Abstract

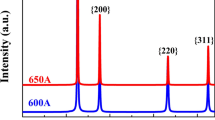

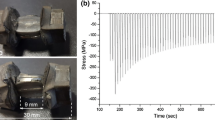

In order to examine the microstructural evolution during hot-compression deformation of the biomedical Co-29Cr-6Mo (weight percent) alloy without the addition of Ni, hot-compression tests have been conducted at deformation temperatures ranging from 1050 °C to 1200 °C at various strain rates of 10−3 to 10 s−1. The grain refinement due to dynamic recrystallization (DRX) was identified under all deformation conditions by means of field-emission scanning electron microscopy/electron backscattered diffraction (FESEM/EBSD) and transmission electron microscopy (TEM) observations. Although the DRX grain size (d) of the deformed specimens considerably decreased with an increasing Zener–Hollomon (Z) parameter at strain rates ranging from 10−3 to 0.1 s−1, a grain size coarser than that predicted from the d-Z relation was obtained at strain rates of 1.0 and 10 s−1. An ultrafine-grained microstructure with a grain size of approximately 0.6 μm was obtained under deformation at 1050 °C at 0.1 s−1, from an initial grain size of 40 μm. The grain refinement to a submicron scale of biomedical Co-Cr-Mo alloys has been achieved with hot deformation by ~60 pct due to DRX, in which the bulging mechanism is not operative. The ultrafine grains obtained due to DRX without bulging is closely related to the considerably low stacking-fault energy (SFE) of the Co-Cr-Mo alloy at deformation temperatures.

Similar content being viewed by others

Notes

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

Gatan is a trademark of Gatan, Inc., Warrendale, PA

References

A. Chiba, K. Kumagai, H. Takeda, and N. Nomura: Mater. Sci. Forum, 2005, vols. 475–479, pp. 2317–22.

R. Valiev: Nat. Mater., 2004, vol. 3, pp. 511–16.

Y. Fukuda, K. Oh-ishi, Z. Horita, and T.G. Langdon: Acta Mater., 2002, vol. 50, pp. 1359–68.

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, K. Tsuzaki, and Y. Watanabe: Acta Mater., 2008, vol. 56, pp. 821–34.

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong: Scripta Mater., 1998, vol. 39, pp. 1221–27.

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai: Acta Mater., 1999, vol. 47, pp. 579–83.

A. Belyakov, T. Sakai, H. Miura, R. Kaibyshev, and K. Tsuzaki: Acta Mater., 2002, vol. 50, pp. 1547–57.

J. Xing, X. Yang, H. Miura, and T. Sakai: Mater. Trans., 2008, vol. 49, pp. 69–75.

T. Sakai and J.J. Jonas: Acta Metall., 1984, vol. 32, pp. 189–209.

A. Belyakov, H. Miura, and T. Sakai: Mater. Sci. Eng., A, 1998, vol. A255, pp. 139–47.

A.M. Wusatowska-Sarnek, H. Miura, and T. Sakai: Mater. Sci. Eng., A, 2002, vol. A323, pp. 177–86.

C. Sommitsch and W. Mitter: Acta Mater., 2006, vol. 54, pp. 357–75.

N. Tsuji, Y. Matsubara, and Y. Saito: Scripta Mater., 1997, vol. 37, pp. 477–84.

H. Yagi, N. Tsuji, and Y. Saito: Tetsu-to-Hagané, 2000, vol. 86, pp. 349–56.

H. Monajati, M. Jahazi, S. Yue, and A.K. Taheri: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 895–905.

Y.P. Li, E. Onodera, H. Matsumoto, and A. Chiba: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 982–90.

J. Talonen and H. Hänninen: Acta Mater., 2007, vol. 55, pp. 6108–18.

G.B. Olson and M. Cohen: Metall. Trans. A, 1976, vol. 7A, pp. 1897–1904.

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng., A, 2004, vols. A387–A389, pp. 158–62.

Y.V.R.K. Prasad: JMEPEG, 2003, vol. 12, pp. 638–45.

S.H. Lee, T. Uchikanezaki, N. Nomura, M. Nakamura, and A. Chiba: Mater. Trans., JIM, 2007, vol. 48, pp. 1084–88.

A. Chiba, S.H. Lee, H. Matsumoto, and M. Nakamura: Mater. Sci. Eng., A, 2009, vols. 513–514, pp. 286–93.

Ika Kartika, H. Matsumoto, and A. Chiba: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 1457–68.

P. Huang and H.F. López: Mater. Lett., 1999, vol. 39, pp. 249–53.

T. Maki and I. Tamura: Tetsu-to-Hagané, 1984, vol. 15, pp. 2073–80.

C.M. Sellars and W.J. McG. Tegart: Mem. Sci. Rev. Met., 1966, vol. 63, pp. 731–45.

Nippon Kinzoku Gakkai: Kinzoku Data Book, 4th ed., Maruzen, Tokyo, 2004, p. 21.

L.X. Li, Y. Lou, L.B. Yang, D.S. Peng, and K.P. Rao: Mater. Des., 2002, vol. 23, pp. 451–57.

X. Fang, D. Yi, B. Wang, C. Wu, and H. Zhang: Rare Met., 2008, vol. 27, pp. 121–26.

I. Salbatori, T. Inoue, and K. Nagai: ISIJ Int., 2002, vol. 42, pp. 744–50.

A.P. Miodownik: CALPHAD, 1978, vol. 2, pp. 207–26.

T. Ericsson: Acta Metall., 1966, vol. 14, pp. 853–65.

T.S. Byun: Acta Mater., 2003, vol. 51, pp. 3063–71.

N. Tsuji, T. Shinmiya, Y. Saito, and M. Muraki: ISIJ Int., 1998, vol. 38, pp. 380–89.

N. Tsuji, Y. Matsubara, Y. Saito, and T. Maki: J. Jpn. Inst. Met., 1998, vol. 62, pp. 967–76.

X. Wang, E. Brünger, and G. Gottstein: Mater. Sci. Eng., A, 2000, vol. A290, pp. 180–85.

Acknowledgment

This research was supported by the Cooperation of Innovative Technology and Advanced Research in Evolutional Area under the Ministry of Education, Culture, Sports, Science and Technology (Tokyo, Japan).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 30, 2009.

Rights and permissions

About this article

Cite this article

Yamanaka, K., Mori, M., Kurosu, S. et al. Ultrafine Grain Refinement of Biomedical Co-29Cr-6Mo Alloy during Conventional Hot-Compression Deformation. Metall Mater Trans A 40, 1980–1994 (2009). https://doi.org/10.1007/s11661-009-9879-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9879-0