Abstract

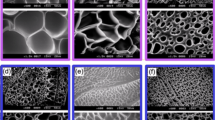

Skin tissue regeneration scaffolds represent a promising field of research focused on formulation and optimization of cost-effective extracellular matrix based on natural polymers. Sodium carboxymethylcellulose is one of the most widely studied and least expensive natural polymers for fabricating film formulations aiding in skin tissue regeneration process the following damage, but its hydrophilicity contributes to its failure to prevent loss of excessive moisture from wound, low adsorb-ability, less mechanical strength, and rapid erosion. This study aims to develop a surfactant modified sodium carboxymethylcellulose-based films addressing the needs for skin wound healing applications. Sodium carboxymethylcellulose films were developed with varying concentrations of tween 80 in the range of 0.05 to 0.5% w/w and subjected to various physicochemical characterization tests like adsorption, moisture uptake, erosion, water vapor transmission, and water vapor permeability rate, vibrational, thermal and morphological analysis. The results indicated that the formulation containing 0.3% w/w of tween 80 was able to form films with a significant-good adsorb-ability, reduced percent erosion and high tensile strength with the formation of “folds” in the film surface. The vibrational and thermal analysis revealed fluidization of hydrophilic as well as hydrophobic domains which was attributed to the development of new “bonding” between the polymer and surfactant and/or plasticizer moieties in the formulation which though didn’t affect the transition temperature but significantly reduced the energy to induce transition which is envisaged to increase the elasticity of the film. This optimized combination of polymer and tween 80 may play an effective role in hastening skin regeneration process following damage. Sodium carboxymethylcellulose films with added 0.3% w/w tween 80 represent an ideal combination for the fabrication of sodium carboxymethylcellulose.

Similar content being viewed by others

References

Cho DID, Yoo HJ (2015) Microfabrication methods for biodegradable polymeric carriers for drug delivery system applications: a review. J Microelectromech Syst 24:10–18. https://doi.org/10.1109/JMEMS.2014.2368071

Chiang YT, Lo CL (2014) pH-responsive polymer-liposomes for intracellular drug delivery and tumor extracellular matrix switched-on targeted cancer therapy. Biomaterials 35:5414–5424. https://doi.org/10.1016/j.biomaterials.2014.03.046

Jo C, Kang H, Lee NY et al (2005) Pectin- and gelatin-based film: effect of gamma irradiation on the mechanical properties and biodegradation. Radiat Phys Chem 72:745–750. https://doi.org/10.1016/j.radphyschem.2004.05.045

Sanad RAB, Abdel-Bar HM (2017) Chitosan–hyaluronic acid composite sponge scaffold enriched with Andrographolide-loaded lipid nanoparticles for enhanced wound healing. Carbohydr Polym 173:441–450. https://doi.org/10.1016/j.carbpol.2017.05.098

Bohl Masters KS, Leibovich SJ, Belem P et al (2002) Effects of nitric oxide releasing poly(vinyl alcohol) hydrogel dressings on dermal wound healing in diabetic mice. Wound Repair Regen 10:286–294. https://doi.org/10.1046/j.1524-475X.2002.10503.x

Chen JP, Chang GY, Chen JK (2008) Electrospun collagen/chitosan nanofibrous membrane as wound dressing. Colloids Surfaces A Physicochem Eng Asp 313–314:183–188. https://doi.org/10.1016/j.colsurfa.2007.04.129

Mohammadi MR, Rabbani S, Bahrami SH et al (2016) Antibacterial performance and in vivo diabetic wound healing of curcumin loaded gum tragacanth/poly(ε-caprolactone) electrospun nanofibers. Mater Sci Eng C 69:1183–1191. https://doi.org/10.1016/j.msec.2016.08.032

Paunonen S (2013) Strength and barrier enhancements of cellophane and cellulose derivative films: a review. BioResources 8:3098–3121. https://doi.org/10.15376/biores.8.2.3098-3121

Park KH, Han SH, Hong JP, Han SK, Lee DH, Kim BS, Ahn JH, Lee JW (2018) Topical epidermal growth factor spray for the treatment of chronic diabetic foot ulcers: a phase III multicenter, double-blind, randomized, placebo-controlled trial. Diabetes Res Clin Pract 142:335–344. https://doi.org/10.1016/j.diabres.2018.06.002

Jeong KH, Park D, Lee YC (2017) Polymer-based hydrogel scaffolds for skin tissue engineering applications: a mini-review. J Polym Res 24

Tharanathan RN (2003) Biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol 14:71–78. https://doi.org/10.1016/S0924-2244(02)00280-7

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286:1173–1180. https://doi.org/10.1007/s00396-008-1882-2

Kelessidis VC, Poulakakis E, Chatzistamou V (2011) Use of Carbopol 980 and carboxymethyl cellulose polymers as rheology modifiers of sodium-bentonite water dispersions. Appl Clay Sci 54:63–69. https://doi.org/10.1016/j.clay.2011.07.013

Oun AA, Rhim JW (2015) Preparation and characterization of sodium carboxymethyl cellulose/cotton linter cellulose nanofibril composite films. Carbohydr Polym 127:101–109. https://doi.org/10.1016/j.carbpol.2015.03.073

Rowe R, Sheskey P, Quinn M (2009) Handbook of pharmaceutical excipients

Sweeney IR, Miraftab M, Collyer G (2012) A critical review of modern and emerging absorbent dressings used to treat exuding wounds. Int Wound J 9:601–612. https://doi.org/10.1111/j.1742-481X.2011.00923.x

Garrett Q, Simmons PA, Xu S et al (2007) Carboxymethylcellulose binds to human corneal epithelial cells and is a modulator of corneal epithelial wound healing. Investig Opthalmology Vis Sci 48:1559. https://doi.org/10.1167/iovs.06-0848

Jones V, Grey J, Harding K (2006) ABC of wound healing. Wound dressings. Br Med J 332:777–780. https://doi.org/10.1136/bmj.332.7544.777

Bifani V, Ramírez C, Ihl M et al (2007) Effects of murta (Ugni molinae Turcz) extract on gas and water vapor permeability of carboxymethylcellulose-based edible films. LWT - Food Sci Technol 40:1473–1481. https://doi.org/10.1016/j.lwt.2006.03.011

Zhong SP, Zhang YZ, Lim CT (2010) Tissue scaffolds for skin wound healing and dermal reconstruction. Wiley Interdiscip Rev Nanomedicine Nanobiotechnology 2:510–525. https://doi.org/10.1002/wnan.100

Mano JF, Silva GA, Azevedo HS et al (2007) Natural origin biodegradable systems in tissue engineering and regenerative medicine: present status and some moving trends. J R Soc Interface

Yadav M, Rhee KY, Jung IH, Park SJ (2013) Eco-friendly synthesis , characterization and properties of a sodium carboxymethyl cellulose / graphene oxide nanocomposite film:687–698. https://doi.org/10.1007/s10570-012-9855-5

Rippon M, White R, Davies P (2007). Skin adhesives and their role in wound dressings:3

Martelli SM, Motta C, Caon T et al (2017) Edible carboxymethyl cellulose films containing natural antioxidant and surfactants: α-tocopherol stability, in vitro release and film properties. LWT - Food Sci Technol 77:21–29. https://doi.org/10.1016/j.lwt.2016.11.026

Han Y, Yu M, Wang L (2018) Physical and antimicrobial properties of sodium alginate/carboxymethyl cellulose films incorporated with cinnamon essential oil. Food Packag Shelf Life 15:35–42. https://doi.org/10.1016/j.fpsl.2017.11.001

Ghanbarzadeh B, Almasi H, Entezami AA (2010) Physical properties of edible modified starch/carboxymethyl cellulose films. Innov Food Sci Emerg Technol 11:697–702. https://doi.org/10.1016/j.ifset.2010.06.001

Ghanbarzadeh B, Almasi H (2011) International journal of biological macromolecules physical properties of edible emulsified films based on carboxymethyl cellulose and oleic acid. Int J Biol Macromol 48:44–49. https://doi.org/10.1016/j.ijbiomac.2010.09.014

Rodríguez M, Osés J, Ziani K, Maté JI (2006) Combined effect of plasticizers and surfactants on the physical properties of starch based edible films. Food Res Int 39:840–846. https://doi.org/10.1016/j.foodres.2006.04.002

Ziani K, Oses J, Coma V, Maté JI (2008) Effect of the presence of glycerol and tween 20 on the chemical and physical properties of films based on chitosan with different degree of deacetylation. LWT - Food Sci Technol 41:2159–2165. https://doi.org/10.1016/j.lwt.2007.11.023

Rachtanapun P (2009) Blended films of Carboxymethyl cellulose from papaya Peel ( CMCp ) and corn starch 266:259–266

Farzanian K, Ghahremaninezhad A (2018) On the effect of chemical composition on the desorption of superabsorbent hydrogels in contact with a porous Cementitious material. Gels 4:1–13. https://doi.org/10.3390/gels4030070

Boateng KH, Metthews HNE, Stevens GME (2008) Wound healing dressings and drug delivery systems: a review. Int J Pharm Technol 5:2764–2786. https://doi.org/10.1002/jps.21210

Andreuccetti C, Carvalho RA, Galicia-garcía T et al (2011) Gelatin-based edible films.Pdf. J. Food Eng 103:129–136

Villalobos R, Hernández-Muñoz P, Chiralt A (2006) Effect of surfactants on water sorption and barrier properties of hydroxypropyl methylcellulose films. Food Hydrocoll 20:502–509. https://doi.org/10.1016/j.foodhyd.2005.04.006

Habash M, Reid G (1999) Microbial biofilms: their development and significance for medical device-related infections. J Clin Pharmacol 39:887–898

Wong TW, Ramli NA (2014) Carboxymethylcellulose film for bacterial wound infection control and healing. Carbohydr Polym 112:367–375

Ortega-toro R, Jiménez A, Talens P, Chiralt A (2014) Food hydrocolloids effect of the incorporation of surfactants on the physical properties of corn starch fi lms. Food Hydrocoll 38:66–75. https://doi.org/10.1016/j.foodhyd.2013.11.011

Apel PY, Blonskaya IV, Dmitriev SN et al (2007). Fabrication of nanopores in polymer foils with surfactant-controlled longitudinal profiles:305302. https://doi.org/10.1088/0957-4484/18/30/305302

Nga NK, Giang LT, Huy TQ et al (2013) Surfactant-assisted size control of hydroxyapatite nanorods for bone tissue engineering. Colloids surfaces B biointerfaces:1–8. https://doi.org/10.1016/j.colsurfb.2013.11.001

Kimmel HM, Grant A, Ditata J (2016) The presence of oxygen in wound healing. Wounds 28:264–270

Ose J, Ziani K, Mate JI, Rodrı M (2006) Combined effect of plasticizers and surfactants on the physical properties of starch based edible films 39:840–846. https://doi.org/10.1016/j.foodres.2006.04.002

Basu P (2018) Characterization and evaluation of Carboxymethyl cellulose-based films for healing of full-thickness wounds in Normal and diabetic rats. ACS Omega 3:12622–12632. https://doi.org/10.1021/acsomega.8b02015

Lui YS (2012) Sustained-release of naproxen sodium from electrospun-aligned PLLA-PCL scaffolds. J Tissue Eng Regen Med 6:135–143

Tong Q, Xiao Q, Lim LT (2008) Preparation and properties of pullulan-alginate-carboxymethylcellulose blend films. Food Res Int 41:1007–1014. https://doi.org/10.1016/j.foodres.2008.08.005

Saurabh CK, Gupta S, Variyar PS, Sharma A (2016) Effect of addition of nanoclay, beeswax, tween-80 and glycerol on physicochemical properties of guar gum films. Ind Crop Prod 89:109–118. https://doi.org/10.1016/j.indcrop.2016.05.003

Ballesteros LF, Cerqueira MA, Teixeira JA, Mussatto SI (2018) Production and physicochemical properties of carboxymethyl cellulose films enriched with spent coffee grounds polysaccharides. International Journal of Biological Macromolecules 106:647–655

Amim J, Leandro J, Petri DFS (2012) Effect of sorbitan-based surfactants on glass transition temperature of cellulose esters. J Therm Anal Calorim 107:1259–1265

Andreuccetti C, Carvalho RA, Galicia-García T et al (2011) Effect of surfactants on the functional properties of gelatin-based edible films. J Food Eng 103:129–136. https://doi.org/10.1016/j.jfoodeng.2010.10.007

dos Santos SA, Rodrigues BVM, Oliveira FC et al (2019) Characterization and in vitro and in vivo assessment of poly(butylene adipate-co-terephthalate)/nano-hydroxyapatite composites as scaffolds for bone tissue engineering. J Polym Res 26:1–11. https://doi.org/10.1007/s10965-019-1706-8

Mollah MZI, Akter N, Quader FB et al (2016) Biodegradable colour polymeric film (starch-chitosan) development: characterization for packaging materials. Open J Org Polym Mater 06:11–24

Acknowledgments

The authors acknowledged the Gomal University DIKhan and Higher Education Commission of Pakistan for financial and facility support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest and all authors confirm agreement with the final statement.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, M., Khan, N.R., Basit, H.M. et al. Physico-chemical based mechanistic insight into surfactant modulated sodium Carboxymethylcellulose film for skin tissue regeneration applications. J Polym Res 27, 20 (2020). https://doi.org/10.1007/s10965-019-1987-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1987-y