Abstract

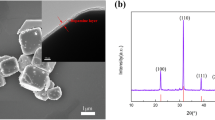

Dielectric polymer composites with high breakdown strength and discharged energy density have potential applications in modern electric power systems. In this study, composites comprising MWCNTs-TiO2 core-shell nanoparticles and poly(vinylidene fluoride) (PVDF) were fabricated by a solution casting method, followed by a melting and quenching process. The obtained composites are γ-phase PVDF dominated and present a dense structure. By the incorporation of MWCNTs-TiO2 core-shell nanoparticles, the dielectric constant of composites can be significantly enhanced while the dielectric loss of composites remains low. Because of the core-shell structure of well-dispersed MWCNTs-TiO2 and their strong interactions with matrix, high breakdown strength above 175 V/μm can be achieved in the composites. Additionally, the composites exhibit enhanced discharged energy density, which can be as high as 6.4 J/cm3 at 250 V/μm, while the maximum discharged energy density obtained in pure PVDF is only 2.6 J/cm3 (270 V/μm).

Similar content being viewed by others

References

Hu PH, Shen Y, Guan YH (2014) Adv Mater 24:3172–3178

Li Z, Fredin LA, Tewari P (2010) Chem Mater 22:5154–5164

Chu BJ, Zhou X, Ren KL (2006) Science 313:334–336

Luo SB, Yu SH, Sun R, Wong CP (2014) ACS Appl Mater Interfaces 6:176–182

Dang ZM, Wang HY, Xu HP (2009) Appl Phys Lett 89:112902-112902-3

Gao L, He JL, Hu J, Li Y (2014) J Phys Chem C 118:831–838

Lund A, Gustafsson C, Bertilsson H, Rychwalski RW (2011) Compos Sci Technol 71:222–229

He F, Lau S, Chan HL, Fan JT (2009) Adv Mater 21:710–715

Dang ZM, Lin YH, Nan CW (2003) Adv Mater 15:1625–1629

Spitalsky Z, Tasis D, Papagelis K, Galiotis (2010) Prog Polym Sci 35:357–401

Shafee E, Gamal M, Isa M (2012) J Polym Res 19:1–8

Zhang SH, Zhang NY, Huang C, Ren KL, Zhang QM (2005) Adv Mater 17:1897–1901

Wang Q, Zhu L (2011) J Polym Sci B: Polym Phys 49:1421–1429

Zhang WJ, Zhou Z, Li QF, Chen GX (2014) Ind Eng Chem Res 53:6699–6707

Qiang ZX, Liang GZ, Gu AJ, Yuan L (2014) Ind Eng Chem Res 53:4726–4731

Yang C, Lin YH, Nan CW (2009) Carbon 47:1096–1101

Huang X, Feng M, Liu XB (2014) RSC Adv 4:4985–4992

Wu C, Huang XY, Wu XF, Yu JH, Xie LY, Jiang PK (2012) Compos Sci Technol 72:521–527

Feng Y, Li LW, Wang JP, Yin JH, Fei WD (2015) J Mater Chem A 3:20313–20321

Zhang ZC, Gu YZ, Bi JY, Wang SK, Li M, Zhang ZG (2015) Mater Lett 160:16–19

Liu ZD, Feng Y, Li LW (2015) RSC Adv 5:29017–29021

Huang XY, Jiang PK (2015) Adv Mater 27:546–554

Dang ZM, Yuan JK, Zha JW, Zhou T, Li ST, Hu GH (2012) Prog Mater Sci 57:660–723

Zhang L, Yuan H, Chen G, Wang DR, Han BZ, Dang ZM (2015) Compos Sci Technol 110:126–131

Yang L, Qiu JH, Ji HL, Zhu KJ, Wang J (2014) J Mater Sci Mater Electron 25:2126–2137

Ning NY, Bai X, Yang D (2014) RSC Adv 4:4543–4551

Yang L, Qiu JH, Ji HL, Zhu KJ, Wang J (2014) Compos A: Appl Sci Manuf 65:125–134

Martins P, Lopes AC, Lanceros-Mendez S (2014) Prog Polym Sci 39:683–706

Gomes J, Nunes JS, Sencadas V, Lanceros-Mendez S (2010) Smart Mater Struct 19:065010

Li L, Zhang MQ, Rong MZ, Ruan WH (2014) RSC Adv 4:3938–3943

Alamusi, Xue JM, Wu LK (2014) Nanoscale 4:7250–7255

Tang HX, Sodano HA (2013) Appl Phys Lett 102:063901

Li WJ, Meng QJ, Zheng YS, Zhang ZC, Xia WM, Xu Z (2010) Appl Phys Lett 96:192905

Martin CA, Sandler JKW, Shaffer MSP (2004) Compos Sci Technol 64:2309–2316

Suherman H, Sulong AB, Sahari J (2010) Int J Mech Mater Eng 5:74–79

Imamura R, Silva AB, Gregorio R Jr (2008) J Appl Polym Sci 110:3242–3246

Tiwari V, Srivastava (2014) J Polym Res 21:1–8

Gregorio R Jr (2006) J Appl Polym Sci 100:3272–3279

Gasparini TM, Bretas RES, Silva AB, Gregorio R Jr (2012) J Polym Sci: B: Polym Phys 50:1304–1311

Javadi A, Xiao YL, Xu WJ, Gong SQ (2012) J Mater Chem 22:830–834

Chanmal CV, Jog JP (2008) Express Polym Lett 2:294–301

Yu K, Wang H, Zhou YC, Bai YY, Niu YJ (2013) J Appl Phys 113:034105

Wen F, Xu Z, Xia WM, Wei XY, Zhang ZC (2013) Polym Eng Sci 53:897–904

Fang LJ, Wu C, Qian R (2014) RSC Adv 4:21010–21017

Xie LY, Huang XY, Li BW (2013) Phys Chem Chem Phys 15:17560–17569

Huang XY, Xie LY, Yang K (2014) IEEE Trans Dielectr Electr Insul 21:480–487

Guo N, Dibenedetto SA, Tewari P (2010) Chem Mater 22:1567–1578

Luo BC, Wang XH, Wang YP, Li LT (2014) J Mater Chem A 2:510–519

Acknowledgments

This work was supported by the Major State Basic Research Development Program of China (973 Program, Grant No National. 2015CB057501), Fundamental Research Funds for the Central Universities (NE2015101& NE2015001). It is also partially supported by the Research Fund of State Key Laboratory of Mechanical Structures (No.0515Y02) and Priority Academic Program Development of Jiangsu Higher Education Instituations (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Qiu, J., Ji, H. et al. MWCNTs-TiO2 core-shell nanoassemblies for fabrication of poly(vinylidene fluoride) based composites with high breakdown strength and discharged energy density. J Polym Res 23, 65 (2016). https://doi.org/10.1007/s10965-016-0951-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-0951-3