Abstract

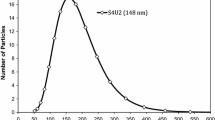

In this work, 1,2,3-trideoxy-4,6:5,7-bis-O-[(4-propylphenyl) methylene]-nonitol (TBPMN) was conscripted as the clarifying agent, the influence of the injection pressure on optical properties of PP were investigated, and results documented that increasing the injection pressure could not improve the transparency of the transparent PP. Thereafter, the crystallization behavior and morphological changes of transparent PP in condensed structure under different injection pressures were studied by the differential scanning calorimetry (DSC), the scanning electron microscopy (SEM) and the dynamic thermomechanical analysis (DMA), respectively, and results presented that change in injection pressure influence crystallization properties significantly. Besed on analyzing of the relationship between structure and optical properties, the effect of pressure on the optical properties was explained as follows: low injection pressure would be facilitated to the transparency of transparent PP, because under low injection pressure, the clarifier fiber could be dispersed uniformly and the network structure was formed and preserved well, and molecular chains of transparent PP was crystallized to the nanometer-level fiber on the surface of nucleation sites, which greatly reduces the scattering of light. However, increasing the injection pressure would promote the fiber itself accumulation into a scatterer point, which not only reduces the effect of the clarifier, but also causes the preferential arrangement of the PP molecules to produce an oriented structure due to strong external force and shearing action, thereby increasing light scattering.

Similar content being viewed by others

References

Ahmad Z, Kumar KD, Saroop M, Preschilla N, Biswas A, Bellare JR, Bhowmick AK (2010) Highly transparent thermoplastic elastomer from isotactic polypropylene and styrene/ethylene-butylene/styrene triblock copolymer: structure–property correlations. Polym Eng Sci 50:331–341. https://doi.org/10.1002/pen.21540

Clariant’s latest Cesa products target clear PP and improved PET, PLA recycling (2017). Addit Polym 6:1–2. https://doi.org/10.1016/s0306-3747(17)30080-5

Liang J, Ma Y, Wang F, Yang W (2010) Flexible, highly transparent, and conductive poly(3,4-ethylenedioxythiophene)-polypropylene composite films of Nanofibrillar morphology. Chem Mater 22(14):4254–4262. https://doi.org/10.1021/cm100940s

Schawe JEK, Budde F, Alig I (2018) Nucleation activity at high supercooling: sorbitol-type nucleating agents in polypropylene. Polymer 153:587–596. https://doi.org/10.1016/j.polymer.2018.08.054

Simanke AG, Azeredo AP, Lemos C, Mauler RS (2016) Influence of nucleating agent on the crystallization kinetics and morphology of polypropylene. Polímeros 26(2):152–160. https://doi.org/10.1590/0104-1428.2053

Meng X, Tong C, Xin Z, Gong W, Shi Y, Chen W, Sheng Y (2019) Promotion of zeolite as dispersion support for properties improvement of α nucleating agent in polypropylene. J Polym Res 26(105). https://doi.org/10.1007/s10965-019-1757-x

Kristiansen M, Werner M, Tervoort T, Smith P, Blomenhofer M, Schmidt HW (2003) The binary system isotactic polypropylene/Bis(3,4-dimethylbenzylidene)sorbitol: phase behavior, nucleation, and optical properties. Macromolecules 36(14):5150–5156. https://doi.org/10.1021/ma030146t

Wilder EA, Spontak RJ, Hall CK (2003) The molecular structure and intermolecular interactions of 1,3:2,4-dibenzylidene-D-sorbitol. Mol Phys 101(19):3017–3027. https://doi.org/10.1080/00268970310001597327

Wang G, Zhou Y, Wang S, Chen J, Zhang X, Lu S (2013) Cylindritic structures of isotactic polypropylene molded by sequential co-injection molding. J Polym Res 20(212). https://doi.org/10.1007/s10965-013-0212-7

Wang W, Zhao G, Guan Y, Wu X, Hui Y (2015) Effect of rapid heating cycle injection mold temperature on crystal structures, morphology of polypropylene and surface quality of plastic parts. J Polym Res 22(84). https://doi.org/10.1007/s10965-015-0731-5

Bernland K, Goossens JGP, Smith P, Tervoort TA (2016) On clarification of haze in polypropylene. J Polym Sci B Polym Phys 54(9):865–874. https://doi.org/10.1002/polb.23992

Kobayashi T, Hashimoto T (2005) Development of self-assembling Nucleators for highly transparent semi-crystalline polypropylene. B Chem Soc Jpn 78(2):218–235. https://doi.org/10.1246/bcsj.78.218

Bernland K, Tervoort T, Smith P (2009) Phase behavior and optical-and mechanical properties of the binary system isotactic polypropylene and the nucleating/clarifying agent 1, 2, 3-trideoxy-4, 6: 5, 7-bis-O-[(4-propylphenyl) methylene]-nonitol. Polymer 50(11):2460–2464. https://doi.org/10.1016/j.polymer.2009.03.010

Schawe JEK, Budde F, Alig I (2019) Non-isothermal crystallization of polypropylene with sorbitol-type nucleating agents at cooling rates used in processing. Polym Int 68(2):240–247. https://doi.org/10.1002/pi.5581

Tenma M, Yamaguchi M (2007) Structure and properties of injection-molded polypropylene with sorbitol-based clarifier. Polym Eng Sci 47(9):1441–1446. https://doi.org/10.1002/pen.20839

Tenma M, Mieda N, Takamatsu S, Yamaguchi M (2007) Structure and properties for transparent polypropylene containing sorbitol-based clarifier. J Polym Sci B Polym Phys 46(1):41–47. https://doi.org/10.1002/polb.21340

Nogales A, Mitchell GR, Vaughan AS (2003) Anisotropic crystallization in polypropylene induced by deformation of a nucleating agent network. Macromolecules 36(13):4898–4906. https://doi.org/10.1021/ma0343028

Horváth Z, Gyarmati B, Menyhárd A, Doshev P, Gahleitner M (2014) The role of solubility and critical temperatures for the efficiency of sorbitol clarifiers in polypropylene. RSC Adv 4(38):19737–19745. https://doi.org/10.1039/C4RA01917B

Mahendra IP, Wirjosentono B, Tamrin, Ismail H, Mendez JA, Causinet V (2019) The influence of maleic anhydride-grafted polymers as compatibilizer on the properties of polypropylene and cyclic natural rubber blends. J Polym Res 26(215). https://doi.org/10.1007/s10965-019-1878-2

Othman NAF, Selambakkannu S, Ting TM, Hashim A, Abdullah TAT (2019) Integration of phosphoric acid onto radiation grafted poly (2,3-epoxypropyl methacrylate)-PP/PE non-woven fabrics aimed copper adsorbent via response surface method. J Polym Res 26(283). https://doi.org/10.1007/s10965-019-1963-6

Lai WC, Tseng SJ, Huang PH (2015) Self-assembled structures of 1,3:2,4-di(3,4-dimethylbenzylidene) sorbitol in hydrophobic polymer matrices prepared using different heat treatments. J Nanopart Res 17(11). doi:https://doi.org/10.1007/s11051-015-3267-z

Martin CP, Vaughan AS, Sutton SJ, Swingler SG (2002) Crystallization behavior of a propylene/ethylene copolymer: nucleation and a clarifying additive. J Polym Sci B Polym Phys 40(19):2178–2189. https://doi.org/10.1002/polb.10271

Menyhárd A, Gahleitner M, Varga J, Bernreitner K, Jääskeläinen P, Øysæd H, Pukánszky B (2009) The influence of nucleus density on optical properties in nucleated isotactic polypropylene. Eur Polym J 45(11):3138–3148. https://doi.org/10.1016/j.eurpolymj.2009.08.006

Libster D, Aserin A, Garti N (2007) Advanced nucleating agents for polypropylene. Polym Advan Technol 18(9):685–695. https://doi.org/10.1002/pat.970

Wittmann JC, Lotz B (1990) Epitaxial crystallization of polymers on organic and polymeric substrates. Prog Polym Sci 15(6):909–948. https://doi.org/10.1016/0079-6700(90)90025-v

Lai WC, Lee YC (2016) Self-assembly behavior of gels composed of dibenzylidene sorbitol derivatives and poly(ethylene glycol). RSC Adv 6(100):98042–98051. https://doi.org/10.1039/c6ra18230e

Barkoula NM, Garkhail SK, Peijs T (2009) Effect of compounding and injection molding on the mechanical properties of flax Fiber polypropylene composites. J Reinf Plast Comp 29(9):1366–1385. https://doi.org/10.1177/0731684409104465

Ma Z, Balzano L, Peters GWM (2012) Pressure quench of flow-induced crystallization precursors. Macromolecules 45(10):4216–4224. https://doi.org/10.1021/ma2027325

Guevara-Morales A, Figueroa-López U (2014) Residual stresses in injection molded products. J Mater Sci 49(13):4399–4415. https://doi.org/10.1007/s10853-014-8170-y

Xu T, Lei H, Xie C (2003) The effect of nucleating agent on the crystalline morphology of polypropylene (PP). Mater Des 24(3):227–230. https://doi.org/10.1016/s0261-3069(02)00129-2

Marco C, Ellis G, Gómez MA, Arribas JM (2003) Analysis of the isothermal crystallization of isotactic polypropylene nucleated with sorbitol derivatives. J Appl Polym Sci 88(9):2261–2274. https://doi.org/10.1002/app.11935

Feng Y, Jin X, Hay JN (1998) Effect of nucleating agent addition on crystallization of isotactic polypropylene. J Appl Polym Sci 69(10):2089–2095. https://doi.org/10.1002/(sici)1097-4628(19980906)69:10<2089::aid-app20>3.0.co;2-w

Khanna YP (1993) Rheological mechanism and overview of nucleated crystallization kinetics. Macromolecules 26(14):3639–3643. https://doi.org/10.1021/ma00066a024

Yu W, Wang L, Shi J (2018) Influence of drawing and annealing on the crystallization, viscoelasticity, and mechanical properties for middle-molecular-weight polyethylene fishing monofilaments. Fiber Polym 19(5):1050–1056. https://doi.org/10.1007/s12221-018-7610-8

Men Y, Strobl G (2002) Evidence for a mechanically active high temperature relaxation process in syndiotactic polypropylene. Polymer 43(9):2761–2768. https://doi.org/10.1016/s0032-3861(02)00082-4

Hoyos M, Tiemblo P, Gómez-Elvira JM (2007) The role of microstructure, molar mass and morphology on local relaxations in isotactic polypropylene. The α relaxation. Polymer 48(1):183–194. https://doi.org/10.1016/j.polymer.2006.11.034

Drozdov AD, Claville Christiansen J (2002) The effect of annealing on the time-dependent behavior of isotactic polypropylene at finite strains. Polymer 43(17):4745–4761. https://doi.org/10.1016/s0032-3861(02)00315-4

Paul SA, Sinturel C, Joseph K, Mathew GDG, Pothan LA, Thomas S (2009) Dynamic mechanical analysis of novel composites from commingled polypropylene fiber and banana fiber. Polym Eng Sci 50(2):384–395. https://doi.org/10.1002/pen.21522

Sanadi AR, Caulfield DF (2000) Transcrystalline interphases in natural fiber-PP composites: effect of coupling agent. Compos Interface 7(1):31–43. https://doi.org/10.1163/156855400300183560

Caveda S, Pérez E, Blázquez-Blázquez E, Peña B, van Grieken R, Suárez I, Benavente R (2017) Influence of structure on the properties of polypropylene copolymers and terpolymers. Polym Test 62:23–32. https://doi.org/10.1016/j.polymertesting.2017.06.008

Housmans JW, Steenbakkers RJA, Roozemond PC, Peters GWM, Meijer HEH (2009) Saturation of Pointlike nuclei and the transition to oriented structures in flow-induced crystallization of isotactic polypropylene. Macromolecules 42(15):5728–5740. https://doi.org/10.1021/ma802479c

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51563015), the Innovation and Entrepreneurship Talent Project of Lanzhou (2019-RC-53), and the Innovation Foundation of China National Petroleum Corporation (2019D-5007-0408).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Liu, X., Li, Y. et al. Nanoengineering of transparent polypropylene containing sorbitol-based clarifier. J Polym Res 27, 198 (2020). https://doi.org/10.1007/s10965-020-02169-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02169-3