Abstract

In situ synthesis of carbon nanotubes (CNTs) on Ti powder decorated with Ni catalyst enabled us to obtain a high-quality CNTs/Ti composite powder via fluidized bed chemical vapor deposition (FBCVD) process. The composite powder was characterized by a combination of high structural integrity and uniform dispersion of CNTs, which is not obtained by traditional ball-milling route. These advantages enabled the retention of CNTs in the near-fully dense titanium matrix composite (TMC), together with the uniform dispersion of TiC particles. The CNTs and TiC particles coordinated with each other and contributed to a synergistic effect involving load transfer from the matrix to CNTs and dispersion strengthening of TiC particles. The nanotube–particle-reinforced TMC exhibited superior mechanical properties in comparison to single-phase-reinforced TMCs. The catalytic behavior of Ni, controllable synthesis of CNTs, the retention behavior of CNTs, and the formation mechanism of TiC particles during the sintering process are discussed in detail.

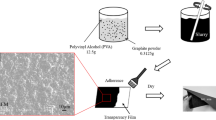

Graphic Abstract

Similar content being viewed by others

References

M.D. Hayatb, H. Singh, Z. He, and P. Cao: Compos. A Appl. Sci. Manuf., 2019, vol. 121, pp. 418–38.

H. Singh, M. Hayat, Z. He, V.K. Peterson, R. Das, and P. Cao: Compos. A Appl. Sci. Manuf., 2019, vol. 124, pp. 105501.

X.J. Zhang, F. Song, Z.P. Wei, W.C. Yang, and Z.K. Dai: Mater. Sci. Eng. A, 2017, vol. 705, pp. 153–9.

L.J. Huang, L. Geng, and H.X. Peng: Prog. Mater. Sci., 2015, vol. 71, pp. 93–168.

N. Shamsaei, A. Yadollahi, L. Bian, and S.M. Thompson: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2859–62.

L.J. Huang, L. Geng, H.Y. Xu, and H.X. Peng: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2859–62.

C. Cai, B. Song, C.L. Qiu, L.F. Li, P.J. Xue, Q.S. Wei, J.X. Zhou, H. Nan, H.X. Chen, and Y.S. Shi: J. Alloy. Compd., 2017, vol. 710, pp. 364–74.

Shirvanimoghaddam K, Hamim SU, Akbari MK, Fakhrhoseini SM, Khayyam H, Pakseresht AH, Ghasali E, Zabet M, Munir KS, Jia S, Davim JP, Naebe M (2017) Composites A 92:70–96

A. Azarniya, S. Sovizi, H.R.M. Hosseini, T. Varol, A. Kawasaki, and S. Ramakrishn: Prog. Mater. Sci., 2017, vol. 90, pp. 276–324.

B. Chen, S.F. Li, H. Imai, L. Jia, J. Umeda, M. Takahashi, and K. Kondoh: Compos. Sci. Technol., 2015, vol. 113, pp. 1–8.

J. Xiang, Y.F. Han, J.X. Li, P.K. Qiu, X.L. Sun, and W.J. Lu: J. Alloy. Compd., 2017, vol. 723, pp. 57–66.

L. Jia, X. Li, K. Kondoh, B. Chen, S.F. Li, J. Umeda, and Z.L. Lu: Mater. Charact., 2019, vol. 151, pp. 6–14.

Y. Jiao, L.J. Huang, and L. Geng: J. Alloy. Compd., 2018, vol. 767, pp. 1169–215.

S.F. Li, K. Kondoh, H. Imai, B. Chen, L. Jia, J. Umeda, and Y. Fu: Mater. Des., 2016, vol. 95, pp. 127–32.

F.C. Ma, T.R. Wang, P. Liu, W. Li, X.K. Liu, X.H. Chen, D. Pan, and W.J. Lu: Mater. Sci. Eng. A, 2016, vol. 654, pp. 352–8.

M.Y. Koo, J.S. Park, M.K. Park, K.T. Kim, and S.H. Hong: Scr. Mater., 2012, vol. 66, pp. 487–90.

F.C. Wang, Z.H. Zhang, Y.J. Sun, Y. Liu, Z.Y. Hu, H. Wang, A.V. Korznikov, E. Korznikova, and Z.F. Liu: Carbon, 2015, vol. 95, pp. 396–407.

K. Kondoh, T. Threrujirapapong, J. Umeda, and B. Fugetsu: Compos. Sci. Technol., 2012, vol. 72, pp. 1291–7.

S.F. Li, B. Sun, H. Imai, and K. Kondoh: Carbon, 2013, vol. 61, pp. 216–28.

P.M. Ajayan: Chem. Rev., 1999, vol. 99, pp. 1787–800.

K.S. Munir and C. Wen: Crit. Rev. Solid State Mater. Sci., 2016, vol. 41, pp. 347–66.

K.S. Munir, Y.C. Li, M. Qian, and C. Wen: Carbon, 2016, vol. 99, pp. 384–97.

V.S.A. Challa and R.D.K. Misra: Mater. Technol., 2017, vol. 32, pp. 109–15.

R.D.K. Misra, D. Depan, V.S.A. Challa, and J.S. Shah: Phys. Chem. Chem. Phys., 2014, vol. 16, pp. 19122–9.

R.D.K. Misra, D. Depan, V.S.A. Challa, and J.S. Shah: Phys. Chem. Chem. Phys., 2013, vol. 15, pp. 12988–97.

D. Depan and R.D.K. Misra: Nanoscale, 2012, vol. 4, pp. 6325–35.

R.D.K. Misra and P. Chaudhari: J. Biomed. Mater. Res. A, 2013, vol. 101A, pp. 1059–68.

R.D.K. Misra and P. Chaudhari: J. Biomed. Mater. Res. A, 2013, vol. 101, pp. 528–536.

Q. Yuan, Q. Bao, and R.D.K. Misra: Mater. Technol., 2012, vol. 27, pp.289–94.

R.D.K. Misra, D. Depan, and H. Narsale: Chem. Phys., 2012, vol. 213, pp. 1321–1329.

Z. Jia, F. Feng, Q. Yuan, and R.D.K. Misra: Mater. Sci. Eng. B, 2012, vol. 177, pp. 666–72.

C. Lei, G.Y. Zhang, Q.S. Zhu, and Z.H. Xie: Powder Technol., 2016, vol. 296, pp. 79–86.

S.F. Li, C. Tan, Y. Liu, P.P. Lv, Q.S. Zhu, Y. Shi, and Y.F. Yang: Materialia, 2018, vol. 2, pp. 68–72.

L. Zhang, F.X. Xin, Z. Du, M.Q. Xiang, Y.F. Yang, Q.S. Zhu, and Y. Shi: J. Am. Ceram. Soc., 2019, vol. 102, pp. 1599–607.

L. Zhang, F.X. Xin, S.F. Li, Y.F. Yang, Q.S. Zhu, and G. Wang: J. Am. Ceram. Soc., 2019, vol. 102, pp. 4492–501.

S.M. George: Chem. Rev., 2010, vol. 110, pp. 111–31.

Y. Yan, J. Miao, Z. Yang, F.X. Xiao, H.B. Yang, B. Liu, and Y.H. Yang: Chem. Soc. Rev., 2015, vol. 44, pp. 3295–346.

K.S. Munir, D.T. Oldfield, and C. Wen: Adv. Eng. Mater., 2016, vol. 18, pp. 294–303.

K.S. Munir, Y. Zheng, D. Zhang, J. Lin, Y. Li, and C. Wen: Mater. Sci. Eng. A, 2017, vol. 696, pp. 10–25.

K. Vasanthakumar, N.S. Karthiselva, N.M. Chawake, and S.R. Bakshi: J. Alloy. Compd., 2017, vol. 709, pp. 829–41.

A.O. Adegbenjoa, P.A. Olubambia, J.H. Potgieter, M.B. Shongwe, and M. Ramakokovhu: Mater. Des., 2017, vol. 128, pp. 119–29.

K.S. Munir, Y.F. Zheng, D.L. Zhang, J.X. Lin, Y.C. Li, and C. Wen: Mater. Sci. Eng. A, 2017, vol. 688, pp. 505–23.

F. Xue, J.H. Sui, F. Yan, and C. Wei: Mater. Sci. Eng. A, 2010, vol. 527, pp. 1586–9.

F.M. Zhang and T.F. Liu, Compos. Part B Eng., 2019, vol. 165, pp. 143–54.

Acknowledgments

The research study was supported by the DNL Cooperation Fund, CAS (No. DNL180304), the National Natural Science Foundation of China (Nos. 51801201 and 51874271), the Scientific Instrument Developing Project of the Chinese Academy of Sciences (No. YJKYYQ20190011), and the Key Research Program of Frontier Sciences, Chinese Academy of Sciences (Grant No. QYZDB-SSW-JSC045). The authors are grateful to Professor R. D. K. Misra for having agreed to collaborate in this study based on his prior experience with CNT-based composite systems.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 23, 2020.

Rights and permissions

About this article

Cite this article

Li, S.F., Cui, J.Y., Yang, L.F. et al. In Situ Growth of Carbon Nanotubes on Ti Powder for Strengthening of Ti Matrix Composite via Nanotube–Particle Dual Morphology. Metall Mater Trans A 51, 5932–5944 (2020). https://doi.org/10.1007/s11661-020-05988-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05988-7