Abstract

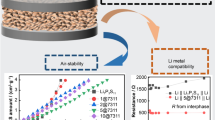

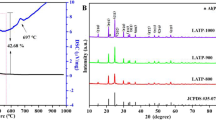

Solid-state electrolyte as a crucial component in all-solid-state batteries should have high Li-ion conductivity and good stability in air. Recently, a new solid Li-ion conductor LiTa2PO8 (LTPO) with theoretical and experimental Li-ion conductivities of 35.3 and 0.25 mS/cm has been reported. Herein, we systematically investigate the ionic conductivity and chemical stability of the LTPO electrolytes sintered by conventional sintering (CS) and hot-pressing sintering (HP) methods. The effects of Li sources, sintering temperature, and the dwelling time are concerned. LTPO pellets using CH3COOLi·2H2O as the Li source sintered by CS method have a room-temperature Li-ion conductivity of 1.86 × 10–4 S/cm with an activation energy of 0.36 eV. A conductivity of 3.12 × 10–4 S/cm with an activation energy of 0.32 eV is achieved by further HP sintering. Moreover, LTPO shows excellent chemical stabilities in air, aqueous solution, and organic solvent and shows a stable cycling performance in the symmetric Li/Li cells and the all-solid-state Li/LiFePO4 batteries with the separation of a thin PEO membrane.

Similar content being viewed by others

References

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414(6861):359–367. https://doi.org/10.1038/35104644

Lin D, Liu Y, Cui Y (2017) Reviving the lithium metal anode for high-energy batteries. Nat Nanotechnol 12(3):194–206. https://doi.org/10.1038/nnano.2017.16

Cheng X-B, Zhang R, Zhao C-Z, Zhang Q (2017) Toward safe lithium metal anode in rechargeable batteries: a review. Chem Rev 117(15):10403–10473. https://doi.org/10.1021/acs.chemrev.7b00115

Lu Y, Tu Z, Archer LA (2014) Stable lithium electrodeposition in liquid and nanoporous solid electrolytes. Nat Mater 13(10):961–969. https://doi.org/10.1038/nmat4041

Armand M, Tarascon J-M (2008) Building better batteries. Nature 451(7179):652–657

Mauger A, Armand M, Julien C, Zaghib K (2017) Challenges and issues facing lithium metal for solid-state rechargeable batteries. J Power Sources 353:333–342

Manthiram A, Yu X, Wang S (2017) Lithium battery chemistries enabled by solid-state electrolytes. Nat Rev Mater. https://doi.org/10.1038/natrevmats.2016.103

Cheng X-B, Zhao C-Z, Yao Y-X, Liu H, Zhang Q (2019) Recent advances in energy chemistry between solid-state electrolyte and safe lithium-metal anodes. Chem 5:74

Goodenough JB, Kim Y (2009) Challenges for rechargeable Li batteries. Chem Mater 22(3):587–603

Wu B, Wang S, Lochala J, Desrochers D, Liu B, Zhang W, Yang J, Xiao J (2018) The role of the solid electrolyte interphase layer in preventing Li dendrite growth in solid-state batteries. Energy Environ Sci 11(7):1803–1810

Fan L, Wei S, Li S, Li Q, Lu Y (2018) Recent progress of the solid-state electrolytes for high-energy metal-based batteries. Adv Energy Mater 8(11):1702657. https://doi.org/10.1002/aenm.201702657

Kamaya N, Homma K, Yamakawa Y, Hirayama M, Kanno R, Yonemura M, Kamiyama T, Kato Y, Hama S, Kawamoto K, Mitsui A (2011) A lithium superionic conductor. Nat Mater 10(9):682–686. https://doi.org/10.1038/nmat3066

Monchak M, Hupfer T, Senyshyn A, Boysen H, Chernyshov D, Hansen T, Schell KG, Bucharsky EC, Hoffmann MJ, Ehrenberg H (2016) Lithium diffusion pathway in Li1. 3Al0. 3Ti1. 7 (PO4) 3 (LATP) superionic conductor. Inorganic Chem 55(6):2941–2945

Li Y, Zhou W, Chen X, Lu X, Cui Z, Xin S, Xue L, Jia Q, Goodenough JB (2016) Mastering the interface for advanced all-solid-state lithium rechargeable batteries. Proc Natl Acad Sci U S A 113(47):13313–13317. https://doi.org/10.1073/pnas.1615912113

Murugan R, Thangadurai V, Weppner W (2007) Fast lithium ion conduction in garnet-type Li7La3Zr2O12. Angew Chem Int Ed 46(41):7778–7781

Cho Y-H, Wolfenstine J, Rangasamy E, Kim H, Choe H, Sakamoto J (2012) Mechanical properties of the solid Li-ion conducting electrolyte: Li0. 33La0. 57TiO3. J Mater Sci 47(16):5970–5977. https://doi.org/10.1007/s10853-012-6500-5

Luo J, Zhong S, Huang Z, Huang B, Wang C-A (2019) High Li+-conductive perovskite Li3/8Sr7/16Ta3/4Zr1/4O3 electrolyte prepared by hot-pressing for all-solid-state Li-ion batteries. Solid State Ionics 338:1–4

Bohnke O (2008) The fast lithium-ion conducting oxides Li3xLa2/3 − xTiO3 from fundamentals to application. Solid State Ionics 179:9–15. https://doi.org/10.1016/j.ssi.2007.12.022

Huang B, Xu B, Li Y, Zhou W, You Y, Zhong S, Wang C-A, Goodenough JB (2016) Li-ion conduction and stability of perovskite Li3/8Sr7/16Hf1/4Ta3/4O3. ACS Appl Mater Interfaces 8(23):14552–14557

Huang B, Zhong S, Luo J, Huang Z, Wang CA (2019) Highly dense perovskite electrolyte with a high Li+ conductivity for Li–ion batteries. J Power Sources 429:75–79

Belous A, Kolbasov G, Kovalenko L, Boldyrev E, Kobylianska S, Liniova B (2018) All solid-state battery based on ceramic oxide electrolytes with perovskite and NASICON structure. J Solid State Electrochem 22(8):2315–2320

Li Y, Chen X, Dolocan A, Cui Z, Xin S, Xue L, Xu H, Park K, Goodenough JB (2018) Garnet electrolyte with an ultralow interfacial resistance for Li-metal batteries. J Am Chem Soc 140(20):6448–6455

Wolfenstine J, Allen JL, Read J, Sakamoto J (2013) Chemical stability of cubic Li7La3Zr2O12 with molten lithium at elevated temperature. J Mater Sci 48(17):5846–5851. https://doi.org/10.1007/s10853-013-7380-z

Geiger CA, Alekseev EV, Lazic B, Fisch M, Armbruster T, Langner R, Fechtelkord M, Kim N, Pettke T, Weppner W (2011) Crystal chemistry and stability of “Li7La3Zr2O12” garnet: a fast lithium-ion conductor. Inorg Chem 50(3):1089–1097. https://doi.org/10.1021/ic101914e

Inada R, Kimura K, Kusakabe K, Tojo T, Sakurai Y (2014) Synthesis and lithium-ion conductivity for perovskite-type Li3/8Sr7/16Ta3/4Zr1/4O3 solid electrolyte by powder-bed sintering. Solid State Ionics 261:95–99

Kim J, Kim J, Avdeev M, Yun H, Kim S-J (2018) LiTa2PO8: a fast lithium-ion conductor with new framework structure. J Mater Chem A 6(45):22478–22482. https://doi.org/10.1039/c8ta09170f

Hussain F, Li P, Li Z (2019) Theoretical insights into li-ion transport in LiTa2PO8. J Phys Chem C 123(32):19282–19287. https://doi.org/10.1021/acs.jpcc.9b03313

Li Y, Wang Z, Cao Y, Du F, Chen C, Cui Z, Guo X (2015) W-doped Li7La3Zr2O12 ceramic electrolytes for solid state Li-ion batteries. Electrochim Acta 180:37–42

Kang J, Chung H, Doh C, Kang B, Han B (2015) Integrated study of first principles calculations and experimental measurements for Li-ionic conductivity in Al-doped solid-state LiGe2(PO4)3 electrolyte. J Power Sources 293:11–16

Chen K, Huang M, Shen Y, Lin Y, Nan CW (2012) Enhancing ionic conductivity of Li0.35La0.55TiO3 ceramics by introducing Li7La3Zr2O12. Electrochim Acta 80:133–139

Wang Y, Richards WD, Ong SP, Miara LJ, Kim JC, Mo Y, Ceder G (2015) Design principles for solid-state lithium superionic conductors. Nat Mater 14(10):1026–1031. https://doi.org/10.1038/nmat4369

Bachman JC, Muy S, Grimaud A, Chang HH, Pour N, Lux SF, Paschos O, Maglia F, Lupart S, Lamp P, Giordano L, Shao-Horn Y (2016) Inorganic solid-state electrolytes for lithium batteries: mechanisms and properties governing ion conduction. Chem Rev 116(1):140–162. https://doi.org/10.1021/acs.chemrev.5b00563

Zhou W, Wang S, Li Y, Xin S, Manthiram A, Goodenough JB (2016) Plating a dendrite-free lithium anode with a polymer/ceramic/polymer sandwich electrolyte. J Am Chem Soc 138(30):9385–9388. https://doi.org/10.1021/jacs.6b05341

Bousnina M, Dujardin R, Perriere L, Giovannelli F, Guegan G, Delorme F (2018) Synthesis, sintering, and thermoelectric properties of the solid solution La 1–x Sr x CoO 3±δ (0≤ x≤ 1). J Adv Ceram 7(2):160–168

Frost RL, Weier ML, Erickson KL (2004) Thermal decomposition of struvite. J Therm Anal Calorim 76(3):1025–1033

Wang PB, Luo MZ, Zheng JC, He ZJ, Tong H, Yu WJ (2018) Comparative Investigation of 0.5Li2MnO3.0.5LiNi0.5Co0.2Mn0.3O2 cathode materials synthesized by using different lithium sources. Front Chem 6:159. https://doi.org/10.3389/fchem.2018.00159

Li X-q, Guo H-j, Li L-m, Li X-h, Wang Z-x, Ou H, Xiang K-x (2011) Effects of calcination temperature on properties of Li2SiO3 for precursor of Li2FeSiO4. Trans Nonferrous Metals Soc China 21(3):529–534. https://doi.org/10.1016/s1003-6326(11)60747-4

Viswabaskaran V, Gnanam F, Balasubramanian M (2003) Mullitisation behaviour of calcined clay–alumina mixtures. Ceram Int 29(5):561–571

Ma C, Rangasamy E, Liang C, Sakamoto J, More KL, Chi M (2015) Excellent stability of a lithium-ion-conducting solid electrolyte upon reversible Li(+) /H(+) exchange in aqueous solutions. Angew Chem Int Ed Engl 54(1):129–133. https://doi.org/10.1002/anie.201408124

Li Y, Xu B, Xu H, Duan H, Lü X, Xin S, Zhou W, Xue L, Fu G, Manthiram A (2017) Hybrid polymer/garnet electrolyte with a small interfacial resistance for lithium-ion batteries. Angew Chem Int Ed 56(3):753–756

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (NSFC-Nos. 51872159 and 51572145), Beijing Natural Science Foundation and Haidian original Innovation Foundation (No. L172039).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Kyle Brinkman.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Huang, B., Xu, B., Zhang, J. et al. Li-ion conductivity and stability of hot-pressed LiTa2PO8 solid electrolyte for all-solid-state batteries. J Mater Sci 56, 2425–2434 (2021). https://doi.org/10.1007/s10853-020-05324-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05324-9