane. Field Crop Res 113:306–311

Moore PH (1987) Anatomy and morphology. In: Heinz DJ (ed) Sugarcane improvement through breeding. Elsevier, Amsterdam, pp 85–142

Moore PH, Jacobsen KR (1992) Biophysical and structural changes in sugarcane stalk storage tissue during development: a role in regulating sucrose storage? In: Wilson JR (ed) Improvement of yield in sugar cane through increased sucrose accumulation. CSIRO, Brisbane, pp 71–75

Muir BM, Eggleston G, Barker B (2009) The effect of green sugarcane on downstream processing at two Midlands factories. SIMRI Rep 2051:1–34

Renewable Fuels Association (2010) Statistics. http://www.ethanolrfa.org/pages/statistics#E

Tew TL, Cobill RM (2008) Genetic improvement of sugarcane (Saccharum spp.) as an energy crop. In: Vermerris W (ed) Genetic improvement of bioenergy crops. Springer, New York, pp 249–272

Tew TL, Dufrene EO, Garrison DD, White WH, Grisham MP, Pan YB et al (2009) Registration of ‘HoCP 00-950’ sugarcane. J Plant Registrations 3:42–50

Tew TL, White WH, Legendre BL, Grisham MP, Dufrene EO, Garrison DD et al (2005) Registration of ‘HoCP 96-540’ sugarcane. Crop Sci 45:785–786

Van Soest PJ, Robertson JB (1980) Systems of analysis for evaluating fibrous feeds. In: Pigden WJ, Balch CC, Graham M (eds) Standardization of Analytical Methodology for Feeds, Int. Res. Dev. Ctr., Ottawa, ON pp 49–60

Viator RP, Johnson RM, Boykin DL, Richard EP Jr (2009) Sugarcane postharvest residue management in a temperate climate. Crop Sci 49:1023–1028

Vogel KP, Pedersen JF, Masterson SD, Toy JJ (1999) Evaluation of a filter bag system for NDF, ADF, and IVDMD forage analysis. Crop Sci 39:276–279

Acknowledgments

The authors would like to thank April Allen, Gwen Mullaney, and Scottie Sklanka for their assistance with these experiments. Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lingle, S.E., Thomson, J.L. Sugarcane Internode Composition During Crop Development. Bioenerg. Res. 5, 168–178 (2012). https://doi.org/10.1007/s12155-011-9153-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-011-9153-3