Abstract

The formation, growth, and size distribution of precipitates greatly affects the microstructure and properties of microalloyed steels. Computational particle-size-grouping (PSG) kinetic models based on population balances are developed to simulate precipitate particle growth resulting from collision and diffusion mechanisms. First, the generalized PSG method for collision is explained clearly and verified. Then, a new PSG method is proposed to model diffusion-controlled precipitate nucleation, growth, and coarsening with complete mass conservation and no fitting parameters. Compared with the original population-balance models, this PSG method saves significant computation and preserves enough accuracy to model a realistic range of particle sizes. Finally, the new PSG method is combined with an equilibrium phase fraction model for plain carbon steels and is applied to simulate the precipitated fraction of aluminum nitride and the size distribution of niobium carbide during isothermal aging processes. Good matches are found with experimental measurements, suggesting that the new PSG method offers a promising framework for the future development of realistic models of precipitation.

Similar content being viewed by others

Abbreviations

- a :

-

empirical coefficient for turbulence collision

- \( c_{\text{M}} ,\,c_{\text{P}} \) :

-

lattice parameter of the matrix and precipitate phase (m)

- \( c_{\text{M}}^{e} ,\,c_{\text{P}}^{e} \) :

-

nearest-neighbor distance across the interface for matrix and precipitate phase (m)

- \( f \) :

-

transformed fraction in phase transformation

- \( f_{\text{P}} \) :

-

particle (or mass) fraction precipitated (relative to 100pct at zero dissolved)

- \( i_{\text{M}} \) :

-

number of pseudomolecules for the largest agglomerated particle in simulation

- \( m_{j} \) :

-

number of pseudomolecules contained in PSG volume V j

- \( m_{j - 1,j} \) :

-

number of pseudomolecules contained in PSG threshold volume V j–1,j

- \( n \) :

-

Avrami exponent in KJMA model

- \( n_{0} \) :

-

initial total number density of single pseudomolecules for collision problem (# m–3)

- \( n_{{1,{\text{eq}}}} \) :

-

equilibrium concentration of dissolved single pseudomolecules for diffusion problem (# m–3)

- \( n_{1i} \) :

-

equilibrium concentration of single pseudomolecules at surface of size i particles (# m–3)

- \( n_{i} \) :

-

number density of size i particles (# m–3)

- \( n_{\text{p}} \) :

-

total number density of precipitate particles (# m–3)

- \( n_{s} \) :

-

released number density of single pseudomolecules for diffusion problem (# m–3)

- \( n_{j}^{C} \) :

-

number density of particles at the center of size group j (# m–3)

- \( n_{j}^{L} \) :

-

number density of border particles, representing the smallest particles in size group j (# m–3)

- \( n_{j}^{R} \) :

-

number density of border particles, representing the largest particles in size group j (# m–3)

- \( r_{i} \,,\,r_{j} \) :

-

characteristic radius of size i particles, or size group j particles (m)

- \( r_{j - 1,j} \) :

-

threshold radius to separate size group j − 1 and size group j particles in PSG method (m)

- \( r_{c} \) :

-

the critical radius for nucleation (m)

- \( \bar{r}_{\text{P}} \) :

-

average precipitate particle size (m)

- \( t \) :

-

time (s)

- Δt :

-

time step size in numerical computation (s)

- \( w_{\text{P}}^{e} \) :

-

equilibrium mass concentration of precipitate phase (wt pct)

- \( A_{i} ,\,A_{j} \) :

-

the surface area of size i particles, or size group j particles (m2)

- \( A_{\text{M}} \) :

-

atomic mass unit of element M (g mol–1)

- \( D \) :

-

diffusion coefficient of the precipitation in the parent phase (m2 s–1)

- \( D_{f} \) :

-

fractal dimension for precipitate morphology

- \( G_{M} \) :

-

number of size groups for the largest agglomerated particle in PSG method

- \( G_{T} \) :

-

truncating size group in PSG method to match experimental resolution

- \( K \) :

-

rate function for nucleation and growth in KJMA model

- \( M_{0} \) :

-

total mass concentration of alloying element M in the steel composition (wt pct)

- \( [M] \) :

-

equilibrium mass concentration of alloying element M (wtpct)

- \( N_{j} \) :

-

total number density of size group j particles in PSG method (# m−3)

- \( N_{\text{A}} \) :

-

Avogadro number (6.022 × 1023 # mol–1)

- \( N_{M} \) :

-

total number density of pseudomolecules (# m–3)

- \( N_{s} \) :

-

number of atoms per unit area across the interface (# m–2)

- \( N_{\text{T}} \) :

-

total number density of all particles (# m–3)

- \( {\text{R}}_{\text{g}} \) :

-

gas constant (8.314 J K–1 mol–1)

- \( R_{\text{V}} \) :

-

particle volume ratio between two neighboring particle size groups

- \( T \) :

-

absolute temperature (K)

- \( V_{i} ,\,V_{j} \) :

-

characteristic volume of size i particles or size group j particles (m3)

- \( V_{j - 1,j} \) :

-

threshold volume to separate size group j – 1 and size group j particles in PSG method (m3)

- \( V_{\text{P}} \) :

-

molar volume of precipitated phase (m3 mol–1)

- \( X_{\text{M}} ,\;X_{\text{P}} \) :

-

molar concentration of precipitate-forming element in matrix and precipitate phases

- \( Z_{s} \) :

-

number of bonds per atom across the interface

- \( Z_{l} \) :

-

coordinate number of nearest neighbors within the crystal lattice

- \( \alpha_{i} \) :

-

dissociation rate of size i particles (m2 s–1)

- \( \beta_{i} \) :

-

diffusion growth rate of size i particles (m3 #–1 s–1)

- \( \delta \) :

-

relative lattice misfit across the interface between pairs of precipitate and matrix atoms

- \( \delta_{i,k} \) :

-

Kronecker’s delta function (δ i,k = 1 for i = k, δ i,k = 0 for i ≠ k)

- \( \varepsilon \) :

-

turbulent energy dissipation rate (m2 s–3)

- \( \mu_{\text{M}} ,\,\mu_{\text{P}} ,\,\mu_{\text{I}} \) :

-

shear modulus of the matrix, precipitate phase, and interface (Pa)

- \( \nu_{\text{M}} ,\,\nu_{\text{P}} \) :

-

Poisson’s ratio of the matrix and precipitate phases

- \( \rho_{\text{steel}} ,\,\rho_{\text{p}} \) :

-

density of steel matrix and precipitate phase (kg m–3)

- \( \sigma \) :

-

interfacial energy between precipitated particle/matrix (J m–2)

- \( \sigma_{c} \) :

-

chemical interfacial energy between precipitated particle/matrix (J m–2)

- \( \sigma_{\text{st}} \) :

-

structural interfacial energy between precipitated particle/matrix (J m–2)

- \( \upsilon \) :

-

kinematic viscosity (m2 s–1)

- \( \varphi_{P} \) :

-

volume fraction of precipitate phase

- \( \Upphi_{i,k} \) :

-

collision frequency between size i and size k particles (m3 #−1 s–1)

- Π:

-

supersaturation

- \( \Updelta E_{0} \) :

-

heat of solution of precipitate in a dilute solution of matrix (J mol–1)

- \( \Updelta G_{V} \) :

-

change of Gibbs free energy per unit volume during precipitation (J m–3)

- \( \Updelta H \) :

-

heat of formation of precipitate (J mol–1)

- \( * \) :

-

dimensionless value

- \( - \) :

-

average value

- L, R, C:

-

left, right border-size, and center-size particles in each size group

- \( {\text{ceil}}(x) \) :

-

the smallest integer which is not less than real number \( x \)

- \( {\text{floor}}(x) \) :

-

the largest integer which is not larger than real number \( x \)

References

C. Zener: Trans. Am. Inst. Miner. Metall. Soc., 1948, vol. 175, pp. 15-51.

M. Hillert: Acta Metall., 1965, vol. 13, pp. 227-38.

T. Gladman: Proc. Roy. Soc. London Ser. A, 1966, vol. 294, pp. 298-309.

P.A. Manohar, M. Ferry, and T. Chandra: ISIJ Int., 1998, vol. 38, pp. 913-24.

N. Yoshinaga, K. Ushioda, S. Akamatsu, and O. Akisue: ISIJ Int., 1994, vol. 34, pp. 24-32.

E.E. Kashif, K. Asakura, T. Koseki, and K. Shibata: ISIJ Int., 2004, vol. 44, pp. 1568-75.

S.C. Park, I.H. Jung, K.S. OH, and H.G. Lee: ISIJ Int., 2004, vol. 44, pp. 1016-23.

Y. Li, J.A. Wilson, D.N. Crowther, P.S. Mitchell, A.J. Craven, and T.N. Baker: ISIJ Int., 2004, vol. 44, pp. 1093-1102.

R.L. Klueh, K. Shiba, and M.A. Sokolov: J. Nucl. Mater., 2008, vol. 377, pp. 427-37.

J.Y. Choi, B.S. Seong, S.C. Baik, and H.C. Lee: ISIJ Int., 2002, vol. 42, pp. 889-93.

B.J. Lee: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2423-39.

R.C. Hudd, A. Jones, and M.N. Kale: J. Iron Steel Inst., 1971, vol. 209, pp. 121-25.

T. Gladman: The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, UK, 1997, pp. 82-130.

W.J. Liu and J.J. Jonas: Metall. Trans. A, 1989, vol. 20A, pp. 1361-74.

N. Gao and T.N. Baker: ISIJ Int., 1997, vol. 37, pp. 596-604.

J.Y. Park, J.K. Park, and W.Y. Choo: ISIJ Int., 2000, vol. 40, pp. 1253-59.

K. Xu, B.G. Thomas, and R. O’Malley: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 524-39.

A.N. Kolmogorov: Izv. Akad. Nauk SSSR, Ser. Fiz., 1937, vol. 1, pp. 335-38.

W.A. Johnson and R.F. Mehl: Trans. AIME, 1939, vol. 135, pp. 416-42.

M. Avrami: J. Chem. Phys., 1939, vol. 7, pp. 1103-12; 1940, vol. 8, pp. 212-24; 1941, vol. 9, pp. 177-83.

J.W. Christian: The Theory of Transformation in Metals and Alloys. Part I, Pergamon Press, Oxford, UK, 1975.

N.Y. Zolotorevsky, V.P. Pletenev, and Y.F. Titovets: Model. Simul. Mater. Sci. Eng., 1998, vol. 6, pp. 383-91.

H.C. Kang, S.H. Lee, D.H. Shin, K.J. Lee, S.J. Kim, and K.S. Lee: Mater. Sci. Forum, 2004, vols. 449-452, pp. 49-52.

M. Smoluchowski: Z. Phys. Chem., 1917, vol. 92, pp. 127-55.

P.G. Saffman and J.S. Turner: J. Fluid Mech., 1956, vol. 1, pp. 16-30.

U. Lindborg and K. Torssell: Trans. TMS-AIME, 1968, vol. 242, pp. 94-102.

S.K. Friedlander and C.S. Wang: J. Colloid Interface Sci., 1966, vol. 22, pp. 126-32.

V.G. Levich: Physicochemical Hydrodynamics, Prentice-Hall, Inc., Englewood Cliffs, NJ, 1962, pp. 211.

D. Turnbull and J.C. Fisher: J. Chem. Phys., 1949, vol. 17, pp. 71-73.

W.J. Liu and J.J. Jonas: Metall. Trans. A, 1989, vol. 20A, pp. 689-97.

W.J. Liu and J.J. Jonas: Metall. Trans. A, 1988, vol. 19A, pp. 1403-13.

W. Ostwald: Lehrbruck der allgemeinen Chemie, 1896, vol. 2, Leipzig, Germany.

I.M. Lifshitz and V.V. Slyozov: J. Phys. Chem. Solids, 1961, vol. 19, pp. 35-50.

C. Wagner: Zeitschrift Zeitschr. Elektrochemie, 1961, vol. 65, pp. 581-91.

C. Zener: J. Appl. Phys., 1949, vol. 20, pp. 950-53.

K.C. Russell: Adv. Colloid Interface Sci., 1980, vol. 13, pp. 205-318.

H.I. Aaronson, L. Laird, and K.R. Kinsman: Phase Transformations, Ed. H.I. Aaronson, ASM, Materials Park, OH, 1970, pp. 313-96.

M. Kahlweit: Adv. Colloid Interface Sci., 1975, vol. 5, pp. 1-35.

J. Miyake and M.E. Fine: Scripta Metall. Mater., 1991, vol. 25, pp. 191-94.

R. Kampmann, H. Eckerlebe, and R. Wagner: Mater. Res. Soc. Symp. Proc., 1987, vol. 57, pp. 526-42.

L.M. Cheng, E.B. Hawbolt, and T.R. Meadowcroft: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1907-16.

F. Perrard, A. Deschamps, and P. Maugis: Acta Mater., 2007, vol. 55, pp. 1255-66.

J. Stávek and M. Šípek: Cryst. Res. Technol., 1995, vol. 30, pp. 1033-49.

S. Müller, C. Wolverton, L.W. Wang, and A. Zunger: Europhys. Lett., 2001, vol. 55, pp. 33-39.

E. Clouet, M. Nastar, and C. Sigli: Phys. Rev. B, 2004, vol. 69, p. 064109.

C. Hin, B.D. Wirth, and J.B. Neaton: Phys. Rev. B, 2009, vol. 80, p. 134118.

R. Mukherjee, T.A. Abinandanan, and M.P. Gururajan: Acta Mater., 2009, vol. 57, pp. 3947-54.

R. Mukherjee, T.A. Abinandanan, and M.P. Gururajan: Scripta Mater., 2010, vol. 62, pp. 85-88.

Y. Tsukada, A. Shiraki, Y. Murata, S. Takaya, T. Koyama, and M. Morinaga: J. Nucl. Mater., 2010, vol. 401, pp. 154-58.

J. Svoboda, F.D. Fischer, P. Fratzl, and E. Kozeschnik: Mater. Sci. Eng. A, 2004, vol. 385, pp. 166-74.

E. Hozeschnik, J. Svoboda, P. Fratzl, and F.D. Fischer: Mater. Sci. Eng. A, 2004, vol. 385, pp. 157-65.

E. Kozeschnik, J. Svoboda, R. Radis, and F.D. Fischer: Model. Simul. Mater. Sci. Eng., 2010, vol. 18, p. 015011.

E. Clouet, A. Barby, L. Laé, and G. Martin: Acta Mater., 2005, vol. 52, pp. 2313-25.

J. Lepinoux: Acta Mater., 2009, vol. 57, pp. 1086-94.

J. Lepinoux: Philos. Mag., 2010, vol. 90, pp. 3261-80.

L. Kampmann and M. Kahlweit: Ber. Bunsenges. Phys. Chem., 1970, vol. 74, pp. 456-62.

J. Zhang and H. Lee: ISIJ Int., 2004, vol. 44, pp. 1629-38.

Y.J. Kwon, J. Zhang, and H.G. Lee: ISIJ Int., 2008, vol. 48, pp. 891-900.

N. Zhang and Z.C. Zheng: J. Phys. D: Appl. Phys., 2007, vol. 40, pp. 2603-12.

Y. Miki, B.G. Thomas, A. Denissov, and Y. Shimada: Ironmaker Steelmaker, 1997, vol. 24, pp. 31-38.

Y. Miki and B.G. Thomas: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 639-54.

L. Zhang, S. Tanighchi, and K. Cai: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 253-66.

D. Sheng, M. Söder, P. Jönsson, and L. Jonsson: Scand. J. Metall., 2002, vol. 31, pp. 134-47.

M. Hallberg, P.G. Jönsson, T.L.I. Jonsson, and R. Eriksson: Scand. J. Metall., 2005, vol. 34, pp. 41-56.

T. Nakaoka, S. Taniguchi, K. Matsumoto, and S.T. Johansen: ISIJ Int., 2001, vol. 41, pp. 1103-11.

L. Zhang and W. Pluschkell: Ironmaking Steelmaking, 2003, vol. 30, pp. 106-10.

F. Gelbard, Y. Tambour, and J.H. Seinfeld: J. Colloid Interface Sci., 1980, vol. 76, pp. 541-56.

J.J. Wu and R.C. Flagan: J. Colloid Interface Sci., 1988, vol. 123, pp. 339-52.

H. Tozawa, Y. Kato, K. Sorimachi, and T. Nakanishi: ISIJ Int., 1999, vol. 39, pp. 426-34.

K. Higashitani, Y. Yamauchi, Y. Matsuno, and G. Hosokawa: J. Chem. Eng. Jpn., 1983, vol. 116, pp. 299-304.

F. Vodopivec: J. Iron Steel Inst., 1973, vol. 211, pp. 664-65.

H.F. Beeghly: Ind. Eng. Chem., 1942, vol. 14, pp. 137-40.

T. Gladman: The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, UK, 1997, pp. 206-07.

H. Oikawa: Tetsu-to-Hagane, 1982, vol. 68, pp. 1489-97.

W.C. Leslie, R.L. Rickett, C.L. Dotson, and C.S. Walton: Trans. Am. Soc. Metall., 1954, vol. 46, pp. 1470-99.

F.G. Wilson and T. Gladman: Int. Mater. Rev., 1988, vol. 33, pp. 221-86.

R. Radis and E. Kozeschnik: Mater. Sci. Forum, 2010, vols. 636–637, pp. 605–11.

R. Radis and E. Kozeschnik: Model. Simul. Mater. Sci. Eng., 2010, vol. 18, p. 055003.

F. Perrard, A. Deschamps, F. Bley, P. Donnadieu, and P. Maugis: J. Appl. Crystallogr., 2006, vol. 39, pp. 473-82.

J. Geise and C. Herzig: Z. Metallkd, 1985, vol. 76, pp. 622-26.

T. Gladman: The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, UK, 1997, pp. 82-130.

E.K. Strorms and N.H. Krikorian: J. Phys. Chem., 1960, vol. 64, pp. 1471-77.

S.M. He, N.H. Van Dijk, M. Paladugu, H. Schut, J. Kohlbrecher, F.D. Tichelaar, and S. Van Der Zwaag: Phys. Rev. B, 2010, vol. 82, p. 174111.

F.F. Abraham: Homogeneous Nucleation Theory. Academic Press, New York, NY, 1974.

B. Dutta and C.M. Sellars: Mater. Sci. Technol., 1987, vol. 3, pp. 197-206.

J.P. Michel and J.J. Jonas: Acta Metall., 1981, vol. 29, pp. 513-26.

A. LE Bon, J. Rofes-Vernis, and C. Rossard: Met. Sci., 1975, vol. 9, pp. 36-40.

A.R. Jones, P.R. Howell, and B. Ralph: J. Mater. Sci., 1976, vol. 11, pp. 1600-06.

D. Turnbull: Impurities and Imperfections, Seminar Proceedings, ASM, Cleveland, OH, 1955, pp. 121-44.

W.J. Liu and J.J. Jonas: Mater. Sci. Technol., 1989, vol. 5, pp. 8-12.

J.H. Van Der Merwe: J. Appl. Phys., 1963, vol. 34, pp. 117–22.

R.G. Baker and J. Nutting: Precipitation Process in Steels, Special Report No. 64, The Iron and Steel Institute, London, UK, 1959, pp. 1–22.

H. Shoji: Z. Kristallogr., 1931, vol. 77, pp. 381-410.

Z. Nishiyama: Science Report, Tohoku Imperial Univ., 1936, vol. 25, pp. 79.

W.G. Burgers: Physica, 1934, vol. 1, pp. 561-86.

N.W. Chase, Jr.: NIST-JANAF Thermochemical Tables, 4th ed., J. Phys. Chem. Ref. Data, 1998, pp. 1–1951.

L.E. Toth: Transaction Metal Carbides and Nitrides, Academic Press, New York, NY, 1971.

H.J. Frost and M.F. Ashby: Deformation-Mechanism Maps, Pergamon Press, Oxford, UK, 1982, pp. 20-70.

L.M. Cheng, E.B. Hawbolt, and T.R. Meadowcroft: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1907-16.

L.R. Zhao, K. Chen, Q. Yang, J.R. Rodgers, and S.H. Chiou: Surf. Coat. Technol., 2005, vol. 200, pp. 1595-99.

Acknowledgment

The authors thank the Continuous Casting Consortium at the University of Illinois at Urbana-Champaign and the National Science Foundation (Grant CMMI-0900138) for support of this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 10, 2010.

Appendix: Calculation of Interfacial Energy

Appendix: Calculation of Interfacial Energy

According to Turnbull[89] and Liu and Jonas,[90] the interfacial energy consists of two parts: a chemical part (σ c) and a structural part (σ st), so that

The chemical interfacial energy is estimated from the difference between the energies of bonds broken in the separation process and of bonds made in forming the interface, with only the nearest neighbors considered. As given by Russell[36]

where ΔE 0 is the heat of solution of precipitates in a dilute solution in the matrix, N s is the number of atoms per unit area across the interface, Z s is the number of bonds per atom across the interface, Z l is the coordinate number of nearest neighbors within the precipitate crystal lattice, and X P and X M are the molar concentrations of the precipitate-forming element in the precipitate (P) and matrix (M) phase, respectively. ΔE 0 is estimated to equal –ΔH, the heat of formation of the precipitate. X P = 0.5 and X P >> X M.

Van Der Merwe[91] presented a calculation of structural energy for a planar interface. When the two phases have the same structure and orientation but different lattice spacing, the mismatch may be accommodated by a planar array of edge dislocations. Including the strain energy in both crystals, σ st is given as

where \( c_{\text{M}}^{e} \) and \( c_{\text{P}}^{e} \) are the nearest-neighbor distance across the interface, which are estimated from the lattice parameters c M, c P, and interface orientations; \( \bar{c} \) is the spacing of a reference lattice across the matrix/precipitate interface; μ M, μ P, and μ I are shear modulii in the matrix (M), precipitate (P), and interface (I), respectively; ν M and ν P are Poisson’s ratios; and δ is the lattice misfit across the interface.

The crystallographic relationships between the AlN (hexagonal close packed [hcp]), NbC (face centered cubic [fcc]), and steel matrix austenite phase (fcc) or ferrite phase (base-centered cubic [bcc]) are chosen as \( (100)_{\text{NbC}} //(100)_{{\alpha{\text{-Fe}}}} \),[92]\( (0001)_{\text{AlN}} //(111)_{{\gamma{\text{-Fe}}}} \),[93,94] and \( (0001)_{\text{AlN}} //(110)_{{\alpha{\text{-Fe}}}} \).[95]

The physical properties used in the calculation are \( - \Updelta H_{\text{A1N}} ({\text{KJ/mol}}) = 341.32 - 4.98 \times 10^{ - 2} T - 1.12 \times 10^{ - 6} T^{2} - 2813/T \),[96] \( - \Updelta H_{\text{NbC}} ({\text{KJ/mol}}) = 157.76 - 4.54\,\, \times \,\,10^{ - 2} T - 3.84\,\, \times \,\,10^{ - 6} T^{2} \),[97] \( \mu_{{\gamma{\text{-Fe}}}} ({\text{GPa}}) = 81\left[ {1 - 0.91(T - 300)/1810} \right] \),[98] \( \nu_{{\gamma{\text{-Fe}}}} = 0.29 \),[99] \( c_{{\gamma{\text{-Fe}}}} (nm) = 0.357 \),[73] \( \mu_{{\alpha{\text{-Fe}}}} (GPa) = 69.2\left[ {1 - 1.31(T - 300)/1810} \right] \),[98] \( \nu_{{\alpha{\text{-Fe}}}} = 0.29 \),[99] \( c_{{\alpha{\text{-Fe}}}} ({\text{nm}}) = 0.286 \),[73] \( \mu_{\text{AlN}} ({\text{GPa}}) = 127 \),[100] \( \nu_{\text{AlN}} = 0.23 \),[100] \( a_{\text{AlN}} ({\text{nm}}) = 0.311 \), \( c_{\text{AlN}} ({\text{nm}}) = 0.497 \),[73] \( \mu_{\text{NbC}} ({\text{GPa}}) = 134\left[ {1 - 0.18(T - 300)/3613} \right] \),[98] \( \nu_{\text{NbC}} = 0.194 \),[98] \( c_{\text{NbC}} ({\text{nm}}) = 0.446 \).[73]

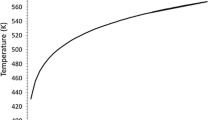

For γ-Fe (111) plane, \( Z_{\text{s}}^{{\gamma - {\text{Fe}}}} = 3 \) and \( N_{\text{s}}^{{\gamma - {\text{Fe}}}} = 4/(\sqrt 3 c_{{\gamma - {\text{Fe}}}}^{2} ) \). For α-Fe, (110) plane \( Z_{\text{s}}^{{\alpha{\text{-Fe}}}} = 4,\) \( N_{\text{s}}^{{\alpha{\text{-Fe}}}} = \sqrt 2 /c_{{\alpha{\text{-Fe}}}}^{2} \), (100) plane \( Z_{\text{s}}^{{\alpha{\text{-Fe}}}} = 4 \), and \( N_{\text{s}}^{{\alpha{\text{-Fe}}}} = 1/c_{{\alpha - {\text{Fe}}}}^{2} \). For both fcc and hcp precipitate structures, \( Z_{l} = 12 \). The calculated interfacial energy decreases slightly as temperature increases and also decreases for NbC (relative to AlN) because of lower heat of formation. The values used in the current simulations are

Rights and permissions

About this article

Cite this article

Xu, K., Thomas, B.G. Particle-Size-Grouping Model of Precipitation Kinetics in Microalloyed Steels. Metall Mater Trans A 43, 1079–1096 (2012). https://doi.org/10.1007/s11661-011-0938-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0938-y