Abstract

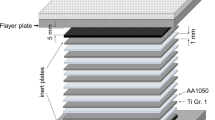

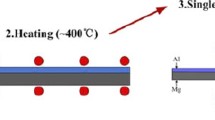

A 5083 Al/1060 Al/AZ31 composite plate was fabricated by explosive welding. The microstructure and properties of the composite plate were investigated after explosive welding. The results showed that all bonding interfaces were wavy interfaces. With an increasing distance from the detonation point, the wavelength and the amplitude also increased. The EDS results indicated that a 5-μm diffusion layer was observed at the 1060 Al/AZ31 layer, including the Mg2Al3 phase. Adiabatic shear bands and twin structures were observed in AZ31. The shear bond strength of the 5083 Al/1060 Al interface was 60 MPa, and the shear bond strength of the 1060 Al/AZ31 interface was 84 MPa.

Similar content being viewed by others

References

B.L. Mordike and T. Ebert, Magnesium Properties—Applications—Potential, Mater. Sci. Eng. A, 2001, 302, p 37–45

F. Findik, Recent Developments in Explosive Welding, Mater. Des., 2011, 32, p 1081–1093

N. Zhang, W. Wang, and X. Cao, The Effect of Annealing on the Interface Microstructure and Mechanical Characteristics of AZ31B/AA6061 Composite Plates Fabricated by Explosive Welding, Mater. Des., 2015, 65, p 1100–1109

Y.B. Yan, Z.W. Zhang, W. Shen, J.H. Wang, L.K. Zhang, and B.A. Chin, Microstructure and Properties of Magnesium AZ31B-Aluminum 7075 Explosively Welded Composite Plate, Mater. Sci. Eng. A, 2010, 527, p 2241–2245

Q. Wu and S. Yang, Microstructure and Properties of Bonding Interface in Explosive Welded AZ31/1060 Composite Plate, Chin. J. Rare Met., 2016, 40(10), p 996–1001 (in Chinese)

P. Chen, J. Feng, Q. Zhou, E. An, J. Li, Y. Yuan, and O. Sanli, Investigation on the Explosive Welding of 1100 Aluminum Alloy and AZ31 Magnesium Alloy, JMEPEG, 2016, 25, p 2635–2641

Q. Wu, Study on Welding Technology of Magnesium Alloy/Aluminum Alloy Composite Plate. Beijing Institute of Technology, Beijing, Master research, 2016 (in Chinese)

Clad Steel Plates—Mechanical and Technological Test, GB/T 6396-2008, PRC National Standard, 2008, Part 6, p 4

A.S. Bahrani, T.J. Black, and B. Crossland, The Mechanics of Wave Formation in Explosive Welding, Math. Phys. Sci., 1967, 296, p 123–136

Y. Zheng, Z. Luo, Q. Zhang, and W. Qi, Metals Physics Mechanism on the Wave Formation in the Bonding Zone of Explosive Welding II. Interaction Between the External Cause and the Internal Cause, J. Guangdong Non Ferr. Met., 1998, 8(2), p 131–139 (in Chinese)

B. Wronka, Testing of Explosive Welding and Welded Joint: Joint Mechanism and Properties of Explosive Welded Joints, J. Mater. Sci., 2010, 45, p 4078–4083

V.I. Lysak and S.V. Kuzmin, Lower Boundary in Metal Explosive Welding. Evolution of Ideas, J. Mater. Process. Technol., 2012, 212, p 150–156

H.R. Zareie Rajani and S.A.A. Akbari Mousavi, The Effect of Explosive Welding Parameters on Metallurgical and Mechanical Interfacial Features of Inconel 625/Plain Carbon Steel Bimetal Plate, Mater. Sci. Eng. A, 2012, 556, p 454–464

B. Gulenc, Investigation of Interface Properties and Weldability of Aluminum and Copper Plates by Explosive Welding Method, Mater. Des., 2008, 29, p 275–278

N. Kahraman, B. Gulenc, and F. Findik, Joining of Titanium/Stainless Steel by Explosive Welding and Effect on Interface, J. Mater. Process. Technol., 2005, 169, p 127–133

M. Acarer, B. Gulenc, and F. Findik, Investigation of Explosive Welding Parameters and Their Effects on Microhardness and Shear Strength, Mater. Des., 2003, 24, p 659–664

A. Durgutlu, H. Okuyucu, and B. Gulenc, Investigation of Effect of the Stand-off Distance on Interface Characteristics of Explosively Welded Copper and Stainless Steel, Mater. Des., 2008, 29, p 1480–1484

M. Acarer, B. Gulenc, and F. Findik, The Influence of Some Factors on Steel/Steel Bonding Quality on Their Characteristics of Explosive Welding Joints, J. Mater. Sci., 2009, 39, p 6457–6466

Acknowledgments

This work was supported by the National Natural Sciences Foundation of China (No. 51571031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, S., Bao, J. Microstructure and Properties of 5083 Al/1060 Al/AZ31 Composite Plate Fabricated by Explosive Welding. J. of Materi Eng and Perform 27, 1177–1184 (2018). https://doi.org/10.1007/s11665-018-3174-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3174-4