ABSTRACT

Purpose

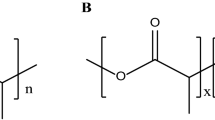

To assess the feasibility of hot-melt extrusion (HME) for preparing implants based on protein/poly(lactide-co-glycolide) (PLGA) formulations with special emphasis on protein stability, burst release and release completeness.

Method

Model protein (lysozyme)-loaded PLGA implants were prepared with a screw extruder and a self-built syringe-die device as a rapid screening tool for HME formulation optimization. Lysozyme stability was determined using DSC, FTIR, HPLC and biological activity. The simultaneous effect of lysozyme and PEG loadings was investigated to obtain optimized formulations with high drug loading but low initial release.

Results

Lysozyme was recovered from implants with full biological activity after HME. The release from all implants reached the 100% value in 60–80 days with nearly complete enzymatic activity of the last fraction of released lysozyme. Pure PLGA implants with up to 20% lysozyme loading could be formulated without initial burst. The incorporation of PEG 400 reduced the initial burst at drug loadings in excess of 20%.

Conclusion

A complete lysozyme recovery in active form with a burst-free and complete release from PLGA implants prepared by hot-melt extrusion was obtained. This is in contrast to many reported microparticulate lysozyme-PLGA systems and suggests the great potential of hot-melt extrusion for the preparation of protein-PLGA implants.

Similar content being viewed by others

REFERENCES

Giteau A, Venier-Julienne MC, Aubert-Pouëssel A, Benoit JP. How to achieve sustained and complete protein release from PLGA-based microparticles? Int J Pharm. 2008;350:14–26.

Aubert-Pouëssel A, Bibby DC, Venier-Julienne MC, Hindre F, Benoît JP. A novel in vitro delivery system for assessing the biological integrity of protein upon release from PLGA microspheres. Pharm Res. 2002;19:1046–51.

Ghassemi AH, van Steenbergen MJ, Talsma H, van Nostrum CF, Jiskoot W, Crommelin DJA, et al. Preparation and characterization of protein loaded microspheres based on a hydroxylated aliphatic polyester, poly(lactic-co-hydroxymethyl glycolic acid). J Control Release. 2009;138:57–63.

Giteau A, Venier-Julienne MC, Marchal S, Courthaudon JL, Sergent M, Montero-Menei C, et al. Reversible protein precipitation to ensure stability during encapsulation within PLGA microspheres. Eur J Pharm Biopharm. 2008;70:127–36.

Kokai LE, Tan H, Jhunjhunwala S, Little SR, Frank JW, Marra KG. Protein bioactivity and polymer orientation is affected by stabilizer incorporation for double-walled microspheres. J Control Release. In Press, Uncorrected Proof.

Lee ES, Park KH, Park IS, Na K. Glycol chitosan as a stabilizer for protein encapsulated into poly(lactide-co-glycolide) microparticle. Int J Pharm. 2007;338:310–6.

Taluja A, Bae YH. Role of a novel multifunctional excipient poly(ethylene glycol)-block-oligo(vinyl sulfadimethoxine) in controlled release of lysozyme from PLGA microspheres. Int J Pharm. 2008;358:50–9.

Van De Weert M, Hoechstetter J, Hennink WE, Crommelin DJA. The effect of a water/organic solvent interface on the structural stability of lysozyme. J Control Release. 2000;68:351–9.

Diwan M, Park TG. Pegylation enhances protein stability during encapsulation in PLGA microspheres. J Control Release. 2001;73:233–44.

Jain RA. The manufacturing techniques of various drug loaded biodegradable poly(lactide-co-glycolide) (PLGA) devices. Biomaterials. 2000;21:2475–90.

Pérez C, Griebenow K. Improved activity and stability of lysozyme at the water/CH2Cl2 interface: enzyme unfolding and aggregation and its prevention by polyols. J Pharm Pharmacol. 2001;53:1217–26.

Van De Weert M, Hennink WE, Jiskoot W. Protein instability in poly(lactic-co-glycolic acid) microparticles. Pharm Res. 2000;17:1159–67.

Prestrelski SJ, Tedeschi N, Arakawa T, Carpenter JF. Dehydration-induced conformational transitions in proteins and their inhibition by stabilizers. Biophys J. 1993;65:661–71.

Ghaderi R, Carlfors J. Biological activity of lysozyme after entrapment in poly (d, l-lactide-co-glycolide)-microspheres. Pharm Res. 1997;14:1556–62.

Pérez C, Castellanos IJ, Costantino HR, Al-Azzam W, Griebenow K. Recent trends in stabilizing protein structure upon encapsulation and release from bioerodible polymers. J Pharm Pharmacol. 2002;54:301–13.

Hageman MJ. The role of moisture in protein stability. Drug Dev Ind Pharm. 1988;14:2047–70.

Bell LN, Hageman MJ, Muraoka LM. Thermally induced denaturation of lyophilized bovine somatotropin and lysozyme as impacted by moisture and excipients. J Pharm Sci. 1995;84:707–12.

Chien-Hua N, Yuan-Yuan C. FDA perspective on peptide formulation and stability issues. J Pharm Sci. 1998;87:1331–4.

Rothen-Weinhold A, Oudry N, Schwach-Abdellaoui K, Frutiger-Hughes S, Hughes GJ, Jeannerat D, et al. Formation of peptide impurities in polyester matrices during implant manufacturing. Eur J Pharm Biopharm. 2000;49:253–7.

Park TG, Lee HY, Nam YS. A new preparation method for protein loaded poly(D, L-lactic-co-glycolic acid) microspheres and protein release mechanism study. J Control Release. 1998;55:181–91.

Van De Weert M, Van’T Hof R, Van Der Weerd J, Heeren RMA, Posthuma G, Hennink WE, et al. Lysozyme distribution and conformation in a biodegradable polymer matrix as determined by FTIR techniques. J Control Release. 2000;68:31–40.

Kang F, Singh J. Effect of additives on the release of a model protein from PLGA microspheres. AAPS PharmSciTech. 2001;2.

Jiang W, Schwendeman SP. Stabilization and controlled release of bovine serum albumin encapsulated in poly(D, L-lactide) and poly(ethylene glycol) microsphere blends. Pharm Res. 2001;18:878–85.

Malzert A, Boury F, Renard D, Robert P, Lavenant L, Benoît JP, et al. Spectroscopic studies on poly(ethylene glycol)-lysozyme interactions. Int J Pharm. 2003;260:175–86.

Körber M, Bodmeier R. Development of an in situ forming PLGA drug delivery system. I. Characterization of a non-aqueous protein precipitation. Eur J Pharm Sci. 2008;35:283–92.

Claudy P, Letoffe JM, Bayol A, Bonnet MC, Maurizot JC. Denaturation versus pH of lysozyme and biosynthetic human growth hormone by differential scanning calorimetry and circular dichroism: a comparative study. Thermochim Acta. 1992;207:227–37.

Shugar D. The measurement of lysozyme activity and the ultra-violet inactivation of lysozyme. BBA–Biochim Biophys Acta. 1952;8:302–9.

Wang J, Chua KM, Wang CH. Stabilization and encapsulation of human immunoglobulin G into biodegradable microspheres. J Colloid Interface Sci. 2004;271:92–101.

Elkordy AA, Forbes RT, Barry BW. Integrity of crystalline lysozyme exceeds that of a spray-dried form. Int J Pharm. 2002;247:79–90.

Hill JJ, Shalaev EY, Zografi G. Thermodynamic and dynamic factors involved in the stability of native protein structure in amorphous solids in relation to levels of hydration. J Pharm Sci. 2005;94:1636–67.

Schwendeman SP, Costantino HR, Gupta RK, Langer R. Peptide, protein and vaccine delivery from implantable polymeric systems: Progress and challenges. Controlled Drug Delivery: Challenges and Strategies; 1997. p. 229–267.

Ding QB, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–8.

Akdogan H. Pressure, torque, and energy responses of a twin screw extruder at high moisture contents. Food Res Int. 1996;29:423–9.

Warfield RW. Compressibility of bulk polymers. Polym Eng Sci. 1966;6:176–80.

Tomizawa H, Yamada H, Ueda T, Imoto T. Isolation and characterization of 101-succinimide lysozyme that possesses the cyclic imide at Asp101-Gly102. Biochemistry. 1994;33:8770–4.

Ritger P, Peppas N. A simple equation for description of solute release I. Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. J Control Release. 1987;5:23–36.

Bezemer JM, Radersma R, Grijpma DW, Dijkstra PJ, Van Blitterswijk CA, Feijen J. Microspheres for protein delivery prepared from amphiphilic multiblock copolymers 2. Modulation of release rate. J Control Release. 2000;67:249–60.

ACKNOWLEDGMENT

The financial support of the German Academic Exchange Service (DAAD) for Zahra Ghalanbor Ph.D. studies and the support of Laszlo David (Department of Mathematics and Informatics, Freie Universität Berlin) with the MATLAB® code are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 303 kb)

Rights and permissions

About this article

Cite this article

Ghalanbor, Z., Körber, M. & Bodmeier, R. Improved Lysozyme Stability and Release Properties of Poly(lactide-co-glycolide) Implants Prepared by Hot-Melt Extrusion. Pharm Res 27, 371–379 (2010). https://doi.org/10.1007/s11095-009-0033-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-009-0033-x