Abstract

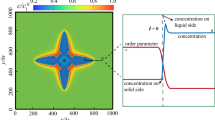

Simulation of the solid–liquid–gas interaction during solidification is challenging due to the presence of complex phase interfaces, bubble deformation, and high liquid/gas density ratio. In this work, a hybrid phase-field lattice-Boltzmann (PFLB) approach, together with a parallel and adaptive-mesh-refinement (Para-AMR) algorithm, is developed to model interactions between the gas bubble and solid growth front during solidification. The solid growth and bubble evolution are solved by the phase-field method. Both melt flow and bubble movement are determined by a kinetic-based lattice-Boltzmann model. Bubble dynamics during alloy solidification is modeled and compared with experiments, and a good agreement is achieved for various solid/liquid interfaces including planar, cellular, and dendritic interfaces. Results show that the effect of the bubble on solid array is dependent on the solid/liquid interface morphology, bubble size, and relative position between the bubble center and dendritic tip. Two interaction mechanisms, including engulfment and entrapment, are compared, and the difference is caused mainly by the redistribution of solute. The interaction mechanism between the rising multibubbles with large deformation and the dendritic array is also discussed.

Similar content being viewed by others

References

J.A. Dantzig and M. Rappaz: Solidification, EPFL Press, Lausanne, 2009.

P.D. Lee and J.D. Hunt: Acta Mater., 1997, vol. 45, pp. 4155–69.

H. Liao, L. Zhao, Y. Wu, R. Fan, Q. Wang, and Y. Pan: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 2587–90.

L. Arnberg and R.H. Mathiesen: Jom-Us, 2007, vol. 59, pp. 20–26.

M. Felberbaum and M. Rappaz: Acta Mater., 2011, vol. 59, pp. 6849–60.

L. Zhao, H. Liao, Y. Pan, L. Wang, and Q. Wang: Scripta Mater., 2011, vol. 65, pp. 795–98.

S. Morankar, M. Mandal, N. Kourra, M.A. Williams, R. Mitra, and P. Srirangam: Jom-Us, 2019, vol. 71, pp. 4050–58.

V. Khalajzadeh, K.D. Carlson, D.G. Backman, and C. Beckermann: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1797–1816.

P.D. Lee, A. Chirazi, and D. See: J. Light Met., 2001, vol. 1, pp. 15–30.

C. Pequet, M. Gremaud, and M. Rappaz: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2095–2106.

K.D. Carlson, Z. Lin, and C. Beckermann: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 541–55.

Q. Zhang, T. Wang, Z. Yao, and M. Zhu: Materialia, 2018, vol. 4, pp. 211–20.

H. Meidani and A. Jacot: Acta Mater., 2011, vol. 59, pp. 3032–40.

W.J. Boettinger, J.A. Warren, C. Beckermann, and A. Karma: Ann. Rev. Mater. Res., 2002, vol. 32, pp. 163–94.

M. Felberbaum and A. Jacot: in Modeling of Casting, Welding, and Advanced Solidification Processes—XII, S.L. Cockcroft and D.M. Maijer, eds., TMS, Warrendale, PA, 2009, pp. 369–76.

A. Carré, B. Böettger, and M. Apel: Int. J. Mater. Res., 2010, vol. 101, pp. 510–14.

J. Eiken, B. Boettger, and I. Steinbach: Phys. Rev. E, 2006, vol. 73, p. 066122.

L. Du, L. Wang, B. Zheng, and H. Du: Comp. Mater. Sci., 2016, vol. 114, pp. 94–98.

J.C. Ramirez, C. Beckermann, A. Karma, and H.J. Diepers: Phys. Rev. E, 2004, vol. 69, p. 051607.

A. Zhang, J. Du, Z. Guo, Q. Wang, and S. Xiong: Phys. Rev. E, 2019, vol. 100, p. 023305.

T. Krüger, H. Kusumaatmaja, A. Kuzmin, O. Shardt, G. Silva, and E.M. Viggen: The Lattice Boltzmann Method Principles and Practice, Springer, Cham, Switzerland, 2017.

A. Zhang, S. Meng, Z. Guo, J. Du, Q. Wang, and S. Xiong: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1514–26.

T. Takaki, R. Rojas, S. Sakane, M. Ohno, Y. Shibuta, T. Shimokawabe, and T. Aoki: J. Cryst. Growth, 2017, vol. 474, pp. 146–53.

D. Medvedev and K. Kassner: Phys. Rev. E, 2005, vol. 72, p. 056703.

A. Zhang, J. Du, Z. Guo, Q. Wang, and S. Xiong: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 517–30.

A. Zhang, J. Du, Z. Guo, and S. Xiong: Phys. Rev. E, 2018, vol. 98, p. 043301.

A. Zhang, J. Du, Z. Guo, Q. Wang, and S. Xiong: Scripta Mater., 2019, vol. 165, pp. 64–67.

X. Zhang, J. Kang, Z. Guo, S. Xiong, and Q. Han: Comput. Phys. Commun., 2018, vol. 223, pp. 18–27.

A. Zhang, J. Du, Z. Guo, Q. Wang, and S. Xiong: Philos. Mag., 2019, vol. 99, pp. 2920–40.

A. Zhang, J. Du, Z. Guo, Q. Wang, and S. Xiong: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3603–15.

A. Zhang, Z. Guo, Q. Wang, and S. Xiong: Phys. Fluids, 2019, vol. 31, p. 063106.

P.L. Bhatnagar, E.P. Gross, and M. Krook: Phys. Rev., 1954, vol. 94, pp. 511–25.

Z. Guo, C. Zheng, and B. Shi: Phys. Rev. E, 2002, vol. 65, p. 046308.

C. Beckermann, H.J. Diepers, I. Steinbach, A. Karma, and X. Tong: J. Comput. Phys., 1999, vol. 154, pp. 468–96.

A. Fakhari, M. Geier, and T. Lee: J. Comput. Phys., 2016, vol. 315, pp. 434–57.

J. Du, A. Zhang, Z. Guo, M. Yang, M. Li, and S. Xiong: Phys. Rev. Mater., 2018, vol. 2, p. 083402.

J. Du, A. Zhang, Z. Guo, M. Yang, M. Li, F. Liu, and S. Xiong: Acta Mater., 2018, vol. 161, pp. 35–46.

A. Zhang, Z. Guo, and S.M. Xiong: Phys. Rev. E, 2018, vol. 97, p. 053302.

M. Berger and I. Rigoutsos: IEEE Trans. Syst. Man. Cybern., 1991, vol. 21, pp. 1278–86.

J. Du, A. Zhang, Z. Guo, M. Yang, M. Li, and S. Xiong: ACS Omega, 2017, vol. 2, pp. 8803–09.

A. Karma and W. Rappel: Phys. Rev. E, 1998, vol. 57, pp. 4323–49.

S. Hou, Q. Zou, S. Chen, G. Doolen, and A. Cogley: J. Comput. Phys., 1994, vol. 118, pp. 329–47.

H.Z. Yuan, C. Shu, Y. Wang, and S. Shu: Phys. Fluids, 2018, vol. 30, p. 040908.

R. Krishna, M.I. Urseanu, J.M. van Baten, and J. Ellenberger: Int. Commun. Heat Mass Transfer, 1999, vol. 26, pp. 781–90.

D. Bhaga and M.E. Weber: J. Fluid Mech., 1981, vol. 105, pp. 61–85.

M. Alizadeh, S.M. Seyyedi, M.T. Rahni, and D.D. Ganji: J. Mol. Liq., 2017, vol. 236, pp. 151–61.

A. Zhang, J. Du, S. Meng, F. Liu, Z. Guo, Q. Wang, and S. Xiong: Comp. Mater. Sci., 2019, vol. 171, p. 109274.

H. Xing, J.Y. Wang, C.L. Chen, K.X. Jin, and Z.F. Shen: Scripta Mater., 2010, vol. 63, pp. 1228–31.

H. Xing, J.Y. Wang, C.L. Chen, Z.F. Shen, and C.W. Zhao: J. Cryst. Growth, 2012, vol. 338, pp. 256–61.

W.W. Mullins and R.F. Sekerka: J. Appl. Phys., 1964, vol. 35, pp. 444–51.

S.H. Han and R. Trivedi: Acta Metall. Mater., 1994, vol. 42, pp. 25–41.

Acknowledgments

This work is financially supported by the Joint Funds of the National Natural Science Foundation of China (Grant No. U1537202) and the Tsinghua-General Motors International Collaboration Project (Grant No. 20153000354). The authors also thank the National Laboratory for Information Science and Technology, Tsinghua University, for access to its supercomputing facilities.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 13, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, A., Du, J., Zhang, X. et al. Phase-Field Modeling of Microstructure Evolution in the Presence of Bubble During Solidification. Metall Mater Trans A 51, 1023–1037 (2020). https://doi.org/10.1007/s11661-019-05593-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05593-3