Abstract

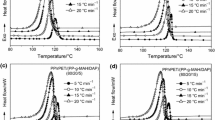

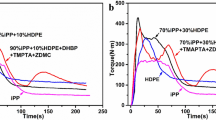

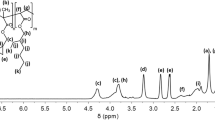

Bi-functional co-agent, diallyl phthalate (DAP), −assisted melting free-radical grafting of maleic anhydride (MAH) on polypropylene (PP) is carried out by reactive extrusion. The PP/recycled polyethylene terephthalate (rPET) blends with and without PP-g-MAH/DAP (PP grafted with both MAH and DAP) are conducted on a twin-screw extruder. It reveals that the introduction of DAP can significantly enhance the grafting degree of MAH and decrease the chain scission of PP. The maximum extent of MAH grafting (1.5 wt.%) is obtained when DCP and MAH contents are 0.5 and 6.0 wt.%, respectively, and the DAP/MAH molar ratio is 0.3. Besides, differential scanning calorimetry (DSC) analysis shows that the crystallization temperature of grafted PP is higher than that of pure PP due to the nucleation of grafted groups. Fourier transform infrared spectroscopy (FTIR) analysis proves that chemical reactions take place between PP-g-MAH/DAP and rPET. In particular, scanning electron microscopy (SEM) observations demonstrate that, the PP/rPET blends compatibilized with PP-g-MAH/DAP show enhanced adhesion at the interface comparing with the binary PP/rPET blend, which is also proved by DSC measurements, dynamic mechanical analysis (DMA) and mechanical properties.

Similar content being viewed by others

References

Taepaiboon P, Junkasem J, Dangtungee R, Amornsakchai T, Supaphol P (2006) In situ microfibrillar‐reinforced composites of isotactic polypropylene/recycled poly (ethylene terephthalate) system and effect of compatibilizer. J Appl Polym Sci 102(2):1173–1181

Pracella M, Rolla L, Chionna D, Galeski A (2002) Compatibilization and properties of poly (ethylene terephthalate)/polyethylene blends based on recycled materials. Macromol Chem Phys 203(10–11):1473–1485

Oromiehie A, Mamizadeh A (2004) Recycling PET beverage bottles and improving properties. Polym Int 53(6):728–732

Tao Y, Mai K (2007) Non-isothermal crystallization and melting behavior of compatibilized polypropylene/recycled poly (ethylene terephthalate) blends. Eur Polym J 43(8):3538–3549

Tao Y, Pan Y, Zhang Z, Mai K (2008) Non-isothermal crystallization, melting behavior and polymorphism of polypropylene in β-nucleated polypropylene/recycled poly (ethylene terephthalate) blends. Eur Polym J 44(4):1165–1174

Lin Z, Shen J, Chen C, Zhang X (2011) Polypropylene/wasted poly (ethylene terephthalate) fabric composites compatibilized by two different methods: crystallization and melting behavior, crystallization morphology, and kinetics. J Appl Polym Sci 121(4):1972–1981

Bettini SH, de Mello LC, Munoz PA, Ruvolo Filho A (2013) Grafting of maleic anhydride onto polypropylene, in the presence and absence of styrene, for compatibilization of poly (ethylene terephthalate)/(ethylene–propylene) blends. J Appl Polym Sci 127(2):1001–1009

Friedrich K, Evstatiev M, Fakirov S, Evstatiev O, Ishii M, Harrass M (2005) Microfibrillar reinforced composites from PET/PP blends: processing, morphology and mechanical properties. Compos Sci Technol 65(1):107–116

Oyman Z, Tincer T (2003) Melt blending of poly (ethylene terephthalate) with polypropylene in the presence of silane coupling agent. J Appl Polym Sci 89(4):1039–1048

Sombatdee S, Amornsakchai T, Saikrasun S (2012) Reinforcing performance of recycled PET microfibrils in comparison with liquid crystalline polymer for polypropylene based composite fibers. J Polym Res 19(3):1–13

Atta A, Abdel-Rauf M, Maysour N, Abdul-Rahiem AM, Abdel-Azim A-A (2006) Surfactants from recycled poly (ethylene terephthalate) waste as water based Oil spill dispersants. J Polym Res 13(1):39–52

Saikrasun S, Limpisawasdi P, Amornsakchai T (2009) Comparative study on phase and properties between rPET/PS and LCP/PS in situ microfibrillar-reinforced composites. J Polym Res 16(4):443–454

Liu S, Zhou L, Li L, Yu S, Liu F, Xie C, Song Z (2013) Isooctanol alcoholysis of waste polyethylene terephthalate in acidic ionic liquid. J Polym Res 20(12):1–6

Asgari M, Masoomi M (2012) Thermal and impact study of PP/PET fibre composites compatibilized with glycidyl methacrylate and maleic anhydride. Compos Part B: Eng 43(3):1164–1170

Si X, Guo L, Wang Y, K-t L (2008) Preparation and study of polypropylene/polyethylene terephthalate composite fibres. Compos Sci Technol 68(14):2943–2947

Jayanarayanan K, Thomas S, Joseph K (2008) Morphology, static and dynamic mechanical properties of in situ microfibrillar composites based on polypropylene/poly (ethylene terephthalate) blends. Compos Part A: Appl Sci 39(2):164–175

Chiu H-T, Hsiao Y-K (2006) Compatibilization of poly (ethylene terephthalate)/polypropylene blends with maleic anhydride grafted polyethylene-octene elastomer. J Polym Res 13(2):153–160

Pracella M, Chionna D (2003) Reactive compatibilization of blends of PET and PP modified by GMA grafting. Macromol Symp 198(1):161–172

Bae TY, Park KY, Kim DH, Suh KD (2001) Poly (ethylene terephthalate)/polypropylene reactive blends through isocyanate functional group. J Appl Polym Sci 81(5):1056–1062

Papadopoulou C, Kalfoglou N (2000) Comparison of compatibilizer effectiveness for PET/PP blends: their mechanical, thermal and morphology characterization. Polymer 41(7):2543–2555

Pang Y, Jia D, Hu H, Hourston D, Song M (2000) Effects of a compatibilizing agent on the morphology, interface and mechanical behaviour of polypropylene/poly (ethylene terephthalate) blends. Polymer 41(1):357–365

Yoon KH, Lee HW, Park OO (1998) Properties of poly(ethylene terephthalate) and maleic anhydride-grafted polypropylene blends by reactive processing. J Appl Polym Sci 70(2):389–395

Heino M, Kirjava J, Hietaoja P (1997) Compatibilization of polyethylene terephthalate/polypropylene blends with styrene–ethylene/butylene–styrene (SEBS) block copolymers. J Appl Polym Sci 65(2):241–249

Calcagno CI, Mariani CM, Teixeira SR, Mauler RS (2009) Morphology and crystallization behavior of the PP/PET nanocomposites. J Appl Polym Sci 111(1):29–36

Shi W, Li Y, Xu J, Ma G, Sheng J (2007) Morphology development in multi‐component polymer blends: I composition effect on phase morphology in PP/PET polymer blends. J Macromol Sci Part B: Phys 46(6):1115–1126

Akbari M, Zadhoush A, Haghighat M (2007) PET/PP blending by using PP-g-MA synthesized by solid phase. J Appl Polym Sci 104(6):3986–3993

Saujanya C, Radhakrishnan S (2001) Structure development and properties of PET fibre filled PP composites. Polymer 42(10):4537–4548

Li Y, Xie XM, Guo BH (2001) Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 42(8):3419–3425

Bettini S, Ruvolo Filho A (2008) Styrene‐assisted grafting of maleic anhydride onto polypropylene by reactive processing. J Appl Polym Sci 107(3):1430–1438

Henry GR, Drooghaag X, Rousseaux DD, Sclavons M, Devaux J, Marchand Brynaert J, Carlier V (2008) A practical way of grafting maleic anhydride onto polypropylene providing high anhydride contents without sacrificing excessive molar mass. J Polym Sci, Part A: Polym Chem 46(9):2936–2947

Drooghaag X, Rousseaux DDJ, Henry GRP, Sclavons M, Carlier V, Marchand-Brynaert J (2010) Mediated melt functionalization of polypropylene. Polym Degrad Stab 95(3):342–345

Augier S, Coiai S, Gragnoli T, Passaglia E, Pradel JL, Flat JJ (2006) Coagent assisted polypropylene radical functionalization: monomer grafting modulation and molecular weight conservation. Polymer 47(15):5243–5252

Coiai S, Passaglia E, Aglietto M, Ciardelli F (2004) Control of degradation reactions during radical functionalization of polypropylene in the melt. Macromolecules 37(22):8414–8423

Coiai S, Augier S, Pinzino C, Passaglia E (2010) Control of degradation of polypropylene during its radical functionalisation with furan and thiophene derivatives. Polym Degrad Stab 95(3):298–305

Zhu L, Tang G, Shi Q, Cai C, Yin J (2006) Neodymium oxide-assisted melt free-radical grafting of maleic anhydride on isotactic-polypropylene by reactive extrusion. J Polym Sci, Part B: Polym Phys 44(1):134–142

Ni QL, Fan JQ, Niu H, Dong JY (2011) Enhancement of graft yield and control of degradation during polypropylene maleation in the presence of polyfunctional monomer. J Appl Polym Sci 121(5):2512–2517

Sengupta SS, Parent JS, Chaudhary BI (2009) Selectivity of allylic coagent‐mediated polypropylene maleation. Polym Eng Sci 49(10):1945–1950

Jayanarayanan K, Bhagawan SS, Thomas S, Joseph K (2007) Morphology development and non isothermal crystallization behaviour of drawn blends and microfibrillar composites from PP and PET. Polym Bull 60(4):525–532

De Roover B, Sclavons M, Carlier V, Devaux J, Legras R, Momtaz A (1995) Molecular characterization of maleic anhydride‐functionalized polypropylene. J Polym Sci, Part A: Polym Chem 33(5):829–842

Lei C, Li S, Chen D, Wu B, Huang W (2011) Melt grafting of maleic anhydride onto polypropylene with 1-decene as a second monomer. J Appl Polym Sci 119(1):102–110

Shi D, Hu GH, Li R (2006) Concept of nano-reactor for the control of the selectivity of the free radical grafting of maleic anhydride onto polypropylene in the melt. Chem Eng Sci 61(11):3780–3784

Simpson W, Holt T, Zetie R (1953) The structure of branched polymers of diallyl phthalate. J Polym Sci 10(5):489–498

Seo Y, Kim J, Kim KU, Kim YC (2000) Study of the crystallization behaviors of polypropylene and maleic anhydride grafted polypropylene. Polymer 41(7):2639–2646

Luo W, Liu X, Fu Y (2012) Melt grafting of maleic anhydride onto polypropylene with assistance of α‐methylstyrene. Polym Eng Sci 52(4):814–819

Lepers JC, Favis BD, Tabar RJ (1997) The relative role of coalescence and interfacial tension in controlling dispersed phase size reduction during the compatibilization of polyethylene terephthalate/polypropylene blends. J Polym Sci, Part B: Polym Phys 35(14):2271–2280

Cui YY, Dong BJ, Li BL, Li SC (2013) Properties of polypropylene/poly(ethylene terephthalate) thermostimulative shape memory blends reactively compatibilized by maleic anhydride grafted polyethylene-octene elastomer. Int J Polym Mater 62(13):671–677

Acknowledgments

We gratefully acknowledge the Fundamental Research Funds for the Central University and the financial support of Jiangsu Hanneng Electric Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Y., Liang, C., Bo, Y. et al. Compatibilization of polypropylene/recycled polyethylene terephthalate blends with maleic anhydride grafted polypropylene in the presence of diallyl phthalate. J Polym Res 22, 35 (2015). https://doi.org/10.1007/s10965-014-0591-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-014-0591-4