Abstract

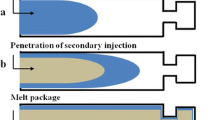

In the current work, the effect of ultra-high molecular weight polyethylene (UHMWPE) and temperature field on the unique double skin-core orientated structure and mechanical properties of high-density polyethylene (HDPE) parts molded by multi-melt multi-injection molding (MMMIM) were investigated using a variety of characterization techniques including rheological experiments, scanning electron microscopy (SEM), synchrotron small-angle X-ray scattering (SAXS), differential scanning calorimetry (DSC) and tensile testing. The SEM results revealed that a distinct double skin-core orientated structure was formed in samples molded via MMMIM. That is, compact lamellar together with typical shish-kebab structures was formed from the skin to the sub-skin, and large area of oriented lamellar was formed again near the core layer due to the significantly improved relaxation time of the UHMWPE/HDPE blend and intensive shear flow resulted from the secondary melt penetration process. Additionally, with increase temperature of the second melt, the oriented lamellar near the core layer tended to develop into irregularly-arranged lamellar and the double skin-core orientated structure weakened gradually. These results were further authenticated by SAXS. Results of tensile testing indicated that with reduced temperature of second melt, samples with higher tensile strength and modulus were obtained.

Similar content being viewed by others

References

Kmetty Á, Bárány T, Karger-Kocsis J (2010) Self-reinforced polymeric materials: a review. Prog Polym Sci 35:1288–1310

Arvidson SA, Khan SA, Gorga RE (2010) Mesomorphic − α-Monoclinic phase transition in isotactic polypropylene: A study of processing effects on structure and mechanical properties. Macromolecules 43:2916–2924

Wang K, Chen F, Li Z, Fu Q (2013) Control of the hierarchical structure of polymer articles via novel processing: From traditional processing toward “structuring” processing. Prog Polym Sci

Lin X, Fin CR, Ren D, Wang K, Coates P (2013) Shear-induced crystallization morphology and mechanical property of high density polyethylene in micro-injection molding. J Polym Res 20:1–12

Wang GL, Zhou YG, Wang SJ, Chen JB, Zhang XL, Lu S (2013) Cylindritic structures of isotactic polypropylene molded by sequential co-injection molding. J Polym Res 20:1–11

Hsiao BS, Yang L, Somani RH, Avila-Orta CA, Zhu L (2005) Unexpected shish-kebab structure in a sheared polyethylene melt. Phys Rev Lett 94:117802

Keller A, Kolnaar HW (1998) Flow-induced orientation and structure formation. II. structure development during processing. Mater Sci Technol

Simis KS, Bistolfi A, Bellare A, Pruitt LA (2006) The combined effects of crosslinking and high crystallinity on the microstructural and mechanical properties of ultra high molecular weight polyethylene. Biomaterials 27:1688–1694

Yang HR, Lei J, Li L, Fu Q, Li ZM (2012) Formation of interlinked shish-kebabs in injection-molded polyethylene under the coexistence of lightly cross-linked chain network and oscillation shear flow. Macromolecules 45:6600–6610

Hossain D, Tschopp M, Ward D, Bouvard J, Wang P, Horstemeyer M (2010) Molecular dynamics simulations of deformation mechanisms of amorphous polyethylene. Polymer 51:6071–6083

Jiang Z, Tang Y, Rieger J, Enderle HF, Lilge D, Roth SV, Gehrke R, Wu Z, Li Z, Men Y (2009) Structural evolution of tensile deformed high-density polyethylene at elevated temperatures: Scanning synchrotron small-and wide-angle X-ray scattering studies. Polymer 50:4101–4111

Pennings A (1965) Kolloid ZZ Polym. 1965, 205, 160.[CrossRef],[CAS] Fractionation of polymers by crystallization from solution. III. The morphology of fibrillar polyethylene crystals grown in solution Pennings, AJ; Kiel, AM. Kolloid Zeitschrift & Zeitschrift fuer Polymer 205:160–162

Hobbs J, Humphris A, Miles M (2001) In-situ atomic force microscopy of polyethylene crystallization.1. crystallization from an oriented backbone. Macromolecules 34:5508–5519

Somani RH, Hsiao BS, Nogales A, Fruitwala H, Srinivas S, Tsou AH (2001) Structure development during shear flow induced crystallization of i-PP: in situ wide-angle X-ray diffraction study. Macromolecules 34:5902–5909

Kornfield JA, Kumaraswamy G, Issaian AM (2002) Recent advances in understanding flow effects on polymer crystallization. Ind Eng Chem Res 41:6383–6392

Bushman A, McHugh A (1997) Transient flow‐induced crystallization of a polyethylene melt. J App Polym Sci 64:2165–2176

Duplay C, Monasse B, Haudin JM, Costa JL (1999) Shear-induced crystallization of polypropylene: influence of molecular structure. Polym Int 48:320–326

Mackley M, Keller A (1973) Flow induced crystallization of polyethylene melts. Polymer 14:16–20

Kimata S, Sakurai T, Nozue Y, Kasahara T, Yamaguchi N, Karino T, Shibayama M, Kornfield JA (2007) Molecular basis of the shish-kebab morphology in polymer crystallization. Science 316:1014–1017

Nogales A, Hsiao B, Somani R, Srinivas S, Tsou A, Balta-Calleja F, Ezquerra T (2001) Shear-induced crystallization of isotactic polypropylene with different molecular weight distributions: in situ small and wide-angle X-ray scattering studies. Polymer 42:5247–5256

Dikovsky D, Marom G, Avila-Orta CA, Somani RH, Hsiao BS (2005) Shear-induced crystallization in isotactic polypropylene containing ultra-high molecular weight polyethylene oriented precursor domains. Polymer 46:3096–3104

Somani RH, Yang L, Hsiao BS, Agarwal PK, Fruitwala HA, Tsou AH (2002) Shear-induced precursor structures in isotactic polypropylene melt by in-situ rheo-SAXS and rheo-WAXD studies. Macromolecules 35:9096–9104

Van Meerveld J, Peters GW, Hütter M (2004) Towards a rheological classification of flow induced crystallization experiments of polymer melts. Rheologica Acta 44:119–134

Goodship V, Love J (2002) Multi-material injection moulding, vol 145. iSmithers Rapra Publishing

Mai F, Wang K, Yao M, Deng H, Chen F, Fu Q (2010) Superior reinforcement in melt-spun polyethylene/multiwalled carbon nanotube fiber through formation of a shish-kebab structure. J Phys Chem B 114:10693–10702

Lei J, Jiang C, Shen KZ (2004) Biaxially self-reinforced high‐density polyethylene prepared by dynamic packing injection molding. I. Processing parameters and mechanical properties. J App Polym Sci 93:1584–1590

Keum JK, Zuo F, Hsiao BS (2008) Formation and stability of shear-induced shish-kebab structure in highly entangled melts of UHMWPE/HDPE blends. Macromolecules 41:4766–4776

Zhang K, Liu Z, Yang B, Yang W, Lu Y, Wang L, Sun N, Yang MB (2011) Cylindritic structures of high-density polyethylene molded by multi-melt multi-injection molding. Polymer 52:3871–3878

Cox W, Merz E (1958) Correlation of dynamic and steady flow viscosities. J Polym Sci 28:619–622

Olley R, Bassett D (1982) An improved permanganic etchant for polyolefines. Polymer 23:1707–1710

Zhai YM, Wang Y, Yang W, Xie BH, Yang MB (2009) Dynamic rheological behavior of copolymerized linear low-density polyethylenes: Effect of molecular weight and its distribution. J Macromol Sci B 48:844–855

Carreau PJ, MacDonald IF, Bird RB (1968) A nonlinear viscoelastic model for polymer solutions and melts—II. Chem Eng Sci 23:901–911

Byron Bird R, Carreau PJ (1968) A nonlinear viscoelastic model for polymer solutions and melts—I. Chem Eng Sci 23:427–434

Huang SX, Lu CJ (2006) Stress relaxation characteristics and extrudate swell of the IUPAC-LDPE melt. J Non-Newtonian Fluid Mech 136:147–156

Des Cloizeaux J (1988) Double reptation vs. simple reptation in polymer melts. Europhysics Lett 5:437

An Y, Gu L, Wang Y, Li YM, Yang W, Xie BH, Yang MB (2012) Morphologies of injection molded isotactic polypropylene/ultra high molecular weight polyethylene blends. Mater Des 35:633–639

An Y, Bao RY, Liu ZY, Wu XJ, Yang W, Xie BH, Yang MB (2012) Unusual hierarchical structures of mini-injection molded isotactic polypropylene/ultrahigh molecular weight polyethylene blends. Eur Polym J 49:538–548

Wang L, Yang MB, Zhang QP, Zhang RY, Wu JJ, Feng JM (2013) Hierarchical crystalline structures and dynamic mechanical properties of injection‐molded bars of HDPE: attributes of temperature field. Polym Adva Technol 24:541–550

Hu W, Frenkel D, Mathot VB (2002) Simulation of shish-kebab crystallite induced by a single prealigned macromolecule. Macromolecules 35:7172–7174

Elmoumni A, Winter HH, Waddon AJ, Fruitwala H (2003) Correlation of material and processing time scales with structure development in isotactic polypropylene crystallization. Macromolecules 36:6453–6461

Yang L, Somani RH, Sics I, Hsiao BS, Kolb R, Fruitwala H, Ong C (2004) Shear-induced crystallization precursor studies in model polyethylene blends by in-situ rheo-SAXS and rheo-WAXD. Macromolecules 37:4845–4859

Hu X, Xu JZ, Zhong GJ, Luo XL, Li ZM (2011) Shear induced crystallization of poly (L-lactide) and poly (ethylene glycol)(PLLA-PEG-PLLA) copolymers with different block length. J Polym Res 18:675–680

Cao W, Wang K, Zhang Q, Du R, Fu Q (2006) The hierarchy structure and orientation of high density polyethylene obtained via dynamic packing injection molding. Polymer 47:6857–6867

Na B, Wang K, Zhang Q, Du RN, Fu Q (2005) Tensile properties in the oriented blends of high-density polyethylene and isotactic polypropylene obtained by dynamic packing injection molding. Polymer 46:3190–3198

Na B, Zhang Q, Wang Y, Fu Q (2004) Orientation effects on the deformation and fracture properties of high‐density polyethylene/ethylene vinyl acetate (HDPE/EVA) blends. Polym Int 53:1078–1086

Su R, Su J, Wang K, Yang C, Zhang Q, Fu Q (2009) Shear-induced change of phase morphology and tensile property in injection-molded bars of high-density polyethylene/polyoxymethylene blends. Eur Polym J 45:747–756

Jose S, Aprem A, Francis B, Chandy M, Werner P, Alstaedt V, Thomas S (2004) Phase morphology, crystallisation behaviour and mechanical properties of isotactic polypropylene/high density polyethylene blends. Eur Polym J 40:2105–2115

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51033003 and 51121001). Particularly, we would also like to express our great thanks to Mr. Chao-liang Zhang for the assistance of SEM observations. The 2D SAXS experiments were kindly performed at the Shanghai Synchrotron Radiation Facility (SSRF) in Shanghai, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, J., Wang, L., Zhang, RY. et al. Formation of double skin-core orientated structure in injection-molded Polyethylene parts: Effects of ultra-high molecular weight Polyethylene and temperature field. J Polym Res 21, 432 (2014). https://doi.org/10.1007/s10965-014-0432-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-014-0432-5