Abstract

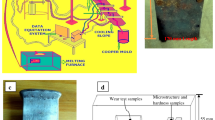

In the present study, Al6061-based alloy and composites were produced using powder metallurgy route. Two different kinds of base powders (prealloyed and premixed 6061Al alloy) were mixed with TiB2 particles in compositions ranging from 0 to 15 vol.%, respectively. The processed powders were compacted at 300 MPa and sintered at 620 °C under N2 atmosphere. The microstructural evolution of prealloyed and premixed 6061Al alloy, at different stages of sintering cycle, was studied using scanning electron microscope and EDS analysis. A comparative study was done between prealloyed- and premixed-based composites on the basis of densification, microstructure, hardness, transverse rupture strength and electrical conductivity as a function of TiB2 content. Results indicated that premixed-based composites have better mechanical properties than prealloyed-based composites.

Similar content being viewed by others

References

G.B. Schaffer, T.B. Sercombe, and R.N. Lumley, Liquid Phase Sintering of Aluminium Alloys, Mater. Chem. Phys., 2001, 67, p 85–91

R.N. Lumley, T.B. Sercombe, and G.M. Schaffer, Surface Oxide and the Role of Magnesium During the Sintering of Aluminum, Metall. Mater. Trans. A, 1999, 30, p 457–463

G.B. Schaffer, B.J. Hall, S.J. Bonner, S.H. Huo, and T.B. Sercombe, The Effect of the Atmosphere and the Role of Pore Filling on the Sintering of Aluminium, Acta Mater., 2006, 54, p 131–138

R.M. German, A Quantitative Theory for Supersolidus Liquid Phase Sintering, Powder Metall., 1991, 34, p 101–107

M. Youseffi and N. Showaiter, PM Processing of Elemental and Prealloyed 6061 Aluminium Alloy with and Without Common Lubricants and Sintering Aids, Powder Metall., 2006, 49, p 240–252

A. Ziani and S. Pelletier, Supersolidus Liquid-Phase Sintering Behavior of Degassed 6061 Al Powder, Int. J. Powder Metall., 1999, 35, p 49–58

E.M. Daver, W.J. Ullrich, and K. Balubhai Patel, Aluminium P/M parts-materials, production and properties, Key Engineering Materials, Vol. 30, P. Ramakrishnan, Ed., Trans Tech Publications, 1991, pp. 401–428

H. Asgharzadeh and A. Simchi, Supersolidus Liquid Phase Sintering of Al6061/SiC Metal Matrix Composites, Powder Metall., 2009, 52, p 28–35

N. Kumar, G. Gautam, R.K. Gautam, A. Mohan, and S. Mohan, Synthesis and Characterization of TiB2 Reinforced Aluminium Matrix Composites: A Review, J. Inst. Eng. Ser. D, 2016, 97(2), p 233-253

J.M. Torralba, C.E. Da Costa, and F. Velasco, P/M Aluminum Matrix Composites: An Overview, J. Mater. Process. Technol., 2003, 133, p 203–206

C. Padmavathi and A. Upadhyaya, Densification, Microstructure and Properties of Supersolidus Liquid Phase Sintered 6711Al-SiC Metal Matrix Composites, Sci. Sinter., 2010, 42, p 363–382

Y. Xian, X. Pang, S. He, W. Wang, X. Wang, and P. Zhang, Microstructure and Mechanical Properties of Al6061-31vol.% B4C Composites Prepared by Hot Isostatic Pressing, J. Mater. Eng. Perform., 2015, 24, p 4044–4053

S.C. Tjong and K.F. Tam, Mechanical and Thermal Expansion Behavior of Hipped Aluminum-TiB2 Composites, Mater. Chem. Phys., 2006, 97, p 91–97

S. Suresh and N.S.V. Moorthi, Process Development in Stir Casting and Investigation on Microstructures and Wear Behavior of TiB2 on Al6061 MMC, Procedia Eng., 2013, 64, p 1183–1190

R.M. German, Powder metallurgy science, Met. Powder Ind. Fed. 105 Coll. Rd. E, Princeton, NJ 08540, USA (1984)

E.O. Olakanmi, R.F. Cochrane, and K.W. Dalgarno, A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties, Prog. Mater. Sci., 2015, 74, p 401–477

G. O’donnell and L. Looney, Production of Aluminium Matrix Composite Components Using Conventional PM Technology, Mater. Sci. Eng. A, 2001, 303, p 292–301

V.V. Dabhade, T.R.R. Mohan, and P. Ramakrishnan, Sintering Behavior of Titanium-Titanium Nitride Nanocomposite Powders, J. Alloys Compd., 2008, 453, p 215–221

J.M. Martin and F. Castro, Liquid Phase Sintering of P/M Aluminium Alloys: Effect of Processing Conditions, J. Mater. Process. Technol., 2003, 143, p 814–821

Y. Xue, R. Shen, S. Ni, D. Xiao, and M. Song, Effects of Sintering Atmosphere on the Mechanical Properties of Al-Fe Particle-Reinforced Al-Based Composites, J. Mater. Eng. Perform., 2015, 24, p 1890–1896

N. Showaiter and M. Youseffi, Compaction, Sintering and Mechanical Properties of Elemental 6061 Al Powder With and Without Sintering Aids, Mater. Des., 2008, 29, p 752–762

A.P. Savitskii and L.S. Martsunova, Effect of Solid-State Solubility on the Volume Changes Experienced by Aluminum During Liquid-Phase Sintering, Powder Metall. Met. Ceram., 1977, 16, p 333–337

C. Padmavathi, A. Upadhyaya, and D. Agrawal, Effect of Microwave and Conventional Heating on Sintering Behavior and Properties of Al-Mg-Si-Cu Alloy, Mater. Chem. Phys., 2011, 130, p 449–457

T. Schubert, T. Pieczonka, S. Baunack, and B. Kieback, The Influence of the Atmosphere and Impurities on the Sintering Behaviour of Aluminium, Euro PM2005, Sintering, 2005, 1, p 3–8

G.B. Schaffer, J.-Y. Yao, S.J. Bonner, E. Crossin, S.J. Pas, and A.J. Hill, The Effect of Tin and Nitrogen on Liquid Phase Sintering of Al-Cu-Mg-Si Alloys, Acta Mater., 2008, 56, p 2615–2624

M. Paidpilli, K. Verma, R. Pandey, and A. Upadhyaya, Effect of Lead Addition and Milling on Densification and Mechanical Properties of 6061 Aluminium Alloys, Trans. Indian Inst. Met., 2016, doi:10.1007/s12666-016-1024-3

R.L. Coble, D. Kolar, S. Pejovnik, and M.M. Ristic, Sintering-Theory and Practice, Mater. Sci. Monogr., 1982, 14, p 145

R.M. German, Sintering Theory and Practice, Wiley-VCH, Weinheim, 1996, ISBN 0-471-05786-X

C. Padmavathi and A. Upadhyaya, Sintering Behaviour and Mechanical Properties of Al-Cu-Mg-Si-Sn Aluminum Alloy, Trans. Indian Inst. Met., 2011, 64, p 345–357

L. Tian, I. Anderson, T. Riedemann, and A. Russell, Modeling the Electrical Resistivity of Deformation Processed Metal-Metal Composites, Acta Mater., 2014, 77, p 151–161

D. Kwon, T.D. Nguyen, K.X. Huynh, P. Choi, M. Chang, Y. Yum, J. Kim, and Y. Kwon, Mechanical, Electrical and Wear Properties of Cu-TiB2 Nanocomposites Fabricated by MA-SHS and SPS, J. Ceram. Process. Res., 2006, 7, p 275

J.P. Tu, N.Y. Wang, Y.Z. Yang, W.X. Qi, F. Liu, X.B. Zhang, H.M. Lu, and M.S. Liu, Preparation and Properties of TiB 2 Nanoparticle Reinforced Copper Matrix Composites by In Situ Processing, Mater. Lett., 2002, 52, p 448–452

I.M. Daniel, O. Ishai, I.M. Daniel, and I. Daniel, Engineering Mechanics of Composite Materials, Oxford University Press, New York, 1994

H. Arik, Effect of Mechanical Alloying Process on Mechanical Properties of α-Si 3N 4 Reinforced Aluminum-Based Composite Materials, Mater. Des., 2008, 29, p 1856–1861

C.P. Samal, J.S. Parihar, and D. Chaira, The Effect of Milling and Sintering Techniques on Mechanical Properties of Cu-Graphite Metal Matrix Composite Prepared by Powder Metallurgy Route, J. Alloys Compd., 2013, 569, p 95–101

C. Padmavathi, A. Upadhyaya, and D. Agrawal, Effect of Sintering Temperature and Heating Mode on Consolidation of Al-7Zn-2· 5 Mg-1Cu Aluminum Alloy, Bull. Mater. Sci., 2012, 35, p 823–832

G.T. Campbell, R. Raman, and R. Fields, Optimum press and sinter processing for Aluminum/SiC composite, in Proceedings of the First International Conference on Powder Metallurgy, Aluminum & Light Alloys for Automotive Applications (MPIF, Princeton, 1998), pp. 35–42

E.A. Diler and R. Ipek, An Experimental and Statistical Study of Interaction Effects of Matrix Particle Size, Reinforcement Particle Size and Volume Fraction on the Flexural Strength of Al-SiC p Composites by P/M Using Central Composite Design, Mater. Sci. Eng. A, 2012, 548, p 43–55

Acknowledgments

The authors wish to acknowledge Dr. O.P. Modi, Head, Materials Characterization division (CSIR-AMPRI Bhopal) for his support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paidpilli, M., Gupta, G.K. & Upadhyaya, A. Sintering Response of Aluminum 6061-TiB2 Composite: Effect of Prealloyed and Premixed Matrix. J. of Materi Eng and Perform 26, 4470–4480 (2017). https://doi.org/10.1007/s11665-017-2883-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2883-4