Abstract

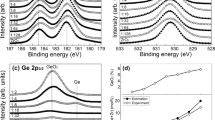

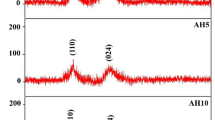

In current work, the microstructure and optical and electrical properties of sol–gel-derived Gd-doped ZrO2 gate dielectric thin films as functions of annealing temperatures were systemically investigated. Analyzes by x-ray diffraction have indicated that the 240 °C-baked sample as well as those samples annealed at lower temperatures keep amorphous state. In the sample annealed at 500 °C, however, the amorphous phase disappears and tetragonal ZrO2 is formed. Measurements from ultraviolet-visible spectroscopy (UV/Vis) have demonstrated that transmittance of all samples in the visible region is approximately 80% and the increase in band gap energy has been found with increasing the annealing temperature. Electrical properties of all samples based on Al/Si/ZrGdOx/Al MOS capacitor have been investigated by using semiconductor device analyzer. Through the analysis and calculation of the electrical characteristic curves, solution-processed Al/ZrGdOx/Si/Al capacitor shows improved performances at a annealing temperature of 400 °C, such as high dielectric constant (k) of 16.56, lowest oxidation charge density (Q ox) of −0.74 × 1012 cm−2, and boundary trap oxidation charge density (N bt) of 3.17 × 1012 cm−2. In addition, the leakage current mechanism for 400 °C-annealed sample has been discussed in detail.

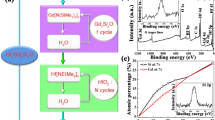

Graphical Abstract

solution-processed Gd-doped ZrO2 gate dielectric films were realized. Al/ZrGdOx/Si/Al capacitor shows optimized and improved performances at a annealing temperature of 400 °C.

Similar content being viewed by others

References

He G, Zhu LQ, Liu M, Fang Q, Zhang LD (2007) Appl Surf Sci 253:3413–3418

He G, Fang Q, Liu M, Zhu LQ, Zhang LD (2004) J Cryst Growth 268:155–162

He G, Deng B, Liu M, Ma YQ, Chen XS, Lv JG, Shi SW, Song XP, Sun ZQ (2013) Sci Adv Mater 5:709–712

Jones AC, Aspinall HC, Chalker PR, Potter RJ, Kukli K, Rahtu A, Ritala M, LeskeläM (2004) J Mater Chem 14:3101–3112

Wilk GD, Wallace RM, Anthony JM (2001) J Appl Phys 89:5243–5275

Liao L, Bai JW, Lin YC, Qu YQ, Huang Y, Duan XF (2010) Adv Mater 22:1941–1945

Zhang W, Cui Y, Hu ZG, Yu WL, Sun J, Xu N, Ying ZF, Wu JD (2012) Thin Solid Films 520:6361–6367

Xiong Y, Tu H, Du J, Ji M, Zhang X, Wang L, (2010) Appl Phys Lett 97:012901

Xiao DQ, He G, Lv JG, Wang PH, Liu M, Gao J, Jin P, Jiang SS, Li WD, Sun ZQ (2017) J Alloys Compd 699:415–420

Jõgi Indrek, Tamm A, Kukli K, Kemell M, Lu J, Sajavaara T, Ritala M, Leskeläb M (2010) J Electrochem Soc 157:G202–G210

Cho MH, Moon DW, Park SA, RhoYS, Kim YK, Jeong K, Chang CH, Gu JH, Lee JH, Choi SY (2004) Appl Phys Lett 84:678–680

Venkatachalam DK, Bradby JE, Saleh MN, Ruffell S, Elliman RG (2011) J Appl Phys 110:043527

Iizuka H, Yokoo K, Ono S (1992) Appl Phys Lett 61:2978–2980

Ritala M, Kukli K, Rahtu A (2000) Science 288:319–321

Zhu SL, Wang FH, Lou HY, Wu WT (1995) Surf Coat Technol 71:9–15

Liu A, Liu G, Zhu H, Shin B, Fortunato E, Martions R, Shan F, (2016) Appl Phys Lett 108:233506

Jin P, He G, Fang ZB, Liu M, Xiao DQ, Gao J, Jiang SS, Li WD, Sun ZQ, Zhang M (2017) Ceram Int 43:3101–3106

Chang SM, Doong RA (2005) Chem Mater 17:4837–4844

Chaneliere C, Four S, Autran JL, Devine RAB, Sandler NP (1998) J Appl Phys 83:4823–4829

Jo SJ, Ha JS, Park NK, Kang DK, Kim BH (2006) Thin Solid Films 513:253–257

Park JH, Yoo YB, Lee KH, Jang WS, Oh JY, Chae SS, Baik HK (2013) ACS Appl Mater Interfaces 5:410–417

Tan TT, Liu ZT, Lu HC, Liu WT, Yan F, Zhang WH (2009) Appl Phys A 97:475–479

Ananthakumar R, Sang JK (2012) J Alloy Compd 544:115–119

Liang LP, Sheng YG, Xu Y, Wu D, Sun YH (2007) Thin Solid Films 515:7765–7771

Liu M, Fang Q, He G, Li L, Zhu LQ, Li GH, Zhang LD (2006) Appl Phys Lett 88:192904-192904-3

Fan JB, Liu HX, Kuang QW, Gao B, Ma F, Hao Y (2012) Microelectron Reliab 52:1043–1049

Das PS, Biswas A (2011) Microelectron Eng 88:282–286

Lai PT, Chakraborty S, Chan CL, Cheng YC (2000) Appl Phys Lett 76:3744–3746

Zhang JQ, Li ZX, Zhou H, Ye C, Wang H (2014) Appl Surf Sci 294:58–65

Liu JW, Liao MY, Imura M, Tanaka A, Iwai H, Koide Y (2014) Sci Rep 4:6395

Liu JW, Liao MY, Imura M, Oosato H, Watanabe E, Koide Y, (2013) Appl Phys Lett 102:112910

Zhang JW, He G, Zhou L, Chen HS, Chen XS, Chen XF, Deng B, Lv JG, Sun ZQ (2014) J Alloy Comp 611:253–259

Chen F, Bin X, Hella C, Shi X, Gladfelter WL, Campbell SA (2004) Microelectron Eng 72:263–266

Quah HJ, Cheong KY (2012) J Alloys Compd 529:73–83

Quah HJ, Cheong KY, Hassan Z, Lockman Z (2011) J Mater Sci Mater Electron 22:583–591

Quah HJ, Lim WF, Cheong KY, Hassan Z, Lockman Z (2011) J Cryst Growth 326:2–8

Gao F, Lee SJ, Chi DZ, Balakumar SK, Wong DL, (2007) Appl Phys Lett 90:252904

Gao J, He G, Deng B, Xiao DX, Liu M, Jin P, Zheng CY, Sun ZQ (2016) J Alloy Compd 622:339–347

Chiu FC (2006) J Appl Phys 100:114102

Ding SJ, Zhang DW, Wang LK (2007) J Phys D 40:1072–1076

Acknowledgements

The authors acknowledge the support from National Natural Science Foundation of China (51572002,11474284), Technology Foundation for Selected Overseas Chinese Scholar, Ministry of Personnel of China (J05015131), Anhui Provincial Natural Science Foundation (1608085MA06).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhu, L., He, G., Sun, Z.Q. et al. Annealing temperature-dependent microstructure and optical and electrical properties of solution-derived Gd-doped ZrO2 high-k gate dielectrics. J Sol-Gel Sci Technol 83, 675–682 (2017). https://doi.org/10.1007/s10971-017-4468-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4468-y