Abstract

Novel zein/tet (tetradecane) and zein/tet/APC (aqueous potassium chloride) micro-encapsulated functional materials were synthesized using a microwave-assisted encapsulation technique. This technique can produce microcapsules in a very short time. In this study, we optimized the methodology used to obtain micro-encapsulation structures based on zein (a maize protein). Zein was mixed with functional materials in ratios of 1:1 and 1:2 (w/v) using ethanol as a solvent. After sonication, each mixture was treated up to 550 s at a power of 450 W in a microwave oven. Subsequently, nitrogen was pumped into the solution for 1 h to remove any residual ethanol from the system and the samples were freeze-dried to yield the dry powder. The thermal performance was analyzed using differential scanning calorimetry and thermogravimetric analysis. The encapsulation morphology and chemical structure were analyzed using scanning electron microscopy, Fourier transform infrared spectroscopy, and X-ray diffraction. Tetradecane was found to be properly encapsulated in the microstructure of zein under two different conditions with an average capsule diameter of 13950 nm. The melting point, crystallization point, and latent heat of encapsulated zein/tet are 4.95, 0.68 °C, and 107 J g−1, respectively. Thermal cycling tests indicated that zein/tet and zein/tet/APC have good thermal stability with negligible changes in their melting and crystallization temperatures. Heat management with tet has been modified using potassium chloride to support a suitable temperature range for food packaging. The encapsulated materials can be potentially used for temperature control during the transport of temperature-sensitive products.

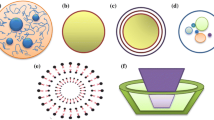

Graphical Abstract

Similar content being viewed by others

References

Li G. Energy and exergy performance assessments for latent heat thermal energy storage systems. Renew Sustain Energy Rev. 2015;51:926–54. doi:10.1016/j.rser.2015.06.052.

Li G, Zheng X. Thermal energy storage system integration forms for a sustainable future. Renew Sustain Energy Rev. 2016;62:736–57. doi:10.1016/j.rser.2016.04.076.

Li G, Thesis. Review of thermal energy storage technologies and experimental investigation of adsorption thermal energy storage for residential application. Master. 2013;1.

Jin Y, Lee W, Musina Z, Ding Y. A one-step method for producing microencapsulated phase change materials. Particuology. 2010;8:588–90. doi:10.1016/j.partic.2010.07.009.

Li G, Hwang Y, Radermacher R. Review of cold storage materials for air conditioning application. Int J Refrig. 2012;35:2053–77. doi:10.1016/j.ijrefrig.2012.06.003.

Li G. Comprehensive investigation of transport refrigeration life cycle climate performance. Sustain Energy Technol Assess. 2017;21:33–49. doi:10.1016/j.seta.2017.04.002.

Chaiyasat P, Noppalit S, Okubo M, Chaiyasat A. Do encapsulated heat storage materials really retain their original thermal properties? Phys Chem Chem Phys 2015;17:1053–9. http://www.ncbi.nlm.nih.gov/pubmed/25412246.

Fang G, Li H, Yang F, Liu X, Wu S. Preparation and characterization of nano-encapsulated n-tetradecane as phase change material for thermal energy storage. Chem Eng J. 2009;153:217–21. doi:10.1016/j.cej.2009.06.019.

Alkan C, Sari A, Karaipekli A. Preparation, thermal properties and thermal reliability of microencapsulated n-eicosane as novel phase change material for thermal energy storage. Energy Convers Manag. 2011;52:687–92. doi:10.1016/j.enconman.2010.07.047.

Tyagi VV, Kaushik SC, Tyagi SK, Akiyama T. Development of phase change materials based microencapsulated technology for buildings: a review. Renew Sustain Energy Rev. 2011;15:1373–91. doi:10.1016/j.rser.2010.10.006.

Sharma A, Shukla A, Chen CR, Wu TN. Development of phase change materials (PCMs) for low temperature energy storage applications. Sustain Energy Technol Assess. 2014;7:17–21. doi:10.1016/j.seta.2014.02.009.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev. 2009;13:318–45. doi:10.1016/j.rser.2007.10.005.

Lin WT, Huang DS, Lin MT, Lai CM. The thermal evaluation of the substrate mixed with microencapsulated phase change materials for MEMS packaging applications. Microsyst Technol. 2011;17:693–9. doi:10.1007/s00542-010-1154-1.

Li G, Hwang Y, Radermacher R. Cold thermal energy storage materials and applications toward sustainability. In: Zhang X, Dincer I, editors. Energy solutions to combat global warming. Berlin: Springer; 2017. p. 67–117. doi:10.1007/978-3-319-26950-4_4.

Li G, Liu D, Xie Y. Study on thermal properties of TBAB–THF hydrate mixture for cold storage by DSC. J Therm Anal Calorim. 2010;102:819–26. doi:10.1007/s10973-010-0796-7.

Perez-Masia R, Lopez-Rubio A, Fabra MJ, Lagaron JM. Biodegradable polyester-based heat management materials of interest in refrigeration and smart packaging coatings. J Appl Polym Sci. 2013;130:3251–62. doi:10.1002/app.39555.

Zeng JL, Sun SL, Zhou L, Chen YH, Shu L, Yu LP, Zhu L, Song LB, Cao Z, Sun LX. Preparation, morphology and thermal properties of microencapsulated palmitic acid phase change material with polyaniline shells. J Therm Anal Calorim. 2017;129:1583–92. doi:10.1007/s10973-017-6352-y.

Quispe-Condori S, Saldaña MDA, Temelli F. Microencapsulation of flax oil with zein using spray and freeze drying. LWT—Food Sci Technol. 2011;44:1880–7. doi:10.1016/j.lwt.2011.01.005.

Fernandez A, Torres-Giner S, Lagaron JM. Novel route to stabilization of bioactive antioxidants by encapsulation in electrospun fibers of zein prolamine. Food Hydrocoll. 2009;23:1427–32. doi:10.1016/j.foodhyd.2008.10.011.

Parris N, Cooke PH, Hicks KB. Encapsulation of essential oils in zein nanosperical particles. J Agric Food Chem. 2005;53:4788–92. doi:10.1021/jf040492p.

Gaikwad KK, Singh S, Lee YS. A pyrogallol-coated modified LDPE film as an oxygen scavenging film for active packaging materials. Prog Org Coat. 2017;111:186–95. doi:10.1016/j.porgcoat.2017.05.016.

Gaikwad KK, Lee YS. Effect of storage conditions on the absorption kinetics of non-metallic oxygen scavenger suitable for moist food packaging. J Food Meas Charact. 2017;. doi:10.1007/s11694-017-9470-0.

Wu Y, Luo Y, Wang Q. Antioxidant and antimicrobial properties of essential oils encapsulated in zein nanoparticles prepared by liquid-liquid dispersion method. LWT—Food Sci Technol. 2012;48:283–90. doi:10.1016/j.lwt.2012.03.027.

Luo Y, Zhang B, Whent M, Yu LL, Wang Q. Preparation and characterization of zein/chitosan complex for encapsulation of α-tocopherol, and its in vitro controlled release study. Colloids Surf B Biointerfaces. 2011;85:145–52. doi:10.1016/j.colsurfb.2011.02.020.

Neo YP, Ray S, Jin J, Gizdavic-Nikolaidis M, Nieuwoudt MK, Liu D, Quek SY. Encapsulation of food grade antioxidant in natural biopolymer by electrospinning technique: a physicochemical study based on zein–gallic acid system. Food Chem. 2013;136:1013–21. doi:10.1016/j.foodchem.2012.09.010.

Gomez-Estaca J, Balaguer MP, Gavara R, Hernandez-Munoz P. Formation of zein nanoparticles by electrohydrodynamic atomization: effect of the main processing variables and suitability for encapsulating the food coloring and active ingredient curcumin. Food Hydrocoll. 2012;28:82–91. doi:10.1016/j.foodhyd.2011.11.013.

Bo H, Gustafsson EM, Setterwall F. Tetradecane and hexadecane binary mixtures as phase change materials (PCMs) for cool storage in district cooling systems. Energy. 1999;24:1015–28. doi:10.1016/S0360-5442(99)00055-9.

Gülseren I, Coupland JN. The effect of emulsifier type and droplet size on phase transitions in emulsified even-numbered n-alkanes. J Am Oil Chem Soc. 2007;84:621–9. doi:10.1007/s11746-007-1093-x.

Pérez-Masiá R, López-Rubio A, Lagarón JM. Development of zein-based heat-management structures for smart food packaging. Food Hydrocoll. 2013;30:182–91. doi:10.1016/j.foodhyd.2012.05.010.

Fang Y, Yu H, Wan W, Gao X, Zhang Z. Preparation and thermal performance of polystyrene/n-tetradecane composite nanoencapsulated cold energy storage phase change materials. Energy Convers Manag. 2013;76:430–6. doi:10.1016/j.enconman.2013.07.060.

Pérez-Masiá R, López-Rubio A, Fabra MJ, Lagaron JM. Use of electrohydrodynamic processing to develop nanostructured materials for the preservation of the cold chain. Innov Food Sci Emerg Technol. 2014;26:415–23. doi:10.1016/j.ifset.2014.10.010.

Li G, Li W. Synthesis and characterization of microencapsulated n-octadecane with hybrid shells containing 3-(trimethoxysilyl) propyl methacrylate and methyl methacrylate. J Therm Anal Calorim. 2017;129:915–24. doi:10.1007/s10973-017-6220-9.

Onder E, Sarier N, Cimen E. Encapsulation of phase change materials by complex coacervation to improve thermal performances of woven fabrics. Thermochim Acta. 2007;467:63–72. doi:10.1016/j.tca.2007.11.007.

Sarier N, Onder E. Thermal characteristics of polyurethane foams incorporated with phase change materials. Thermochim Acta. 2007;454:90–8. doi:10.1016/j.tca.2006.12.024.

Singh S, Gaikwad KK, Lee M, Lee YS. Thermally buffered corrugated packaging for preserving the postharvest freshness of mushrooms (Agaricus bispours). J Food Eng. 2017;216:11–9. doi:10.1016/j.jfoodeng.2017.07.013.

Acknowledgements

This work was supported by the Korea Institute of Planning and Evaluation for Technology in Food, Agriculture, Forestry, and Fisheries (IPET) through the High Value-Added Food Technology Development Program, funded by the Ministry of Agriculture, Food, and Rural Affairs (MAFRA) (316067-3).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., Gaikwad, K.K., Lee, M. et al. Microwave-assisted micro-encapsulation of phase change material using zein for smart food packaging applications. J Therm Anal Calorim 131, 2187–2195 (2018). https://doi.org/10.1007/s10973-017-6768-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6768-4