ABSTRACT

Purpose

To develop a technique of obtaining monoclinic polymorph of paracetamol suitable for direct compression without excipients.

Methods

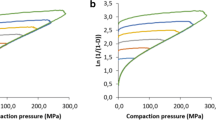

Preparation of spongy monoclinic paracetamol was based on quench-cooling of paracetamol solutions in water-acetone mixtures sprayed into a vessel with liquid nitrogen followed by removal of solvents by freeze-drying. X-ray powder diffraction was used to study annealing of quench-cooled solutions in “paracetamol-acetone-water” and “acetone-water” systems and to find optimum conditions for obtaining fine particles of pure monoclinic paracetamol. Samples were characterized by electron microscopy; compression properties were measured.

Results

The preparation technique gave fine monoclinic paracetamol powder containing agglomerates (30–200 μm) composed of flat particles (linear sizes 1–10 μm, the thickness 60–150 nm). The spongy sample was suitable for direct compression without excipients, stable on storage, and mechanically robust. Mechanically stable tablets pressed from the spongy sample were better soluble in water than commercially available tablets of paracetamol with excipients.

Conclusions

The proposed method gave spongy monoclinic paracetamol samples with improved properties. For inexpensive paracetamol, the method may not yield economic advantage. However, the same method based on freeze-drying solutions in mixed aqueous-organic solvents can be used to prepare new improved forms of other molecular solids for pharmaceutical applications.

Similar content being viewed by others

REFERENCES

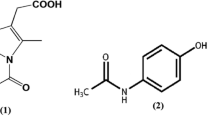

Boldyreva EV, Drebushchak VA, Paukov IE, Kovalevskaya YA, Drebushchak TN. DSC and adiabatic calorimetry study of the polymorphs of paracetamol - an old problem revisited. J Therm Anal Calorim. 2004;77:607–23.

Haisa M, Kashino S, Kawai R, Maeda H. The monoclinic form of p-hydroxyacetanilamide. Acta Crystallogr. 1976;B32:1283–5.

Nichols G, Frampton CS. Physicochemical characterization of the orthorhombic polymorph of paracetamol crystallized from solution. J Pharm Sci. 1998;87:684–93.

Joiris E, Di Martino P, Berneron C, Guyot-Hermann AM, Guyot JC. Compression behavior of orthorhombic paracetamol. Pharm Res. 1998;15:1122–30.

Haisa M, Kashino S, Kawai R, Maeda H. The Orthorombic form of p-Hydroxyacetanilamide. Acta Crystallogr. 1974;B30:2510–2.

Politov AA, Kostrovskii VG, Boldyrev VV. Conditions of preparation and crystallization of amorphous paracetamol. Russ J Phys Chem. 2001;75:1903–11.

Mikhailenko MA. Growth of large single crystals of the orthorhombic paracetamol. J Cryst Growth. 2004;265:616–8.

Kachrimanis K, Fucke K, Noisternig M, Siebenhaar B, Griesser UJ. Effects of moisture and residual solvent on the phase stability of orthorhombic paracetamol. Pharm Res. 2008;25:1440–9.

Espeau P, Ceolin R, Tamarit JL, Perrin MA, Gauchi JP, Leveiller F. Polymorphism of paracetamol: relative stabilities of the monoclinic and orthorhombic phases inferred from topological pressure-temperature and temperature-volume phase diagrams. J Pharm Sci. 2005;94:524–39.

Boldyreva EV, Shakhtshneider TP, Ahsbahs H, Sowa H, Uchtmann H. Effect of high pressure on the polymorphs of paracetamol. J Therm Anal Calorim. 2002;68:437–52.

Saska Z, Dredan J, Balogh E, Luhn O, Shafir G, Antal I. Effect of isomalt as novel binding agent on compressibility of poorly compactable paracetamol evaluated by factorial design. Powder Technol. 2010;201:123–9.

Wlosnewski JC, Kumpugdee-Vollrath M, Sriamornsak P. Effect of drying technique and disintegrant on physical properties and drug release behavior of microcrystalline cellulose-based pellets prepared by extrusion/spheronization. Chem Eng Res Des. 2010;88:100–8.

Mohammed H, Briscoe BJ, Pitt KG. The intrinsic nature and the coherence of compacted pure pharmaceutical tablets. Powder Technol. 2006;165:11–21.

Garekani HA, Ford JL, Rubinstein MH, Rajabi-Siahboomi AR. Highly compressible paracetamol: I: crystallization and characterization. Int J Pharm. 2000;208:87–99.

Gonnissen Y, Remon JP, Vervaet C. Development of directly compressible powders via co-spray drying. Eur J Pharm Biopharm. 2007;67:220–6.

Boateng JS, Matthews KH, Auffret AD, Humphrey MJ, Stevens HN, Eccleston GM. In vitro drug release studies of polymeric freeze-dried wafers and solvent-cast films using paracetamol as a model soluble drug. Int J Pharm. 2009;378:66–72.

Boateng JS, Auffret AD, Matthews KH, Humphrey MJ, Stevens HNE, Eccleston GM. Characterisation of freeze-dried wafers and solvent evaporated films as potential drug delivery systems to mucosal surfaces. Int J Pharm. 2010;389:24–31.

Lai HL. Abu’Khalil A, Craig DQM. The preparation and characterisation of drug-loaded alginate and chitosan sponges. Int J Pharm. 2003;251:175–81.

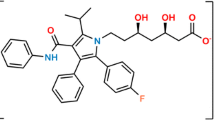

Karki S, Friscic T, Fabian L, Laity PR, Day GM, Jones W. Improving Mechanical Properties of Crystalline Solids by Cocrystal Formation: New Compressible Forms of Paracetamol. Adv Mater. 2009;21:3905–9.

Fachaux JM, Guyothermann AM, Guyot JC, Conflant P, Drache M, Veesler S, et al. Pure Paracetamol for Direct Compression.1. Development of Sintered-Like Crystals of Paracetamol. Powder Technol. 1995;82:123–8.

Levis SR, Deasy PB. Pharmaceutical applications of size reduced grades of surfactant co-processed microcrystalline cellulose. Int J Pharm. 2001;230:25–33.

Palmieri GF, Michelini S, Di Martino P, Martelli S. Polymers with pH-dependent solubility: possibility of use in the formulation of gastroresistant and controlled-release matrix tablets. Drug Dev Ind Pharm. 2000;26:837–45.

Palmieri GF, Bonacucina G, Di Martino P, Martelli S. Spray-drying as a method for microparticulate controlled release systems preparation: advantages and limits. I. Water-soluble drugs. Drug Dev Ind Pharm. 2001;27:195–204.

Hu JH, Johnston KP, Williams RO. Nanoparticle engineering processes for enhancing the dissolution rates of poorly water soluble drugs. Drug Dev Ind Pharm. 2004;30:233–45.

Chow AHL, Tong HHY, Chattopadhyay P, Shekunov BY. Particle engineering for pulmonary drug delivery. Pharm Res. 2007;24:411–37.

Liu JS. Physical characterization of pharmaceutical formulations in frozen and freeze-dried solid states: techniques and applications in freeze-drying development. Pharm Dev Technol. 2006;11:3–28.

Talegaonkar S, Khan AY, Khar RK, Ahmad FJ, Khan ZI. Development and characterization of paracetamol complexes with hydroxypropyl-beta-cyclodextrin. Iran J Pharm Res. 2007;6:95–9.

Paruta AN, Irani AS. Dielectric solubility profiles in dioxane-water mixtures for several antipyrectic drugs. J Pharm Sci. 1965;54:1334–8.

Prakongpan S, Nagai T. Pharmaceutical Interactions in Dosage Forms and Processing.45. Solubility of Acetaminophen in Cosolvents. Chem. Pharm Bull. 1984;32:340–3.

Granberg RA, Rasmuson AC. Solubility of paracetamol in binary and ternary mixtures of water plus acetone plus toluene. J Chem Eng Data. 2000;45:478–83.

Dyadin YA, Bondaryuk IV, Zhurko FV. Clathrate hydrates at high pressures. In: Atwood JL, Davies JED, MacNicol DD, editors. Inclusion compounds. V.5. Oxford: Oxford University Press; 1991. p. 214–75.

Ancharov AI, Manakov AY, Mezentsev NA, Tolochko BP, Sheromov MA, Tsukanov VM. New station at the 4th beamline of the VEPP-3 storage ring. Nucl Instrum Methods Phys Res Sect A-Accel Spectrom Dect Assoc Equip. 2001;470:80–3.

Hammersley AP. “Fit2D Programm, 1987–2003”, European Synchrotron Research Facility.

Rodriguez-Carvajal J. FULLPROF: A program for rietveld refinement and pattern matching analysis. Abstracts of the Satellite Meeting on Powder Diffraction of the XV Congress of the IUCr. Toulouse, France, 1990. p. 127.

Rupp B. XLAT—a microcomputer program for the refinement of cell constants. Scripta Metallurgica. 1988;22:1.

Fell JT, Newton JM. Determination of tablet strength by the diametral-compression test. J Pharm Sci. 1970;5:688–91.

Malsam J, Aksan A. Hydrogen bonding and compartmentalization of water in supercooled and frozen aqueous acetone solutions. J Phys Chem B. 2010;114:4238–45.

Allan DR, Clark SJ, Ibberson RM, Parsons S, Pulham CR, Sawyer L. The influence of pressure and temperature on the crystal structure of acetone. Chem Commun. 1999;751–2.

Peterson ML, McIlroy D, Shaw P, Mustonen JP, Oliveira M, Almarsson O. Crystallization and transformation of acetaminophen trihydrate. Cryst Growth Des. 2003;3:761–5.

Baldyga J, Kubicki D, Shekunov BY, Smith KB. Mixing effects on particle formation in supercritical fluids. Chem Eng Res Des. 2010;88:1131–41.

Shi LM, Sun CC. Transforming powder mechanical properties by core/shell structure: compressible sand. J Pharm Sci. 2010;99:4458–62.

Hüttenrauch R, Fricke S, Zielke P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985;302–6.

ACKNOWLEDGMENTS & DISCLOSURES

This work was supported by RUX0-008-NO-06, the Program “Fundamental Science for Medical Applications,” FASI State Contract of RF no. 02.740.11.5102, the Project 21.44 of the Program “Nanomaterials” of the Presidium of RAS, the Integration Projects no. 13 and no. 109 of SB RAS, and Russian Ministry of Education and Science (State Contract of RF no. 14.740.11.1023). A.G.O. and A.I.A. thank CRDF (projects Y5-C-08-09, Y5-C-08-01) for financial support. We thank Dr. M.S. Melgunov for the specific surface area measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ogienko, A.G., Boldyreva, E.V., Yu Manakov, A. et al. A New Method of Producing Monoclinic Paracetamol Suitable for Direct Compression. Pharm Res 28, 3116–3127 (2011). https://doi.org/10.1007/s11095-011-0502-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-011-0502-x