Abstract

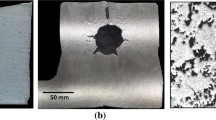

The formation of shrinkage porosity in an A356 aluminum alloy wedge casting is investigated using real-time video radiography. An image processing technique is developed to quantify the amount of porosity observed in the video. The transient temperature field is obtained using casting simulation. The results show that initially, sinks develop in the low solid fraction regions on the surface of the wedge. Once the surface becomes sufficiently solid to be rigid, the subsequent solidification shrinkage is accommodated by internal porosity. The internal porosity is found to nucleate and grow in the central part of the wedge where the solid fraction is the lowest. A computational model is developed to predict the formation of the surface sinks and the internal porosity. The model is validated using the experimental measurements and a parametric study is performed to investigate the sensitivity of the predictions to changes in the model parameters.

Similar content being viewed by others

References

M. J. Couper, A.E. Neeson, and J.R. Griffiths: Fatigue Fract. Eng. Mater. Struct., 1990, vol. 13, pp. 213-27.

Q.G. Wang, D. Apelian, and D.A. Lados: J. Light Met., 2001, vol. 1, pp. 73–84.

R.A. Hardin and C. Beckermann: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5316–32.

T.S. Piwonka and M.C. Flemings: Trans. AIME, 1966, vol. 236, pp. 1157–65.

K. Kubo and R.D. Pehlke: Metall. Trans. B, 1985, vol. 16, pp. 359–66.

C. Pequet, M. Gremaud, and M. Rappaz: Metall. Mater. Trans., 2002, vol. 33A, pp. 2095–16.

K.D. Carlson, Z. Lin, R.A. Hardin, and C. Beckermann: 56th Steel Founders Society of America Technical and Operating Conference, Paper No. 4.4, Steel Founders’ Society of America, Chicago, IL, 2002.

K.D. Carlson, Z. Lin, and C. Beckermann: Metall. Mater. Trans. B, 2007, vol. 38 (4), pp. 541–55.

K.D. Carlson and C. Beckermann: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 163–75.

A. Reis, Y. Houbaert, Z. Xu, R. Van Tol, A.D. Santos, J.F. Duarte, and A.B. Magalhaes, J. Mater. Process. Tech., 2008, vol. 202, pp. 428-434.

A. Reis, Z. Xu, R.V. Tol, and R. Neto, J. Manuf. Process., 2012, vol. 14, pp. 1-7.

Y. Awano, and K. Morimoto. Int. J. Cast Met. Res., 2004, vol. 17, pp. 107-114.

P.D. Lee and J.D. Hunt: Acta Mater., 1997, vol. 45, pp. 4155-4169.

R.C. Atwood, S. Sridhar, W. Zhang, and P.D. Lee: Acta Mater., 2000, vol. 48, pp. 405-417.

L. Arnberg and R. Mathiesen: JOM, 2007, vol. 59, pp. 20–26.

JMatPro, Sente Software Ltd, Surrey Technology Center, Surrey GU2 7YG, United Kingdom.

MAGMAsoft, MAGMA Gmbh, Aachen

D. Emadi and L.V. Whiting: AFS Trans., 2002, 200, 33.

K.D. Carlson and C. Beckermann: Int. J. Cast Met. Res., 2012, vol. 25, pp. 75–92.

S. Thompson, S. L. Cockcroft, and M. A. Wells: Mater. Sci. Tech., 2004, vol. 20, pp. 194-200.

L. Arnberg, G. Chai, and L. Backerud: Mater. Sci. Engrg. A, 1993, vol. 173, pp. 101-03.

Acknowledgments

The authors wish to thank Anil Sachdev, Gene Tuohy, Mike Walker, and Jason Traub for their support of the foundry real-time X-ray room at GM R&D and the work on this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 24, 2018.

Rights and permissions

About this article

Cite this article

Khalajzadeh, V., Goettsch, D.D. & Beckermann, C. Real-time X-ray Radiography and Computational Modeling of Shrinkage Porosity Formation in Aluminum Alloy Castings. Metall Mater Trans A 50, 757–771 (2019). https://doi.org/10.1007/s11661-018-5018-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5018-0