Abstract

Purpose

The aim of this paper is to evaluate assumptions and data used in calculations related to palm oil produced for biodiesel production relative to the European Renewable Energy Directive (EU-RED). The intent of this paper is not to review all assumptions and data, but rather to evaluate whether the methodology is applied in a consistent way and whether current default values address relevant management practices of palm oil production systems.

Methods

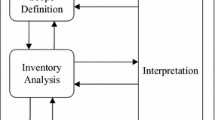

The GHG calculation method provided in Annex V of the EU-RED was used to calculate the GHG-emissions from palm oil production systems. Moreover, the internal nitrogen recycling on the plantation was calculated based on monitoring data in North Sumatra.

Results and discussion

A calculation methodology is detailed in Annex V of the EU-RED. Some important aspects necessary to calculate the GHG emission savings correctly are insufficiently considered, e.g.:

• “Nitrogen recycling” within the plantation due to fronds remaining on the plantation is ignored. The associated organic N-input to the plantation and the resulting nitrous oxide emissions is not considered within the calculations, despite crop residues being taken into account for annual crops in the BIOGRACE tool.

• The calculation of GHG-emissions from residue and waste water treatment is inappropriately implemented despite being a hot-spot for GHG emissions within the life cycle of palm oil and palm oil biodiesel. Additionally, no distinction is made between palm oil and palm kernel oil even though palm kernel oil is rarely used for biodiesel production.

• The allocation procedure does not address the most relevant oil mill management practices. Palm oil mills produce crude palm oil (CPO) in addition either nuts or palm kernels and nut shells. In the first case, the nuts would be treated as co-products and upstream emissions would be allocated based on the energy content; in the second case the kernels would be treated as co-products while the shelöls are considered as waste without upstream emissions. This has a significant impact on the resulst or GHG savings, respectively.

• It is not specified whether indirect GHG emissions from nitrogen oxide emission from the heat and power unit of palm oil mills should be taken into account.

Conclusions and recommendations

In conclusion, the existing calculation methodology described in Annex V of the EU-RED and default values are insufficient for calculating the real GHG emission savings from palm oil and palm oil biodiesel. The current default values do not reflect relevant management practices. Additionally, they protect poor management practices, such as the disposal of empty fruit bunches (EFB), and lead to an overestimation of GHG savings from palm oil biodiesel. A default value for EFB disposal must be introduced because resulting GHG emissions are substantial. Organic nitrogen from fronds must be taken into account when calculating real GHG savings from palm oil biodiesel. Further, more conservative data for FFB yield and fugitive emissions from wastewater treatment should be introduced in order to foster environmental friendly management options. Moreover, credits for bioenergy production from crop residues should be allowed in order to foster the mobilization of currently unused biomass.

Similar content being viewed by others

Notes

www.bigrace.net (accessed 06.03.2012, version 4b)

Other GHG calculators for palm oil such as the GHG calculator of the Roundtable of Sustainable Palm Oil (RSPO) or the GREET-tool are beyond the scope of this paper, because those tools do not apply the calculation methodology outlined in Annex V of the EU-RED.

IPCC Vol. 4 Equation 11.6, see Fracrenew(t)

Methane density ~0.72 kg m3

References

Aalders IH, Aitkenhead MJ (2006) Agricultural census data and land use modelling. Comp Environ Urban Syst 30(6):799–814. doi:10.1016/j.compenvurbsys.2005.06.003

Achten WMJ, Vandenbempt P, Almeida J, Mathijs E, Muys B (2010) Life cycle assessment of a palm oil system with simultaneous production of biodiesel and cooking oil in cameroon. Environ Sci Technol 44(12):4809–4815. doi:10.1021/es100067p

Adjei-Nsiah S, Sakyi-Dawson O, Kuyper TW (2012) Exploring opportunities for enhancing innovation in agriculture: the case of oil palm production in Ghana. J Agric Sci 4(10):212–223

Agyei-Dwarko D, G Okyere-Boateng (2010) Selection of New Standard Crosses for the Oil Palm (Elaeis Guineensis J.) Third Cycle of Selection. J Ghana Sci Assoc 12(1)

Arrieta FRP, Teixeira FN, Yáñez E, Lora E, Castillo E (2007) Cogeneration potential in the Columbian palm oil industry: Three case studies. Biomass Bioenergy 31(7):503–511

Banse M, van Meijl H, Tabeau A, Woltjer G, Hellmann F, Verburg PH (2011) Impact of EU biofuel policies on world agricultural production and land use. Biomass Bioenergy 35(6):2385–2390

Benoist A, Dron D, Zoughaib A (2012) Origins of the debate on the life-cycle greenhouse gas emissions and energy consumption of first-generation biofuels – A sensitivity analysis approach. Biomass Bioenergy 40:133–142. doi:10.1016/j.biombioe.2012.02.011

Brandão M, Milà i Canals L, Clift R (2011) Soil organic carbon changes in the cultivation of energy crops: Implications for GHG balances and soil quality for use in LCA. Biomass Bioenergy 35(6):2323–2336. doi:10.1016/j.biombioe.2009.10.019

Bringezu S (2009) Assessing Biofuels. ISBN: 978-92-807-3052-4

Bringezu S, O’Brien M, Schütz H (2012) Beyond biofuels: Assessing global land use for domestic consumption of biomass: A conceptual and empirical contribution to sustainable management of global resources. Land Use Policy 29(1):224–232. doi:10.1016/j.landusepol.2011.06.010

Buratti C, Fantozzi F (2010) Life cycle assessment of biomass production: Development of a methodology to improve the environmental indicators and testing with fiber sorghum energy crop. Biomass Bioenergy 34(10):1513–1522

Carter C, Finley W, Fry J, Jackson D, Willis L (2007) Palm oil markets and future supply. Eur J Lipid Sci Technol 109(4):307–314

Chavalparit O (2003) Industrial ecosystems in the crude palm oil industry in Thailand. In: Inrefagits Working Conference, p 1046

Chavalparit O, Rulkens WH, Mol APJ, Khaodhair S (2006) Options for environmental sustainability of the crude palm Oil industry in thailand through enhancement of industrial ecosystems. Environ Dev Sustain 8(2):271–287

Chen SS (2008) The LCA approach to illustrate palm Oil's sustainability advantage. In: International Palm Oil Sustainability Conference, Sabah

Choo Y, Muhamad H, Hashim Z, Subramaniam V, Puah C, Tan Y (2011) Determination of GHG contributions by subsystems in the oil palm supply chain using the LCA approach. Int J Life Cycle Assess 16(7):669–681. doi:10.1007/s11367-011-0303-9

Cocklin CR (1989) Methodological problems in evaluating sustainability. Environ Conserv 16(4):343–351. doi:10.1017/S0376892900009772

Corley RH, Tinker PB (2003) The palm oil, 4th edn. Blackwell, Oxford

Corley RH, Gray BS, Ng SK (1971) Productivity of the oil palm (Elaeis gueneeis Jacq.). Expl Agric 7:129–136

de Vries SC, van de Ven GWJ, van Ittersum MK, Giller KE (2010) Resource use efficiency and environmental performance of nine major biofuel crops, processed by firstgeneration conversion techniques. Biomass Bioenergy 34(5):588–601. doi:10.1016/j.biombioe.2010.01.001

Di Lucia L, Ahlgren S, Ericsson K (2012) The dilemma of indirect land-use changes in EU biofuel policy – An empirical study of policy-making in the context of scientific uncertainty. Environ Sci Policy 16:9–19. doi:10.1016/j.envsci.2011.11.004

Dumelin E, Rao V, Smith BG, Corley RH (2002) Sustainable Palm oil agriculture - The Unilever initiative. International Palm Oil Conference, Nusa Dua, pp 226–237

EC (2003) Directive 2003/30/EC of the European parlamen and of the council of 8 May 2003 on the promotion of the use of biofuels or other renewable fuels for transport

EC (2012) Proposal for a Directive of the European parliament and of the council amending Directive 98/70/EC relating to the quality of petrol and diesel fuels and amending Directive 2009/28/EC on the promotion of the use of energy from renewable sources

Edward C, Leonard EGP, Cahn A (1999) Proceedings of the world conference on palm and coconut oils for the 21st century. The American Oil Chemists Society, Denpasar

Edwards R (2007) Well-to-Wheels analysis of future automotive fuels and powertrains on the European context. EU JRC

EU (2009) Directive 2009/28/EC of the European parliament and of the council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC.

Flesch TK, Desjardins RL, Worth D (2011) Fugitive methane emissions from an agricultural biodigester. Biomass Bioenergy 35(9):3927–3935. doi:10.1016/j.biombioe.2011.06.009

FNR (2009) Biogas-Messprogramm II

Gawel E, Ludwig G (2011) The iLUC dilemma: How to deal with indirect land use changes when governing energy crops? Land Use Policy 28(4):846–856. doi:10.1016/j.landusepol.2011.03.003

Goh KJ (2005) Fertilizer recommendation system for oil palm: estimating the fertilizer rates. In: Chew PS, Tan YP (eds) MOSTA Best Practice Workshops - Agronomy and Crop Management, Malaysian Oil Scientists and Technologists Assosciation, pp 253–268

Hedal Kløverpris J, Baltzer K, Nielsen P (2010) Life cycle inventory modelling of land use induced by crop consumption. Int J Life Cycle Assess 15(1):90–103. doi:10.1007/s11367-009-0132-2

Henson IE (1999) Comparative ecophysiology of oil palm and tropical rain forest In: Oil palm and the environment. Malaysian Oil Palm Growers’ Council, Kuala Lumpur

Henson IR, Ruiz R, Romero HM (2011) The growth of the oil palm industry in Columbia. J Palm Oil Res 23:1121–1128

Idris MSH (2003) Fattening of beef cattle with oil palm by-products – Oil palm frond based diets. In: Forages and feed resources in commercial livestock production systems. 8th meeting of the regional working group on grazing and feed resources for Southeast Asia, Kuala Lumpur, pp 71–75

IPCC (2006a) IPCC Guidelines for National Greenhouse Gas Inventories (Agriculture)

IPCC (2006b) Waste (Vol.5, Chapter 4). Available at: http://www.ipccnggip.iges.or.jp/public/

Jungbluth N, Chudacoff M, Dauriat A, Dinkel F, Doka G, Emmenegger F, Gnansounou E, Kljun N, Schleiss K, Spielmann M, Stettler C, Sutter J (2007) Life cycle inventories of bioenergy. vol ecoinvent report No. 17. Swiss Centre for Life Cycle Inventories, Dübendorf

Kaewmai R, H-Kittikun A, Musikavong C (2012) Greenhouse gas emissions of palm oil mills in Thailand. Int J Greenh Gas Control 11:141–151. doi:10.1016/j.ijggc.2012.08.006

Kaewmai R, H-Kittikun A, Suksaroj C, Musikavong C (2013) Alternative Technologies for the Reduction of Greenhouse Gas Emissions from Palm Oil Mills in Thailand. Environ Sci Technol. doi:10.1021/es4020585

Kamahara H, Hasanudin U, Widiyanto A, Tachibana R, Atsuta Y, Goto N, Daimon H, Fujie K (2010) Improvement potential for net energy balance of biodiesel derived from palm oil: A case study from Indonesian practice. Biomass and Bioenergy. doi:10.1016/j.biombioe.2010.07.014

Khalid H, Zin ZZ, Anderson JM (2000) Decomposition processes and nutrient release patterns of oil palm residues. J Oil Palm Res 12(1):46–63

Kim S, Dale BE (2011) Indirect land use change for biofuels: testing predictions and improving analytical methodologies. Biomass Bioenergy 35(7):3235–3240. doi:10.1016/j.biombioe.2011.04.039

Kittikun HP, Prasertsan P, Srisuwan G, Krause A (2000) Environmental management for palm oil mill. In: Internet Conference on Material Flow Analysis of Integrated Bio-System

Lam MK, Lee KT, Mohamed AR (2009) Life cycle assessment for the production of biodiesel: a case study in Malaysia for palm oil versus jatropha oil. Biofuels Bioprod Bioref 3(6):601–612. doi:10.1002/bbb.182

Levasseur A, Lesage P, Margni M, Samson R (2012) Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J Ind Ecol. doi:10.1111/j.1530-9290.2012.00503.x

Malins C (2012) Comments of the ICCT on EPA palm oil pathway NODA. International Council on Clean Transportation, Washington San Francisco

Manik Y, Halog A (2013) A meta-analytic review of life cycle assessment and flow analyses studies of palm oil biodiesel. Integr Environ Assess Manag 9(1):134–141. doi:10.1002/ieam.1362

Melling L, Hatano R, Goh KJ (2005) Global warming potential from soils in tropical peatland of Sarawak, Malaysia. Phyton-Annales Rei Botanicae 45(4):275–284

Melling L, Hatano R, Goh KJ, Inioue T (2006) Greenhouse gas fluxes from three ecosystems in tropical peatland of Sarawak, Malaysia. Paper presented at the 18th World Congress of Soil Science, Philadelphia

Melling L, Goh KJ, Bouvais C, Hatano R (2010) Carbon flow and budget in a young mature oil palm agroecosystem on deep tropical peat. http://www.geog.le.ac.uk/carbopeat/media/pdf/yogyapapers/p43.pdf.

Müller-Wenk R, Brandão M (2010) Climatic impact of land use in LCA—carbon transfers between vegetation/soil and air. Int J Life Cycle Assess 15(2):172–182. doi:10.1007/s11367-009-0144-y

Ng SK, Thamboo S (1967) Nutrient content of oil palms in Malaya. Malays Agric J 46:3–45

Ng S, Thamboo S, De Souza P (1968) Nutrient content of oil palms in Malaya II. Nutrient in vegetative tissues. Malays Agric J 46:332–391

O’Hare M, Delucchi M, Edwards R, Fritsche U, Gibbs H, Hertel T, Hill J, Kammen D, Laborde D, Marelli L, Mulligan D, Plevin R, Tyner W (2011) Comment on “Indirect land use change for biofuels: testing predictions and improving analytical methodologies” by Kim and Dale: statistical reliability and the definition of the indirect land use change (iLUC) issue. Biomass Bioenergy 35(10):4485–4487. doi:10.1016/j.biombioe.2011.08.004

Papong S, Chom-In T, Noksa-nga S, Malakul P (2010) Life cycle energy efficiency and potentials of biodiesel production from palm oil in Thailand. Energy Policy 38(1):226–233

Pleanjai S, Gheewala SH (2009) Full chain energy analysis of biodiesel production from palm oil in Thailand. Appl Energy 86(Supplement 1):S209–S214

Pleanjai S, Gheewala S, Garivait S (2004) Environmental evaluation of biodiesel production from palm oil in a life cycle perspective. The Joint International Confernce on “Sustainable Energy and Environment (SEE)”, Hua Tin, pp 604–608

Poh PE, Chong MF (2009) Development of anaerobic digestion methods for palm oil mill effluent (POME) treatment. Bioresour Technol 100(1):1–9. doi:10.1016/j.biortech.2008.06.022

Rafflegeau S, Michel-Dounias I, Tailliez B, Ndigui B, Papy F (2010) Unexpected N and K nutrition diagnosis in oil palm smallholdings using references of high-yielding industrial plantations. Agron Sustain Dev 30(4):777–787. doi:10.1051/agro/2010019

Rettenmaier N, Reinhardt G, Muench J, Gaertner S (2007) Datenprojekt “Nachwachsende Rohstoffe”. IFEU, Heidelberg-Karlsruhe

Saikku L, Soimakallio S, Pingoud K (2012) Attributing land-use change carbon emissions to exported biomass. Environ Impact Assess Rev 37:47–54. doi:10.1016/j.eiar.2012.03.006

Schmidt JH (2004) The importance of system boundaries for LCA on large material flows of vegetable oils. Fourth World SETAC Congress, Portland

Secchi S, Kurkalova L, Gassman PW, Hart C (2011) Land use change in a biofuels hotspot: the case of Iowa, USA. Biomass Bioenergy 35(6):2391–2400

Siriwardhana M, Opathella GKC, Jha MK (2009) Bio-diesel: Initiatives, potential and prospects in Thailand: A review. Energy Policy 37(2):554–559

Stichnothe H, Schuchardt F (2010) Comparison of different treatment options for palm oil production waste on a life cycle basis. Int J Life Cycle Assess 15(9):907–915. doi:10.1007/s11367-010-0223-0

Stichnothe H, Schuchardt F (2011) Life cycle assessment of two palm oil production systems. Biomass Bioenergy 35(9):3976–3984. doi:10.1016/j.biombioe.2011.06.001

Subramaniam V, Ngan MA, May CY, Sulaiman NMN (2008) Environmental performance of the milling process of malaysian palm Oil using the life cycle assessment approach. Am J Environ Sci 208(4):310–315

Sulaiman F, Abdullah N, Gerhauser H, Shariff A (2011) An outlook of Malaysian energy, oil palm industry and its utilization of wastes as useful resources. Biomass Bioenergy 35(9):3775–3786. doi:10.1016/j.biombioe.2011.06.018

Tarmizi AM, Mohd Tayeb D (2006) Nutrient demands of Tenera oil palm planted on islands of Malaysia. J Oil Palm Res 18(June):204–209

Tarmizi AM, Haron K, Omar W (2006) Environmental aspects of agronomic practices of oil palm plantation. International Oil Palm Conference, Nusa Dua, pp 60–77

Thamsiriroj T, Murphy JD (2009) Is it better to import palm oil from Thailand to produce biodiesel in Ireland than to produce biodiesel from indigenous Irish rape seed? Appl Energy 86(5):595–604

Thamsiriroj T, Murphy JD (2010a) Can rape seed biodiesel meet the European union sustainability criteria for biofuels? Energy Fuel 24(3):1720–1730. doi:10.1021/ef901432g

Thamsiriroj T, Murphy JD (2010b) How much of the target for biofuels can be met by biodiesel generated from residues in Ireland? Fuel 89(11):3579–3589

UNFCC (2010) Indicative simplified baseline and monitoring methodologies for selected small-scale CDM project activity categories

Wahid MB, Abdullah SNA, Henson IE (2005) Oil palm - Achievements and potential. Plant Prod Sci 8(3):288–297

Wan Zahari M, Sato J, Furuichi S, Azizan AR, Yunus M (2003) Commercial processing of oil palm fronds feed in Malaysia. In: Forages and feed resources in commercial livestock production systems. 8th meeting of the regional working group on grazing and feed resources for Southeast Asia, Kuala Lumpur, Malaysia. pp 59–65

Wicke B, Dornburg V, Faaij A, Junginger M (2007) A greenhouse gas balance of electricity production from co-firing palm oil products from Malaysia. vol Final Report. University Utrecht, Copernicus Institute, Department of Science, Technology and Society

Wicke B, Dornburg V, Junginger M, Faaij A (2008) Different palm oil production systems for energy purposes and their greenhouse gas implications. Biomass Bioenergy 32(12):1322–1337

Wulfert K, Darnoko D, Tobing PL, Yulisari R, Guritno P (2002) Treatment of POME in anaerobic fixed bed digesters. In: International Oil Palm Conference IOPC, pp 265–275

Yee KF, Tan KT, Abdullah AZ, Lee KT (2009) Life cycle assessment of palm biodiesel: Revealing facts and benefits for sustainability. Appl Energy 86:S189–S196

Yoshizaki T, Shirai Y, Hassan MA, Baharuddin AS, Raja Abdullah NM, Sulaiman A, Busu Z (2013) Improved economic viability of integrated biogas energy and compost production for sustainable palm oil mill management. J Clean Prod 44:1–7. doi:10.1016/j.jclepro.2012.12.007

Acknowledgments

This research was supported by funding from the International Bureau of the Federal Ministry of Education and Research in Germany (Project ID: 7017). We would like to thank the anonymous reviewers for their constructive criticism that has helped to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Hans-Jürgen Garvens

Rights and permissions

About this article

Cite this article

Stichnothe, H., Schuchardt, F. & Rahutomo, S. European renewable energy directive: Critical analysis of important default values and methods for calculating greenhouse gas (GHG) emissions of palm oil biodiesel. Int J Life Cycle Assess 19, 1294–1304 (2014). https://doi.org/10.1007/s11367-014-0738-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-014-0738-x