Abstract

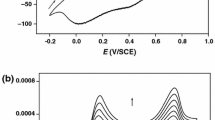

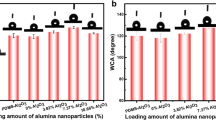

ZnO nanoparticles were synthesized by the traditional sol–gel method followed by a thermal treatment at different temperatures (673 K, 873 K, or 1073 K) and addition of different amounts (2, 4, or 6 wt pct) into a commercial waterborne polyurethane (WBPU) matrix in order to produce hybrid coatings for corrosion inhibition of AISI 1018 carbon steel (CS). The different hybrid coatings were deposited by the spraying method after being magnetically stirred for 60 minutes. The effects of the thermal treatments on the structural, optical, and morphological properties of ZnO particles were analyzed by X-ray diffraction, ultraviolet visible spectroscopy (UV–vis), and scanning electron microscopy. Changes in the electrochemical performances of waterborne polyurethane-coated carbon steel attributable to the incorporation of ZnO powders were investigated by the open-circuit potential, electrochemical impedance spectroscopy, and potentiodynamic polarization techniques in chloride medium. Also, structural, chemical, and mechanical properties were characterized in the hybrid coatings to evaluate the interaction type, UV degradation, adhesion, and hardness. The results revealed that the crystallite size of ZnO particles was within the interval ranging from 33.10 ± 0.02 to 72.00 ± 0.05 nm, which increased with the increasing temperature of thermal treatment. The treatment temperature modified the morphology of the ZnO particles, where a rod-type morphology was observed at 673 K, whereas agglomerated hexagonal facets were obtained at 1073 K. ZnO powders can reinforce the optical properties of WBPU coatings, which could delay the structural damage of the polymer, particularly in the UV region, and transparency can be modulated depending on the crystallite size, the amount of added ZnO, and the thermal treatment. The 6 wt pct (673 K) loading of ZnO particles during the WBPU polymerization improved the mechanical properties from 79.2 ± 4 to 165.5 ± 0.1 MPa. The electrochemical performance suggests that ZnO reinforced the barrier properties of WBPU, but at the same time supplied active protection by precipitating zinc hydroxide species in the cathodic sites. Kinetic parameters and impedance analysis showed that hybrid coatings containing 6 wt pct of the treated ZnO particles (673 K) displayed the best protection efficiency of AISI 1018 CS.

Similar content being viewed by others

References

K.L. Noble: Prog. Org. Coat., 1997, vol. 32, pp. 131-136.

D.K. Chattopadhyay, K.V.S.N. Raju: Prog. Polym. Sci., 2007, vol. 32, pp. 352-418.

D. K. Chattopadhyay, D.C. Webster: Prog. Polym. Sci., 2009, vol. 34, pp. 1068-1133.

X. Ye, Z. Wang, L. Ma, Q. Wang, A. Chu: Surf. Coat. Technol., 2019, vol. 358, pp. 497-504.

M.F. Montemor: Surf. Coat. Technol., 2014, vol. 258, pp. 17-37.

A. Ehsani, M.G. Mahjani, M. Hosseini, R. Safari, R. Moshrefi, H. M. Shiri: J. Colloid Interface Sci., 490:444–451;2017

Z. Lei, Q. Zhang, X. Zhu, D. Ma, F. Ma, Z. Song, Y.Q. Fu: Appl. Surf. Sci., 2018, vol. 431, pp. 170-176.

H. Huang, D. Zhang, S. Fang, J. Zhu, X. Peng: Prog. Org. Coat., 2019, vol. 126, pp. 44-52.

J. Zhao, T. Zhou, J. Zhang, H. Chen, C. Yuan, W. Zhang, A. Zhang: Ind. Eng. Chem. Res., 2014, vol. 53, pp. 19257-19264.

M.M. Rahman, H. Kim: J. Appl. Polym. Sci., 2006, vol. 102, pp. 5684-5691.

G.N. Chen, K.N. Chen: J. Appl. Polym. Sci., 1997, vol. 63, pp. 1609-1623.

M.M. Rahman, M.H. Zahir, M.B. Haq, D.A.A. Shehri, A.M. Kumar: Coat., 2018, vol. 8, 34 pp. 1-12.

G. Christopher, M.A. Kulandainathan, G. Harichandran: J. Coat. Technol. Res., 2015, vol. 12, pp. 657-667.

J. Li, Z. Zhao, Y. Zhang, M. Li, Z. Luo, Luo: J. Sol-Gel Sci. Tech., 2017, 82:299-307.

M. Hasani, M. Mahdavian, H. Yari, B. Ramezanzadeh: Prog. Org. Coat., 2018, vol. 116, pp. 90-101.

A.M. El Saeed, M.A. El-Fattah, A.M. Azzam: Dyes. Pigm., 2015, vol. 121, pp. 282-289.

Y. Qing, C. Yang, C. Hu, Y. Zheng, C. Liu: Appl. Surf. Sci., 2015, vol. 326, pp. 48-54.

M.M. Alves, D.V. Cunha, C.F. Santos, N.P. Mira, M.F. Montemor: Ceram. Int., 2018, vol. 44, pp. 4467-4472.

J.S. Park, I. Mahmud, H.J. Shin, M.K. Park, A. Ranjkesh, D.K. Lee, H.R. Kim: Appl. Suf. Sci., 2016, vol. 362, pp. 132-139.

M. Cao, F. Wang, J. Zhu, X. Zhang, Y. Qin, L. Wang: Mater. Lett., 2017, vol. 192, pp. 1-4.

Y.M. Im, T.H. Oh, J.A. Nathanael, S.S. Jang: Mater. Lett., 2015, vol. 147, pp. 20-24.

G.J. Owens, R.K. Singh, F. Foroutan, M. Alqaysi, C.M. Han, C. Mahapatra, H.W. Kim, J.C. Knowles: Prog. Mater. Sci., 2016, vol. 77, pp. 1-79.

H. Schmidt: J. Non-Cryst. Solids, 1988, vol. 100, pp. 51-64.

L. Chagnon, G. Arnold, S. Giljean, M. Brogly: Prog. Org. Coat., 2013, vol. 76, pp. 1337-1345.

C.A. Schuh: Mater. Today, 2006, vol. 9, pp. 32-40.

ASTM: D4541-17 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers, 2017.

M. Pudukudy, Z. Yaakob: Appl. Surf. Sci., 2014, vol. 292, pp. 520-530.

P. Chand, A. Gaur, A. Kumar: J. Alloys Compd., 2012, vol. 539, pp. 174-178.

K. Omri, I. Najeh, R. Dhahri, J. El Ghoul, L. El Mir: Microelectron. Eng., 2014, vol. 128, pp. 53-58.

K. Harun, N. Mansor, Z.A. Ahmad, A.A. Mohamad: Procedia Chem., 2016, vol. 19, pp. 125-132.

K. Ocakoglu, S.A. Mansour, S. Yildirimcan, A.A. Al-Ghamdi, F. El-Tantawy, F. Yakuphanoglu: Spectrochim. Acta A, 2015, vol. 148, pp. 362-368.

Y. Zhou, L. Xu, Z. Wu, P. Li, J. He: Optik, 2017, vol. 130, pp. 673-680.

P. Kubelka, F. Munk: Z. Tech. Phys, 1931, vol. 12, pp. 593-601.

A.E. Morales, E.S. Mora, U. Pal: Rev. Mex. Fis. E, 2007, vol. 53, pp. 18-22.

M.M. Ba-Abbad, A.A.H. Kadhum, A.B. Mohamad, M.S. Takriff, K. Sopian: J. Alloys Compd., 2013, vol. 550, pp. 63-70.

S.J. Pearton, D.P. Norton, K. Ip, Y.W. Heo, T. Steiner: Prog. Mater. Sci., 2005, vol. 50, pp. 293-340.

H. Nakatani, H. Ooike, T. Kishida, S. Motokucho: Prog. Org. Coat., 2016, vol. 97, pp. 269-276.

X. Gu, G. Chen, M. Zhao, S.S. Watson, T. Nguyen, J.W. Chin, J.W. Martin: J. Coat. Technol. Res., 2012, vol. 9, pp. 251-267.

M. Rashvand, Z. Ranjbar, S. Rastegar: Prog. Org. Coat., 2011, vol. 71, pp. 362-368.

A.L. Tolstov, O.V. Zinchenko, V.F. Matyushov: Theor. Exp. Chem., 2015, vol. 51, pp. 333-338.

M.A. Reyes-Acosta, A.M. Torres-Huerta, M.A. Dominguez-Crespo, A.I. Flores-Vela, H.J. Dorantes-Rosales, E. Ramírez-Meneses: J. Alloys Compd., 2015, vol. 643, pp. S150-S158.

B. Soltani, M. Asghari: Membranes, 2017, vol. 7, 43, pp. 1-16.

L. Podgorski, M. de Meijer, J.D. Lanvin: Coat., 2017, vol. 7, 163 pp. 1-11.

L. Mohammed, M.N.M. Ansari, G. Pua, M. Jawaid, M. S. Islam: Int. J. Polym. Sci., 2015, vol. 2015 pp. 1-15.

S. Goel, G. Cross, A. Stukowski, E. Gamsjäger, B. Beake, A. Agrawal: Comput. Mater. Sci., 2018, vol. 152, pp. 196-210.

D. Kim, K. Jeon, Y. Lee, J. Seo, K. Seo, H. Han, S. Khan: Prog. Org. Coat., 2012, vol. 74, pp. 435-442.

B. Poon, D. Rittel, G. Ravichandran: Int. J. Solids Struct., 2008, vol. 45, pp. 6399-6415.

D. Del Angel-López, M.A. Domínguez-Crespo, A.M. Torres-Huerta, A. Flores-Vela, J. Andraca-Adame, H. Dorantes-Rosales: J. Mater.Sci., 2013, vol. 48, pp. 1067-1084.

F. Mansfeld, M.W. Kendig, S. Tsai: Corros., 1982, vol. 38, pp. 478-485.

M. Kendig, J. Scully: Corros., 1990, vol. 46, pp. 22-29.

Y. Xua, M. Liu: Geothermics, 2017, vol. 70, pp. 339–350.

J. Bico, U. Thiele, D. Quéré: Colloids Surf. A, 2002, vol. 206, pp. 41-46.

X. Zhang, R. Ma, A. Du, Q.Liu, Y. Fan, X. Zhao, J. Wu, X. Cao. Applied Surface Science 484 (2019) 814–824.

G. Christopher, M. A. Kulandainathan, G. Harichandran. Progr. Org. Coat. 99:91–102;2016.

X. J. Raj. Journal of Materials Engineering and Performance JMEPEG (2017) 26:3245–3253.

B.N. Zand, M. Mahdavian: Surf. Coat. Technol., 2009, vol. 203, pp. 1677–1681.

B.N. Zand, M. Mahdavian: Electrochim. Acta, 2007, vol. 52, pp. 6438-6442.

P. E. Plueddemann: Silane Coupling Agents, 2nd ed., Springer, New York, NY, 1991, pp. 115–152.

T.H. Chiang, T.-E. Hsieh: Int. J. Adhes. Adhes., 2006, vol. 26, pp. 520-531.

Y. González-García, S. González, R.M. Souto: Corros. Sci., 2007, vol. 49, pp. 3514-3526.

S.K. Dhoke, R. Bhandari, A.S. Khanna: Prog. Org. Coat., 2009, vol. 64, pp. 39-46.

K. Chrissafis, G. Antoniadis, K.M. Paraskevopoulos, A. Vassiliou, D.N. Bikiaris: Compos. Sci. Technol. 2007, vol. 67, pp. 2165-74.

Acknowledgments

Patricia Salazar Bravo is grateful for the received postgraduate grant through SENER-CONACyT. The authors are also grateful for the financial support provided by the CONACYT Research Fellowship-IPN-CICATA Altamira agreement, 2014-1905 and CONACyT CB2015-252181 projects; Instituto Politécnico Nacional through the SIP2019-6650, SIP2019-6670 and SIP2019-6718 projects; as well as SNI-CONACyT.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 1, 2019.

Rights and permissions

About this article

Cite this article

Salazar-Bravo, P., Del Angel-López, D., Torres-Huerta, A.M. et al. Investigation of ZnO/Waterborne Polyurethane Hybrid Coatings for Corrosion Protection of AISI 1018 Carbon Steel Substrates. Metall Mater Trans A 50, 4798–4813 (2019). https://doi.org/10.1007/s11661-019-05375-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05375-x