Abstract

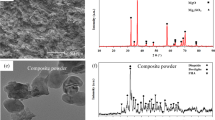

The degradation of magnesium alloys, AZ31B and AZ91E, are under review due to a their ability to degrade under physiological conditions and successively yield an oxidized biocompatible by-product which can safely be absorbed by the body. By exploiting the biodegradability of magnesium alloys, the prospects of developing an unprecedented class of implant are at hand. To do so however, the rate of corrosion of the alloys must be modified in order to better suit physiological conditions. Therefore, anodization was carried out on AZ31B and AZ91E specimens to alter the surface chemistry to reduce the corrosion rates and improve biocompatibility. Scanning electron microscopy, energy dispersive spectroscopy, atomic force microscopy and contact angle meter, were used to characterize and compare the surfaces of untreated and anodized magnesium alloys. Corrosion behavior was evaluated by electrochemical tests using potentiodynamic polarization and electrochemical impedance spectroscopy, to verify changes in corrosion rates as a result of anodization. Finally, a bio-assessment using MTS assays and fluorescent microscopy were carried out to ensure that the anodization process had no compromise on the biocompatibility of the magnesium alloys. The study indicated that the anodization process did alter the surface chemistry of the alloys, yielding slower corrosion rates, while causing no adverse effects in regards to biocompatibility.

Similar content being viewed by others

References

Witte F, Calliess T, Windhagen H. Biodegradable synthetic implant materials: clinical applications and immunological aspects. Orthopade. 2008;37:125–30.

Salahshoor M, Guo Y. Biodegradable orthopedic magnesium-calcium (MgCa) alloys, processing, and corrosion performance. Materials. 2012;5:135–55.

Gray-Munro JE, Seguin C, Strong M. Influence of surface modification on the in vitro corrosion rate of magnesium alloy AZ31. J Biomed Mater Res A. 2009;91:221–30.

Hanada K, Matsuzaki K, Huang X, Chino Y. Fabrication of Mg alloy tubes for biodegradable stent application. Mater Sci Eng C. 2013;33:4746–50.

Zhang E, Xu L, Yu G, Pan F, Yang K. In vivo evaluation of biodegradable magnesium alloy bone implant in the first 6 months implantation. J Biomed Mater Res A. 2009;90:882–93.

Fekry AM, El-Sherif RM. Electrochemical corrosion behavior of magnesium and titanium alloys in simulated body fluid. Electrochim Acta. 2009;54:7280–5.

Song G. Control of biodegradation of biocompatable magnesium alloys. Corros Sci. 2007;49:1696–701.

Pompa L, Rahman ZU, Munoz E, Haider W. Surface characterization and cytotoxicity response of biodegradable magnesium alloys. Mater Sci Eng C. 2015;49:761–8.

Wu G, Ibrahim JM, Chu PK. Surface design of biodegradable magnesium alloys—a review. Surf Coat Technol. 2013;233:2–12.

Walter R, Kannan MB, He Y, Sandham A. Effect of surface roughness on the in vitro degradation behaviour of a biodegradable magnesium-based alloy. Appl Surf Sci. 2013;279:343–8.

Song GL, Atrens A. Corrosion mechanisms of magnesium alloys. Adv Eng Mater. 1999;1:11–33.

Wang J, Tang J, Zhang P, Li Y, Wang J, Lai Y, Qin L. Surface modification of magnesium alloys developed for bioabsorbable orthopedic implants: a general review. J Biomed Mater Res B Appl Biomater. 2012;100:1691–701.

NuLi Y, Yang J, Wang J, Xu J, Wang P. Electrochemical magnesium deposition and dissolution with high efficiency in ionic liquid. Electrochem Solid State Lett. 2005;8:C166–9.

Shashikala AR, Umarani R, Mayanna SM, Sharma AK. Chemical conversion coatings on magnesium alloys—a comparative study. Int J Electrochem Sci. 2008;3:993–1004.

Shi P, Ng WF, Wong MH, Cheng FT. Improvement of corrosion resistance of pure magnesium in Hanks’ solution by microarc oxidation with sol-gel TiO2 sealing. J Alloys Compd. 2009;469:286–92.

Wu HL, Cheng YL, Li LL, Chen ZH, Wang HM, Zhang Z. The anodization of ZK60 magnesium alloy in alkaline solution containing silicate and the corrosion properties of the anodized films. Appl Surf Sci. 2007;253:9387–94.

Chai L, Yu X, Yang Z, Wang Y, Okido M. Anodizing of magnesium alloy AZ31 in alkaline solutions with silicate under continuous sparking. Corros Sci. 2008;50:3274–9.

Textor M, Sittig C, Frauchiger V, Tosatti S, Brunette DM. Properties and biological significance of natural oxide films on titanium and its alloys. In: Brunette DM, Tengvall P, Textor M, Thomson P, editors. Titanium in medicine. Berlin: Springer; 2001.

Li N, Zheng Y. Novel magnesium alloys developed for biomedical application: a review. J Mater Sci Technol. 2013;29:489–502.

Gill PK. Assessment of biodegradable magnesium alloys for enhaned Mechanical & biocompatibility properties. 2012 FIU Electronic Theses and Dissertations. Paper 714.

ASTM (G102–89) Standard practice for calculation of corrosion rates and related information from electrochemical measurements. Annual book of ASTM standards, vol. 89. ATSM; 2010. p. 1–7.

ASTM (G3-89) Standard practice for conventions applicable to electrochemical measurements in corrosion testing.pdf.

Xu L, Zhang E, Yang K. Phosphating treatment and corrosion properties of Mg-Mn-Zn alloy for biomedical application. J Mater Sci Mater Med. 2009;20:859–67.

Salman S, Mori R, Ichino R, Okido M. Effect of anodizing potential on the surface morphology and corrosion property of AZ31 magnesium alloy. Mater Trans. 2010;51(6):1109–13.

El Mahallawy N. AZ91 magnesium alloys: anodizing of using environmental friendly electrolytes. J Surf Eng Mater Adv Technol. 2011;01(02):62–72.

Rahman Z, Pompa L, Haider W. Influence of electropolishing and magnetoelectropolishing on corrosion and biocompatibility of titanium implants. J Mater Eng Perform. 2014;23:3907–15.

Lopez-Alvarez M, Rodriguez-Valencia C, Serra J, Gonalez P. Bio-inspired ceramics: promising scaffolds for bone tissue engineering. Proc Eng. 2013;59:51–8.

Kieswetter K, Schwartz Z, Dean DD, Boyan BD. The role of implant surface characteristics in the healing of bone. Crit Rev Oral Biol Med. 1996;7:329–45.

Ungersbock A, Rahn B. Methods to characterize the surface roughness of metallic implants. J Mater Sci Mater Med. 1994;5:434–40.

Young T. An Essay on the Cohesion of Fluids. Philos Trans R Soc Lond. 1805;95:65–87.

Yuan Y, Lee TR. Contact angle and wetting properties. Surface Science Techniques, vol. 51. Springer: Berlin; 2013. p. 1–34.

De Gennes PG. Wetting: statics and dynamics. Rev Mod Phys. 1985;57:827–63.

Haider W, Munroe N, Pulletikurthi C, Gill P, Amruthaluri S. A comparative biocompatibility analysis of ternary nitinol alloys. J Mater Eng Perform. 2009;18(5–6):760–4.

Feng B, Chen JY, Qi SK, He L, Zhao JZ, Zhang XD. Characterization of surface oxide films on titanium and bioactivity. J Mater Sci Mater Med. 2002;13:457–64.

Ponsonnet L, Reybier K, Jaffrezic N, Comte V, Lagneau C, Lissac M, Martelet C. Relationship between surface properties (roughness, wettability) of titanium and titanium alloys and cell behaviour. Mater Sci Eng C. 2003;23:551–60.

Subbiahdoss G, Grijpma DW, van der Mei HC, Busscher HJ, Kuijer R. Microbial biofilm growth versus tissue integration on biomaterials with different wettabilities and a polymer-brush coating. J Biomed Mater Res A. 2010;94:533–8.

Berg JM, Tymoczko JL, Stryer L. Biochemistry. 5th ed. New York: W. H. Freeman and co; 2006. p. 1120.

Witte F, Fischer J, Nellesen J, Crostack H-A, Kaese V, Pisch A, Beckmann F, Windhagen H. In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials. 2006;27(7):1013–8.

Xin Y. Corrosion behavior of biomedical AZ91 magnesium alloy in simulated body fluids. J Mater Res. 2007;22:2004–11.

Xin Y, Huo K, Tao H, Tang G, Chu PK. Influence of aggressive ions on the degradation behavior of biomedical magnesium alloy in physiological environment. Acta Biomater. 2008;4:2008–15.

Electrochemistry P, Elements C, Equivalent C, Models C. Basics of electrochemical impedance spectroscopy. Appl Note AC. 2010;286:R491–7.

Ates M. Review study of electrochemical impedance spectroscopy and equivalent electrical circuits of conducting polymers on carbon surfaces. Prog Org Coat. 2011;71:1–10.

Chang B-Y, Park S-M. Electrochemical impedance spectroscopy. Annu Rev Anal Chem. 2010;3:207–29.

Song YW, Shan DY, Han EH. Electrodeposition of hydroxyapatite coating on AZ91D magnesium alloy for biomaterial application. Mater Lett. 2008;62:3276–9.

Xu R, Yang X, Suen KW, Wu G, Li P, Chu PK. Improved corrosion resistance on biodegradable magnesium by zinc and aluminum ion implantation atomic concentration (%). Appl Surf Sci. 2012;263:608–12.

Fischer J, Pröfrock D, Hort N, Willumeit R, Feyerabend F. Improved cytotoxicity testing of magnesium materials. Mater Sci Eng B. 2011;176(11):830–4.

Kim K. Scaffold design parameters to simulate the osteogenic signal expression for bone tissue engineering applications. Ph.D. Thesis, University of Maryland, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahman, Z.U., Pompa, L. & Haider, W. Electrochemical characterization and in-vitro bio-assessment of AZ31B and AZ91E alloys as biodegradable implant materials. J Mater Sci: Mater Med 26, 217 (2015). https://doi.org/10.1007/s10856-015-5545-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5545-9