Abstract

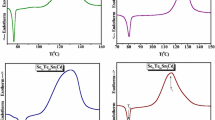

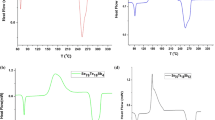

Three-component 40TeO2-(60-x)V2O5-xSb2O3 glasses with 0 ≤ x ≤ 10 (in mol.%) were obtained by the rapid melt-quenching method. These glasses were studied with respect to some mechanical properties with the goal of obtaining information about their structure. The Vickers hardness test was employed to obtain Vickers micro-hardness (H V) at two different loads, which was within the range of 13.187–17.557 GPa for a typical 0.1 HV (0.9807 N) load. In addition, theoretical micro-hardness (H) was investigated and compared with experimental H V, showing the elevating trend with increase of Sb2O3 content, as for H V. Furthermore, differential scanning calorimetry (DSC) was employed within the range of 150–500°C at heating rates of φ = 3 K/min, 6 K/min, 9 K/min, 10 K/min, and 13 K/min. In this work, thermal stability (T s = T cr − T x) and glass forming tendency (K gl) were measured and reported for these glasses to determine the relationship between the chemical composition and the thermal stability, in order to interpret the structure of glass. Generally, from the ascertained outputs [analysis of mechanical data, titration study, the values of reduced fraction of vanadium ions (C V) and oxygen molar volume (\( V_{\text{O}}^{*} \))], it was found that the micro-hardness had an increasing trend with increasing the Sb2O3 content. Among the studied glasses, the sample with x = 8 had a higher average micro-hardness value, the highest average thermal stability and glass forming tendency with respect to the other samples, which makes it a useful material (owning very good resistance against thermal attacks) for device manufacturing.

Similar content being viewed by others

References

R. El-Mallawany, Phys. Stat. Sol. (a) 177, 439 (2000).

A. Abdel-Kadar, R. El-Mallawany, and M.M. Elkholy, Appl. Phys. 73, 71 (1993).

R. El-Mallawani, A. Abousehly, and E. Yousef, J. Mater. Sci. Lett. 19, 409 (2000).

A. El-Adawy and R. El-Mallawani, J. Mater. Sci. Lett. 15, 2065 (1996).

D. Souri, J. Non-Cryst. Solids 356, 2181 (2010).

D. Souri and K. Shomalian, J. Non-Cryst. Solids 355, 1597 (2009).

S.A. Salehizadeh and D. Souri, J. Phys. Chem. Solids 72, 1381 (2011).

D. Souri, M. Mohammadi, and H. Zaliani, Electron. Mater. Lett. 10, 1103 (2014).

D. Souri, P. Azizpour, and H. Zaliani, J. Electron. Mater. 43, 3672 (2014).

R. El-Mallawany, J. Mater. Res. 7, 224 (1992).

R. El-Mallawany, M. Sidkey, A. Khafagy, and H. Afifi, Mater. Chem. Phys. 37, 295 (1994).

R. El-Mallawany and A.Abd. El-Moneim, Phys. Stat. Sol. (a) 166, 829 (1998).

H.M.M. Moawad, H. Jain, R. El-Mallawany, T. Ramadan, and M. El-Sharbiny, J. Am. Ceram. Soc. 85, 2655 (2002).

R. El-Mallawany, J. Mater. Res. 18, 402 (2003).

R. El-Mallawany, A. Abdel-Kader, M. El-Hawary, and N. El-Khoshkhany, J. Mater. Sci. 45, 871 (2010).

E.F. Lambson, G.A. Saunders, B. Bridge, and R.A. Mallawany, J. Non-Cryst. Solids 69, 117 (1984).

V. Rajendran, N. Palanivelu, B.K. Chaudhuri, and K. Goswami, J. Non-Cryst. Solids 320, 195 (2003).

Y. Dimitriev, V. Dimitriev, and M. Arunaudov, J. Mater. Sci. 18, 1353 (1983).

N. Palanivelu and V. Rajendran, Phys. Stat. Sol. (a) 203, 2347 (2006).

D. Souri, J. Mater. Sci. 46, 6998 (2011).

D. Souri and M. Elahi, Czech. J. Phys. 56, 419 (2006).

R. Muncaster and S. Parke, J. Non-Cryst. Solids 24, 399 (1977).

S. Jayaseelan, P. Muralidharan, M. Venkateswarlu, and N. Satyanarayana, Mater. Sci. Eng. B 118, 136 (2005).

G. Turky and M. Dawy, Mater. Chem. Phys. 77, 48 (2002).

S.R. Elliott, Physics of Amorphous Materials, 2nd ed. (Essex: Longman Scientific & Technical, 1990).

G.W. Scherer, Relaxation in Glasses and Composites (NewYork: Wiley, 1986).

I. Avramov, G. Guinev, and A.C.M. Rodrigues, J. Non-Cryst. Solids 271, 12 (2000).

A. Inoue, T. Zhang, and T. Masumoto, J. Non-Cryst. Solids 156–158, 473 (1993).

A. Hruby, Czech J. Phys. 22, 1187 (1972).

M.A. Paykani, M.N. Ahmadabadi, and A. Seiffodini, Intermetallics 46, 118 (2014).

D. Souri, J. Mater. Sci. 47, 625 (2012).

D. Souri, Eur. Phys. J. B 84, 47 (2011).

D. Souri, Measurement 44, 2049 (2011).

K. Yukimitu, R.C. Oliveira, E.B. Araujo, J.C.S. Moraes, and L.H. Avnci, Thermochim. Acta 426, 157 (2005).

D. Souri, Phys. B 456, 185 (2015).

H. Mori, H. Matsuno, and H. Sakata, J. Non-Cryst. Solids 276, 78 (2000).

H. Sakata, M. Amano, and T. Yag, J. Non-Cryst. Solids 194, 198 (1996).

H.H. Qiu, M. Kundo, and H. Sakata, Mater. Chem. Phys. 51, 233 (1997).

V. Keryvin, Acta Mater. 55, 2565 (2007).

G.S. Yu, J.G. Lin, W. Li, and S.F. Li, J. Alloys Compd. 482, 366 (2009).

C. Tang, Y. Li, and K. Zeng, Mat. Sci. Eng A 384, 215 (2004).

M.A. Sidkey, A.Abd. El-Moneim, and L.Abd. El-Latif, Mater. Chem. Phys. 61, 103 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Souri, D., Torkashvand, Z. Thermomechanical Properties of Sb2O3-TeO2-V2O5 Glassy Systems: Thermal Stability, Glass Forming Tendency and Vickers Hardness. J. Electron. Mater. 46, 2158–2163 (2017). https://doi.org/10.1007/s11664-016-5151-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5151-8