Abstract

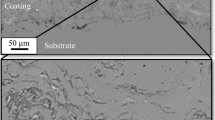

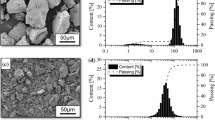

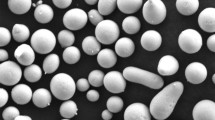

In terms of arc-sprayed coatings, the lamellar coating microstructure is mainly affected by the atomization behavior of the molten electrode tips. When using compressed air, oxide formations occur during atomization, across the particle-laden spray plume and when the molten droplets splash onto the substrate. Within the scope of this study, the potential of a high-velocity arc-spraying process due to elevated atomization gas pressures and its effect on the spray and coating characteristics was analyzed using a cast tungsten carbide (CTC)-reinforced FeCMnSi cored wire. Since the atomization behavior corresponds with the electrode phenomena, the power spectrum and the droplet formation were observed during spraying. The tribo-mechanical properties of CTC-FeCMnSi coatings were examined in dry sliding experiments and indentation tests. In addition, adhesion tests and metallographic investigations were carried out to analyze the bonding strength, cohesive behavior, and lamellar microstructure. The occurrence of oxide phases was evaluated by x-ray diffraction and electron microscopy. Moreover, the oxygen content was determined by using glow discharge optical emission spectroscopy as well as energy-dispersive x-ray spectroscopy. With respect to elevated atomization gas pressures, a dense microstructure with improved adhesion to the substrate and reduced surface roughness was observed. Dry sliding experiments revealed an advanced wear behavior of specimens, when using above average increased atomization gas pressures. Analytic methods verified the existence of oxide phases, which were generated during spraying. A significant change of the extent and type of oxides, when applying an increased flow rate of the atomization gas, cannot be observed. Besides an enhanced coating quality, the use of increased atomization gas pressure exhibited good process stability.

Similar content being viewed by others

References

J. Wilden, A. Wank, F. Schreiber, Wires for Arc- and High Velocity Flame Spraying—wire design, Materials and Coatings Properties, in Thermal Spray: Surface Engineering Via Applied Research ed. by C.C. Berndt, May 8-11, 2000 (Montréal, Québec, Canada), ASM International, 2000, p 609-617

A. Pourmousa, J. Abedini, S. Mostaghimi, and S. Chandra, Particle Diagnostics in Wire-Arc Spraying System, in Thermal Spray 2004: Advances in Technology and Application, ASM International, May 10-12, 2004 (Osaka, Japan), ASM International, 2004, p 962-968

M.P. Planche, H. Liao, and C. Coddet, Relationships Between In-Flight Particle Characteristics and Coating Microstructure with a Twin Wire Arc Spray Process and Different Working Conditions, Surf. Coat. Technol., 2004, 182, p 215-226

H. Jandin, H. Liao, Z.Q. Feng, and C. Coddet, Correlations Between Operating Conditions, Microstructure and Mechanical Properties of Twin Wire Arc Sprayed Steel Coatings, Mater. Sci. Eng., 2003, 349, p 298-305

X. Wang, D. Zhuang, E. Pfender, J. Heberlein, and W. Gerberich, Effect of Atomizing Gas Pressure on Coating Properties in Wire Arc Spray, in Thermal Spray Industrial Applications, ed. by C.C. Berndt, S. Sampath, June 20-24, 1994 (Boston, MA), ASM International, 1994, p 587-592

T. Watanabe, X. Wang, E. Pfender, and J. Heberlein, Correlations Between Electrode Phenomena and Coating Properties in Wire Arc Spraying, Thin Solid Films, 1998, 316(1-2), p 169-173

A.P. Newbery and P.S. Grant, Large Arc Voltage Fluctuations and Droplet Formation in Electric Arc Wire Spraying, Powder Metall., 2003, 46(3), p 229-235

R. Bolot, M.P. Planche, H. Liao, and C. Coddet, A Three-Dimensional Model of the Wire-Arc Spray Process and Its Experimental Validation, J. Mater. Process. Tech., 2008, 200, p 94-105

X. Wang, J. Heberlein, W. Gerberich, and E. Pfender, Effect of Shrouded CO2 Gas Atomization on Coating Properties in Wire Arc Spray, in Advances in Thermal Spray Science and Technology, ed. by C.C. Berndt, S. Sampath, Sept 11-15, 1995 (Houston, TX), ASM International, 1995, p 31-37

M. Kelkar, N. Hussary, J. Schein, and J. Heberlein, Optical Diagnostics and Modeling of Gas and Droplet Flow in Wire Arc Spraying, in Thermal Spray: Meeting the Challenges of the 21st Century, ed. by C. Coddet, May 25-29, 1998 (Nice, France), ASM International, 1998, p 329-334

H. Liao, Y.L. Zhu, R. Bolot, C. Coddet, and S.N. Ma, Size Distribution of Particles from Individual Wires and Effects of Nozzle Geometry in Twin Wire Arc Spraying, Surf. Coat. Technol., 2005, 200, p 2123-2130

X. Wang, J. Heberlein, E. Pfender, and W. Gerberich, Effect of Nozzle Configuration, Gas Pressure, and Gas Type on Coating Properties in Wire Arc Spray, J. Therm. Spray Technol., 1999, 8(4), p 565-575

J. Wilden, A. Schwenk, and J.P. Bergmann, Supersonic Nozzles of the Wire Arc Spraying, Thermal Spray 2005, in Thermal Spray Connects: Explore Its Surfacing Potential!, ed. by E. Lugscheider, May 2-4, 2005 (Basel, Switzerland), DVS-German Welding Society, 2005, p 1068-1073

J. Wilden, Virtuelles Werkstoff- und Prozessdesign funktionaler Schichten, Materialwissenschaften und Werkstofftechnik, 2007, 38(2), p 131-138

G. Paczkowski, C. Rupprecht, and B. Wielage, High-Velocity Arc Spraying—The Renaissance of a Coating Process, Therm. Spray Bull., 2012, 2, p 140-147

Y. Chen, X. Liang, and Y. Liu, Optical Design of Wire Arc Spray Gun Based on Finite Element Modeling, J. Beijing Univ. Technol., 2011, 37(2), p 253-259

S.L. Toma, C. Bejinariu, R. Baciu, and S. Radu, The Effect of Frontal Nozzle Geometry and Gas Pressure on the Steel Coating Properties Obtained By Wire Arc Spraying, Surf. Coat. Technol., 2013, 220, p 266-270

A.P. Newbery, P.S. Grant, and R.A. Neiser, The Velocity and Temperature of Steel Droplets During Electric Arc Spraying, Surf. Coat. Technol., 2005, 195(23), p 91-101

I. Gedzevicius and A.V. Valiulis, Analysis of Wire Arc Spraying Process Variables on Coatings Properties, J. Mater. Process. Tech., 2006, 175(1-3), p 206-211

A.L. Horner, A.C. Hall, and J.F. McCloskey, The Effect of Process Parameters on Twin Wire Arc Spray Pattern Shape, Coatings, 2015, 5, p 115-123

A. Pourmousa, J. Mostaghimi, A. Abdini, and S. Chandra, Particle Size Distribution in a Wire-Arc Spraying System, J. Therm. Spray Technol., 2005, 14(4), p 502-510

W. Tillmann, E. Vogli, M. Abdulgader, M. Gurris, D. Kuzmin, and S. Turek, Particle Behavior During the Arc Spraying Process with Cored Wires, J. Therm. Spray Technol., 2008, 17(5–6), p 966-973

A.P. Newbery, T. Rayment, and P.S. Grant, A Particle Image Velocimetry Investigation of In-Flight and Deposition Behaviour of Steel Droplets During Electric Arc Spray Forming, Mater. Sci. Eng., 2004, 383, p 137-145

W. Tillmann and M. Abdulgader, Wire Composition, its Effect on Metal Disintegration and Particle Formation in Twin-Wire Arc-Spraying Process, J. Therm. Spray Technol., 2013, 22(2-3), p 352-362

D.J. He, B.J. Fu, J.M. Jiang, and X.J. Li, Microstructure and Wear Performance of Arc Sprayed Fe-FeB-WC Coatings, J. Therm. Spray Technol., 2008, 17(5), p 757-761

B. Xu, Z. Zhu, S. Ma, W. Zhang, and W. Liu, Sliding Wear Behavior of Fe-Al and Fe-Al/WC Coatings Prepared by High Velocity Arc Spraying, Wear, 2004, 257, p 1089-1095

W. Tillmann, B. Klusemann, J. Nebel, and B. Svendsen, Analysis of the Mechanical Properties of an Arc-Sprayed WC-FeCSiMn Coating: Nanoindentation and Simulation, J. Therm. Spray Technol., 2011, 20(1-2), p 328-335

W. Tillmann, W. Luo, and J. Nebel, Einfluss der Hartstoffkorngröße auf die tribologischen Eigenschaften gewalzter und geschliffener WSC-FeCSiMn-Schichten, Therm. Spray Bull., 2011, 4(1), p 56-63

W. Tillmann, W. Luo, and U. Selvadurai, Wear Analysis of Thermal Spray Coatings on 3D Surfaces, J. Therm. Spray Technol., 2014, 23(1-2), p 245-251

W. Tillmann and B. Krebs, Influence of Handling Parameters on Coating Characteristics in Order to Produce Near-Net-Shape Wear Resistant Coatings, J. Therm. Spray Technol., 2012, 21(3), p 644-650

W. Tillmann, and B. Krebs, Robotergestützte, Konturgenaue Bauteilbeschichtung für den Verschleißschutz mittels Thermischer Spritzverfahren, in Tagungsband, 14. Werkstofftechnisches Kolloquium, 43, B. Wielage, Ed., Sept 1–2, 2011 (Chemnitz, Germany), Schriftenreihe Werkstoffe und werkstofftechnische Anwendungen, Chemnitz: Eigenverl, 2011, p 13-23

W. Tillmann, B. Hussong, T. Priggemeier, S. Kuhnt, N. Rudak, and H. Weinert, Influence of Parameter Variations on WC-Co Splat Formation in an HVOF Process Using a New Beam-Cutter Device, J. Therm. Spray Technol., 2013, 22(2-3), p 250-262

C. Krywka, M. Paulus, C. Sternemann, M. Volmer, A. Remhof, G. Nowak, A. Nefedov, B. Pöter, M. Spiegel, and M. Tolan, The New Diffractometer for Surface X-ray Diffraction at Beamline BL9 of DELTA, J. Synchrotron Radiat., 2006, 13, p 8-13

A.P. Hammersley, S.O. Svensson, and A. Thompson, Calibration and Correction of Spatial Distortions in 2D Detector Systems, Nucl. Instr. Meth., 1994, A346, p 312-321

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564-1583

B. Krebs, Konturgenaue Bauteilbeschichtung für den Verschleißschutz mittels atmosphärischen Plasmaspritzens und Lichtbogenspritzens (in German), Ph.D. Thesis, TU Dortmund University, 2011

E.A.M. Elshafei, M.S. Mohamed, H. Mansour, and M. Sakr, Experimental Study of Heat Transfer in Pulsating Turbulent Flow in a Pipe, Int. J. Heat Fluid F, 2008, 29(4), p 1029-1038

R. Wiberg and N. Lior, Heat Transfer from a Cylinder in Axial Turbulent Flows, Int. J. Heat Mass Tranf., 2005, 48(8), p 1505-1517

N. Masoumifard, N. Mostoufi, A.A. Hamidi, and R. Sotudeh-Gharebagh, Investigation of Heat Transfer Between a Horizontal Tube and Gas–Solid Fluidized Bed, Int. J. Heat Fluid F, 2008, 29(5), p 1504-1511

G. Paczkowski, The New Old Way—High-Velocity Arc Spraying Allows New Perspectives & Process Diagnostics in Open Wire Arc Spraying, in Colloquium High Velocity Oxy-Fuel Flame Spraying, 9, C. Penszior, Ed., November 8-9, 2012 (Erding, Germany), Unterschleißheim: Gemeinschaft Thermisches Spritzen c/o Linde AG, 2012, p 139-150

W. Tillmann, M. Abdulgader, N. Anjami, and L. Hagen, Studying the Effect of the Air-Cap Configuration in Twin-Wire Arc-Spraying Process on the Obtained Flow Characteristics Using Design of Experiment Oriented Fluid Simulation, J. Therm. Spray Technol., 2015, 24(1-2), p 46-54

V. Boronenkov and Y. Korobov, Fundamentals of Arc Spraying: Physical and Chemical Regularities, Springer, Switzerland, 2015

J. Musil, F. Kunc, H. Zeman, and H. Poláková, Relationships Between Hardness, Young’s Modulus and Elastic Recovery in Hard Nanocomposite Coatings, Surf. Coat. Technol., 2002, 154, p 304-313

F. Cai, X. Huang, and Q. Yang, Mechanical Properties, Sliding Wear and Solid Particle Erosion Behaviors of Plasma Enhanced Magnetron Sputtering CrSiCN Coating Systems, Wear, 2015, 324–325, p 27-35

A. Portinha, V. Teixeira, J. Carneiro, M.G. Beghi, C.E. Bottani, N. Franco, R. Vassen, D. Stoever, and A.D. Sequeira, Residual Stresses and Elastic Modulus of Thermal Barrier Coatings Graded in Porosity, Surf. Coat. Technol., 2004, 188-189, p 120-128

E. Celik and O. Sarikaya, The Effect on Residual Stresses of Porosity in Plasma Sprayed MgO-ZrO2 Coatings for an Internal Combustion Diesel Engine, Mater. Sci. Eng., A, 2004, 379, p 11-16

S. Matthews and M. Schweizer, Optimization of Arc-Sprayed Ni-Cr-Ti Coatings for High Temperature Corrosion Applications, J. Therm. Spray Technol., 2013, 22(4), p 538-550

B.G. Gubenko et al., Structural Heterogeneity of Arc-Sprayed Grade 65G Steel Coating, Avt. Svarka, 1990, 6, p 19-23

A.H. Jay, and K.W. Andrews, Note on Oxide Systems Pertaining to Steel - Making Furnace Slags: FeO–MnO, FeO–MgO, CaO–MnO, MgO–MnO, J. Iron Steel Inst., 1946, 152, p 15-18. (Calculated from ICSD using POWD-12++(1997))

D. Schulz, and G. McCarthy, North Dakota State University, Fargo, North Dakota, USA., ICDD Grant-in-Aid, 1987

M.C. Morris, H.F. McMurdie, E.H. Evans, B. Paretzkin, H.S. Parker, and N.C. Panagiotopoulos, Standard X-ray Diffraction Powder Patterns Section 18: Data for 58 Substances, Natl. Bur. Stand. (U.S.) Monogr., 1981, 25(18), p 37

B. Andersson and J.O. Sleines, Decomposition and Ordering in Fe1-x O, Acta Crystallogr. Sect., 1977, A33(2), p 268-276 ((Calculated from ICSD using POWD-12++))

N.C. Tombs and H.P. Rooksby, Structure Transition and Antiferromagnetism in Magnetite, Acta Crystallogr., 1951, 4(5), p 474-475 ((Calculated from NIST using POWD-12++))

E. Tronc, C. Chaneac, and J. Jolivet, Structural and Magnetic Characterization of ε-Fe2O3, J. Solid State Chem., 1998, 139(1), p 93-104

A.P. Newbery and P.S. Grant, Oxidation During Electric Arc Spray Forming of Steel, J. Mater. Process. Tech., 2006, 178(1-3), p 259-269

B. Wielage et al., Iron-Based Coatings Arc-Sprayed with Cored Wires for Applications at Elevated Temperatures, Surf. Coat. Technol., 2013, 220, p 27-35

Acknowledgments

The authors gratefully acknowledge the financial support of the DFG (German Research Foundation) within the Collaborative Research Centre SFB 708 subproject A1. The authors thank the DELTA machine group for providing the synchrotron radiation and technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tillmann, W., Hagen, L. & Kokalj, D. Spray Characteristics and Tribo-Mechanical Properties of High-Velocity Arc-Sprayed WC-W2C Iron-Based Coatings. J Therm Spray Tech 26, 1685–1700 (2017). https://doi.org/10.1007/s11666-017-0605-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0605-y