Abstract

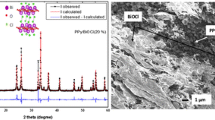

Colloidal graphite-copper phthalocyanine (CG-CuPc) hybrid material was synthesized as a conducting additive to improve the properties of phthalonitrile-terminated polyarylene ether nitriles (PEN-t-ph) polymer composites. These colloidal graphite (CG) was modified with 3-Aminophenoxyphthalonitrile through the catalysis of copper ions by solvothermal processing, which is aimed to increase the adhesion between filler and polymer matrix as well as minimize the interfacial phonon scattering. Scanning electron microscopy (SEM), fourier transform infrared spectroscopy (FTIR), and UV-vis spectroscopy were employed to characterize the as-synthesized CG-CuPc. The results indicated that the CuPc grew successfully on the surface of CG. And the content of CuPc was calculated to be 19.77 wt% with thermal gravimetric analyses (TGA) testing. Subsequently, the hybrid CG-CuPc was introduced to the high-performance PEN-t-ph. Typical SEM images reveal the interface between the filler and surrounding matrix is fuzzy and relatively coherent. As expected, the remarkable enhancement in thermal conductivity of the composites was achieved with flexibility maintained. The thermal conductivity (κ) of sample with 16 wt% CG-CuPc reached the maximum value (0.597 W/(mK)), with a 80 % increase compared to the pure polymer. The TGA curves indicated that all sample showed excellent thermal stabilities with initial degradation temperature (T id ) above 490 °C. Apart from the thermal analysis, the mechanical testing reveals that the tensile strength increased from 79 MPa for pure PEN-t-ph to 86 MPa for PEN-t-ph/CG-CuPc composite with 5 wt% CG-CuPc filler loading.

Similar content being viewed by others

References

Zou YK, Liu XB (2012) Effect of curing behaviors on the properties of poly (arylene ether nitrile) end-capped with phthalonitrile. J Appl Polym Sci 125:3829–3835

Zhan Y, Yang X, Meng F (2011) Viscoelasticity and thermal stability of poly (arylene ether nitrile) composites with various functionalized carbon nanotubes. Polym Int 60:1342–1348

Tang H, Zhong J, Yang J (2011) Flexible polyarylene ether Nitrile/BaTiO3 composites with high energy density for film capacitor applications. J Electron Mater 40:141–148

Tong L, Pu Z, Chen Z, Liu XB (2014) Effect of nanosilica on the thermal, mechanical, and dielectric properties of polyarylene ether nitriles terminated with phthalonitrile. Polym Compos 35:344–350

Shi SL, Zhang LZ, Li JS (2009) Electrical and dielectric properties of multiwall carbon nanotube/polyaniline composites. J Polym Res 16:395–399

Ghaemy M, Soudabe Q, Maasoomeh B (2013) Nanostructured composites of poly (triazole-amide-imide)s and reactive titanium oxide by epoxide functionalization: thermal, mechanical, photophysical and metal ions adsorption properties. J Polym Res 20:1–15

Saleem A, Frormann L, Iqbal A (2007) Mechanical, thermal and electrical resisitivity properties of thermoplastic composites filled with carbon fibers and carbon particles. J Polym Res 14:121–127

Yavari F, Fard HR, Pashayi K (2011) Enhanced thermal conductivity in a nanostructured phase change composite due to low concentration graphene additives. J Phys Chem C 115:8753–8758

Jiang X, Bin Y, Matsuo M (2005) Electrical and mechanical properties of polyimide–carbon nanotubes composites fabricated by in situ polymerization. Polymer 46:7418–7424

Liu MD, Xu M, Tong L, Huang X, Liu XB (2014) Nitrile functionalized Al2O3 reinforced polyarylene ether nitriles terminated with phthalonitrile composites. J Polym Res 21:1–8

Kim KH, Ong JL, Okuno O (2002) The effect of filler loading and morphology on the mechanical properties of contemporary composites. J Prosthet Dent 87:642–649

Xue Y, Liu Y, Lu F (2012) Functionalization of graphene oxide with polyhedral oligomeric silsesquioxane (POSS) for multifunctional applications. J Phys Chem Lett 3:1607–1612

Xiao M, Sun L, Liu J (2002) Synthesis and properties of polystyrene/graphite composites. Polymer 43:2245–2248

Zou JF, Yu ZZ, Pan YX (2002) Conductive mechanism of polymer/graphite conducting composites with low percolation threshold. J Polym Sci Polym Phys 40:954–963

Dailly A, Ghanbaja J, Willmann P (2004) Synthesis, characterization and lithium electrochemical insertion into antimony-based graphite composites. J Power Sources 136:281–284

Yu A, Ramesh P, Sun X (2008) Enhanced thermal conductivity in a hybrid graphite nanoplatelet–carbon nanotube filler for epoxy composites. Adv Mater 20:4740–4744

Krupa I, Novák I, Chodák I (2004) Electrically and thermally conductive polyethylene/graphite composites and their mechanical properties. Synth Met 145:245–252

Yasmin A, Daniel IM (2004) Mechanical and thermal properties of graphite platelet/epoxy composites. Polymer 45:8211–8219

Lu Y, Yin Y, Mayers BT (2002) Modifying the surface properties of superparamagnetic iron oxide nanoparticles through a sol-gel approach. Nano Lett 2:183–186

Lupo F, Kamalakaran R, Scheu C (2004) Microstructural investigations on zirconium oxide–carbon nanotube composites synthesized by hydrothermal crystallization. Carbon 42:1995–1999

Sato K, Horibe H, Shirai T (2010) Thermally conductive composite films of hexagonal boron nitride and polyimide with affinity-enhanced interfaces. J Mater Chem 20:2749–2752

Pukanszky B (1990) Influence of interface interaction on the ultimate tensile properties of polymer composites. Composites 21:255–262

Kim JA, Seong DG, Kang TJ (2006) Effects of surface modification on rheological and mechanical properties of CNT/epoxy composites. Carbon 44:1898–1905

Zhang M, Shao C, Guo Z (2011) Hierarchical nanostructures of copper (II) phthalocyanine on electrospun TiO2 nanofibers: controllable solvothermal-fabrication and enhanced visible photocatalytic properties. ACS Appl Mater Int 3:369–377

Yang J, Tang H, Zhan Y (2012) Photoelectric properties of poly (arylene ether nitriles)–copper phthalocyanine conjugates complex via in situ polymerization. Mater Lett 72:42–45

Yavari F, Fard H, Pashayi K (2011) Enhanced thermal conductivity in a nanostructured phase change composite due to low concentration graphene additives. J Phys Chem C 115:8753–8758

Fu SY, Feng XQ, Lauke B, Mai YW (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos Part B Eng 39:933–961

Acknowledgments

The authors wish to thank for financial support of this work from the National Natural Science Foundation (Nos. 51173021, 51373028, 51403029) and “863” National Major Program of High Technology (2012AA03A212).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, M., Jia, K. & Liu, X. Preparation of hybrid colloidal graphite-copper phthalocyanine and their utilization in polymer composites with enhanced thermal conductivity and mechanical properties. J Polym Res 21, 570 (2014). https://doi.org/10.1007/s10965-014-0570-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-014-0570-9